Controller for solid oxide fuel cell (SOFC) system

A fuel cell system and solid oxide technology, applied in the direction of fuel cell additives, etc., can solve the problems of being difficult to meet the control task requirements of the SOFC system, difficult to meet the control algorithm of the SOFC system, general structure, and poor pertinence, etc., to achieve The effect of clear control structure, good electromagnetic compatibility and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

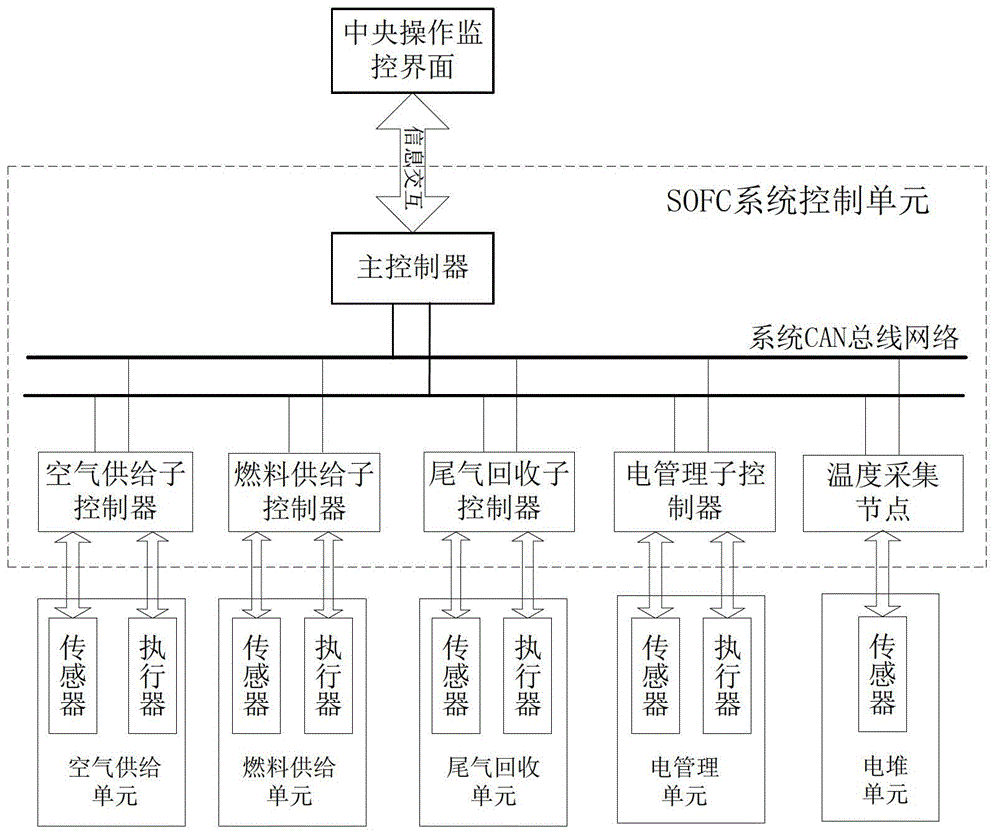

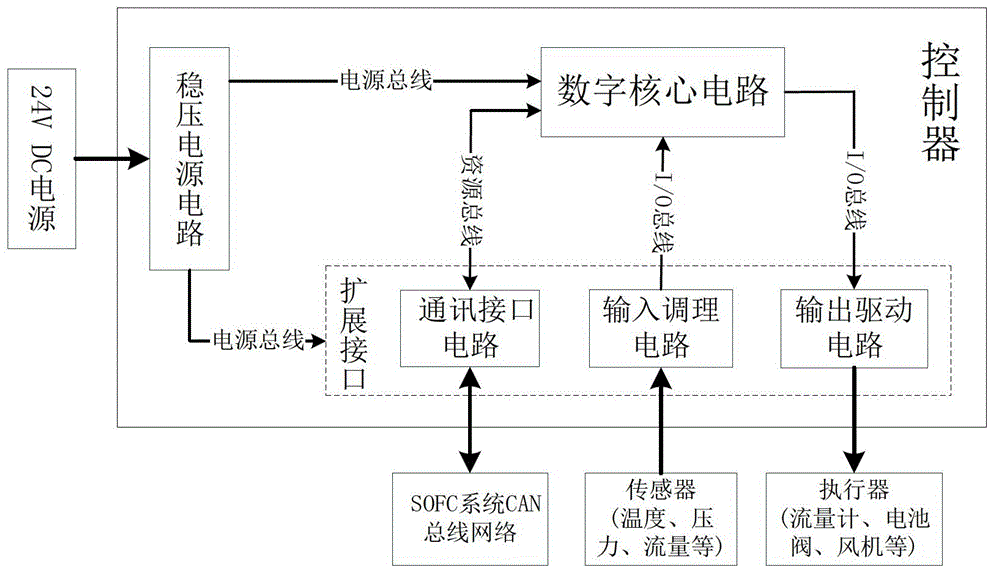

[0023] figure 1 Shown is a block diagram of the solid oxide fuel cell control system. The solid oxide fuel cell (SOFC) system includes a functional unit, a control unit and a central operation monitoring interface, where the functional unit includes a stack unit, an air supply unit, a fuel supply unit, an exhaust gas recovery unit, and an electrical management unit. Each unit contains temperature, Sensors such as flow and pressure, and actuators such as solenoid valves, flow meters, and speed fans; the control unit includes a main controller, unit sub-controllers, and temperature acquisition nodes, which are connected by CAN communication network; the central operation monitoring interface adopts Fameview Industrial PC with configuration software.

[0024] The main controller of the control unit is connected downwardly with the sub-controllers of each unit through the CAN network bus, and upwardly connected with the monitoring PC through serial port communication, which mainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com