Production method of 4-hexene-3-one by catalyzed dehydration of 4-hydroxy-3-hexanone

A technology for catalytic dehydration and hexanone, applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of high reaction temperature, low space velocity, poor catalyst activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 6.2 g of Zr (NO 3 ) 4 ·5H 2 O was dissolved in 208 grams of deionized water. After the dissolution was complete, 16 grams of cetyltrimethylammonium bromide (CTAB) was added, and it was fully stirred to dissolve it. After the solution was clarified, 80 grams of ethyl orthosilicate was added. Zr: Si: CTAB (mol) = 1: 24.5: 3, under stirring, add concentrated ammonia water dropwise to pH = 10, continue to stir for 2 hours, age for 12 hours, the sample is filtered and washed with deionized water until there are no impurity ions Dry at 100 °C to obtain mesoporous ZrO 2 -SiO 2 vector.

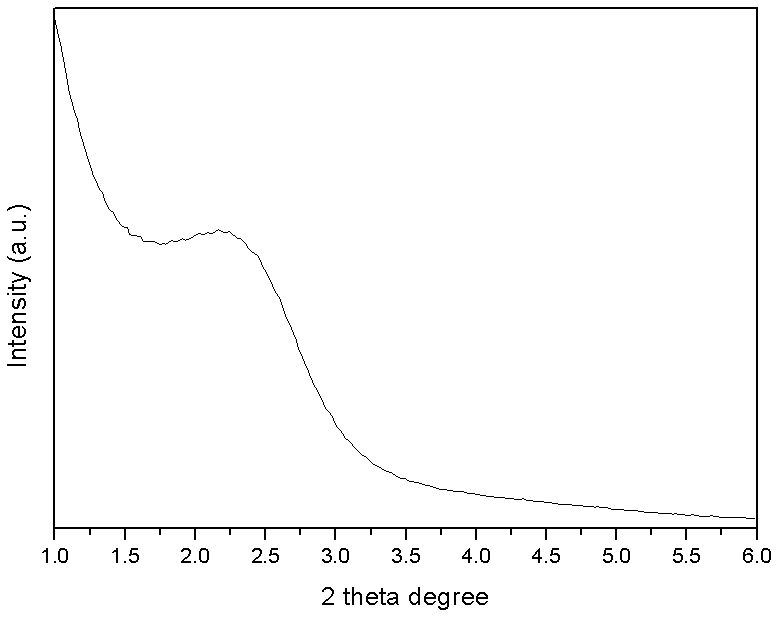

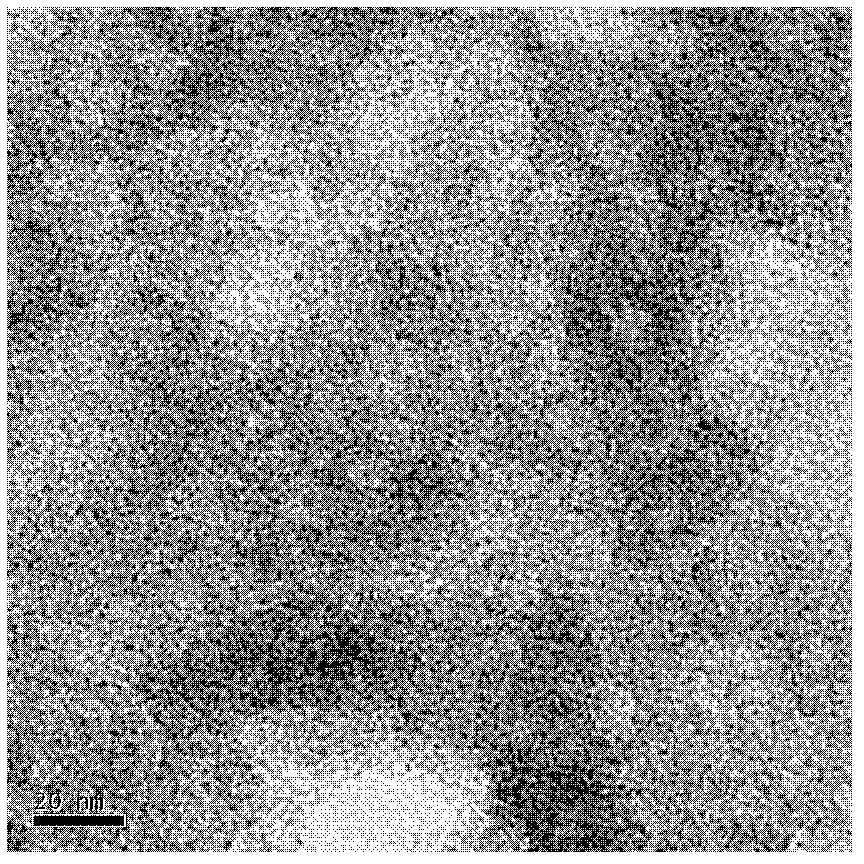

[0023] The carrier was ground to ≤100 mesh, and then impregnated with an equal volume of 0.5 mol / L ammonium tungstate solution for 12 hours, dried in a water bath, and calcined at 700 °C for 5 hours to obtain the catalyst sample WO 3 / ZrO 2 -SiO 2 , so that W:Zr:Si (mol)=0.16:1:24.5. The XRD pattern of the catalyst is shown in figure 1 , see TEM pictures image 3 . Its specific surfa...

Embodiment 2

[0026] According to the steps and conditions of [Example 1], only using tungstic acid, W:Zr:Si (mol)=0.21:1:24.5, calcination at 650°C for 10 hours. The pore size is 4.5 nanometers.

[0027] The performance evaluation of the catalyst was performed according to the steps and conditions of [Example 1], except that the reaction temperature was 270°C and the liquid space velocity was 3 hours. -1 , and the reaction results are shown in Table 1.

Embodiment 3

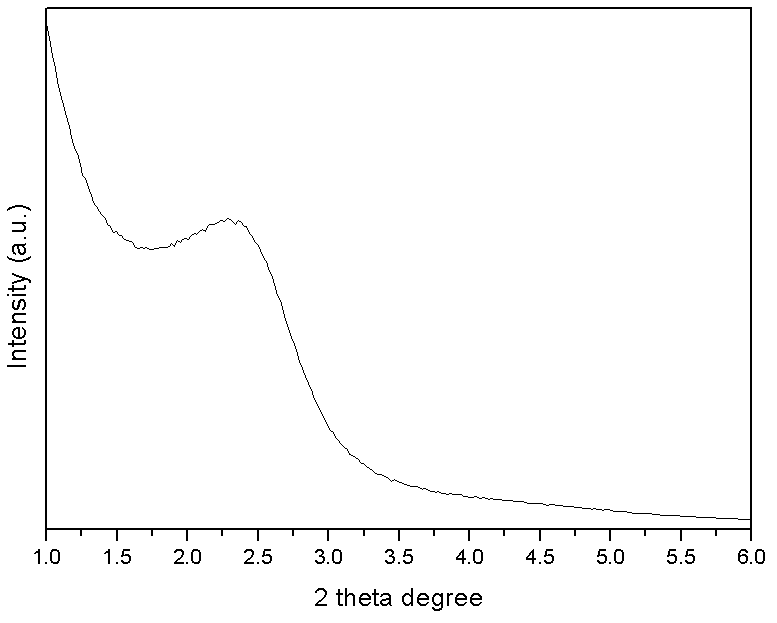

[0029] According to the steps and conditions of [Example 1], only use ZrOCl 2 , silica sol, polyoxypropylene polyoxyethylene copolymer (P123), Zr:Si:P123 (mol)=1:11.3:0.5, aging for 24 hours. Only molybdic acid was used, Mo:Zr:Si (mol)=0.18:1:11.3, excess impregnation for 12 hours, and calcination at 650°C for 10 hours. The XRD pattern of the catalyst is shown in figure 2 , see TEM pictures Figure 4 . Its specific surface area is 1015.09 meters 2 / g, the hole volume is 0.85 cm 3 / g, with a pore size of 3.4 nm.

[0030]The performance evaluation of the catalyst was carried out according to the steps and conditions of [Example 1], except that the reaction temperature was 340°C and the liquid space velocity was 8 hours. -1 , and the reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com