Felt proofing machine-washing finishing method for wool fabric

A felting machine and fabric technology, used in fiber treatment, physical treatment, biochemical fiber treatment, etc., can solve the problems of large differences in scale peeling, large pollution, uneven fiber scale peeling, etc., to improve wearing performance and Durability, improved internal and external uniformity, improved effect of scaling uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

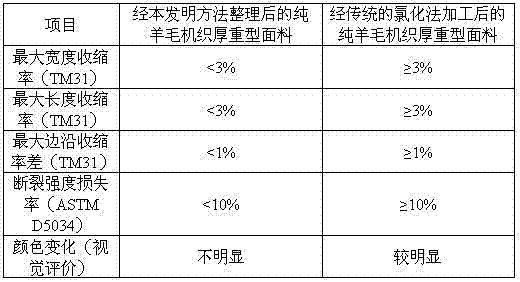

[0028] For pure wool woven heavy-duty fabrics (yarn count: 40 / 3×40 / 2; density: 148×192 threads / 10cm; weight: 355g / m 2 ) for anti-felting machine washable finishing treatment, the specific treatment process is:

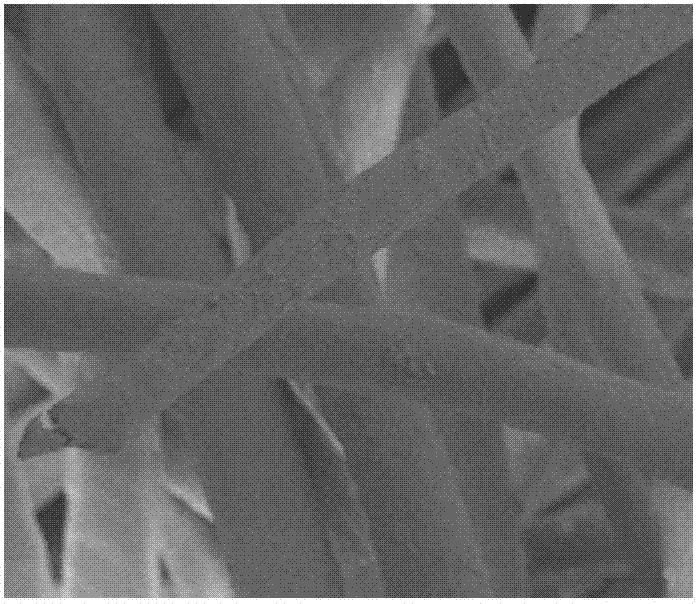

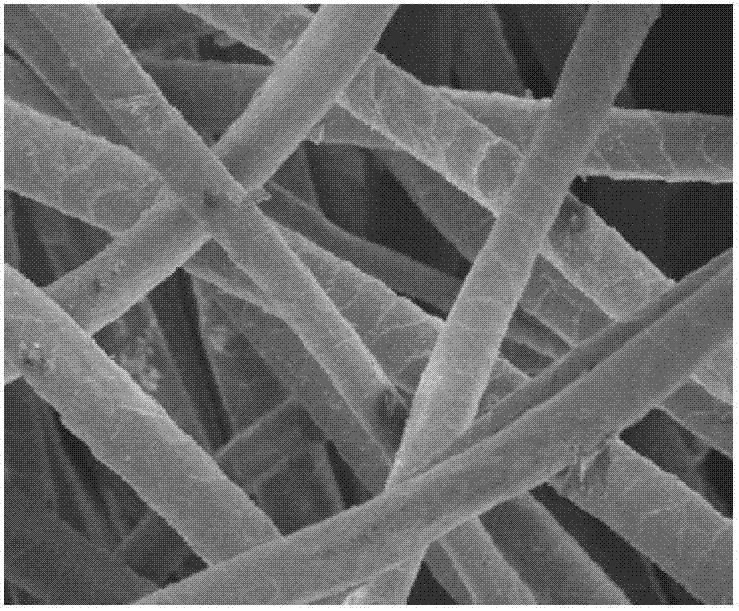

[0029] ① Mild chlorination pretreatment under the action of ultrasonic waves: immerse the wool fabric in a chlorinated solution with a concentration of 1.5% for mild chlorination pretreatment; treatment conditions: the frequency of the ultrasonic processor used is set to 25kHz, and the treatment temperature is 32 ℃, the treatment time is 40 minutes, and the consumption of the chlorinating agent adopted is 1.6% of the weight of the woolen fabric.

[0030] In this embodiment, the ultrasonic processor adopts any existing mature ultrasonic processor; Basolan is used as a chlorinating agent (such as BAOLAN88 (Basolan 88), which is an organic chlorine-releasing compound) to The scale layer on the wool surface is slowly eroded, making the wool surface smooth, making the woo...

Embodiment 2

[0041] For pure wool woven heavy-duty fabrics (yarn count: 40 / 3×40 / 2; density: 148×192 threads / 10cm; weight: 355g / m2 ) for anti-felting machine washable finishing treatment, the specific treatment process is:

[0042] ① Mild chlorination pretreatment under the action of ultrasonic waves: immerse the wool fabric in a chlorinated solution with a concentration of 1% for mild chlorination pretreatment; treatment conditions: the frequency of the ultrasonic processor used is set to 15kHz, and the treatment temperature is 20 ℃, the treatment time is 30 minutes, and the consumption of the chlorinating agent adopted is 1% of the weight of the woolen fabric.

[0043] ②Reductive dechlorination treatment: add a reducing agent to the chlorinated solution soaked in wool fabric for reduction dechlorination treatment; treatment conditions: the amount of reducing agent is 4% of the weight of the wool fabric, the pH value is adjusted to 6, and the treatment temperature is 20°C, the treatment t...

Embodiment 3

[0049] For pure wool woven heavy-duty fabrics (yarn count: 40 / 3×40 / 2; density: 148×192 threads / 10cm; weight: 355g / m 2 ) for anti-felting machine washable finishing treatment, the specific treatment process is:

[0050] ① Mild chlorination pretreatment under the action of ultrasonic waves: immerse the wool fabric in a chlorinated solution with a concentration of 2% for mild chlorination pretreatment; treatment conditions: the frequency of the ultrasonic processor used is set to 40kHz, and the treatment temperature is 35 ℃, the treatment time is 50 minutes, and the consumption of the chlorinating agent adopted is 2% of the weight of the woolen fabric.

[0051] ②Reductive dechlorination treatment: add a reducing agent to the chlorinated solution soaked in wool fabric for reduction dechlorination treatment; treatment conditions: the amount of reducing agent is 7% of the weight of the wool fabric, the pH value is adjusted to 8.5, and the treatment temperature is 35°C, the treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com