Device and mass spectrometry for direct electrospray ionization of sample on microfluidic chip

A microfluidic chip and electrospray ionization technology are applied in the direction of material analysis, measurement device, and material analysis by electromagnetic means, achieving the effect of low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

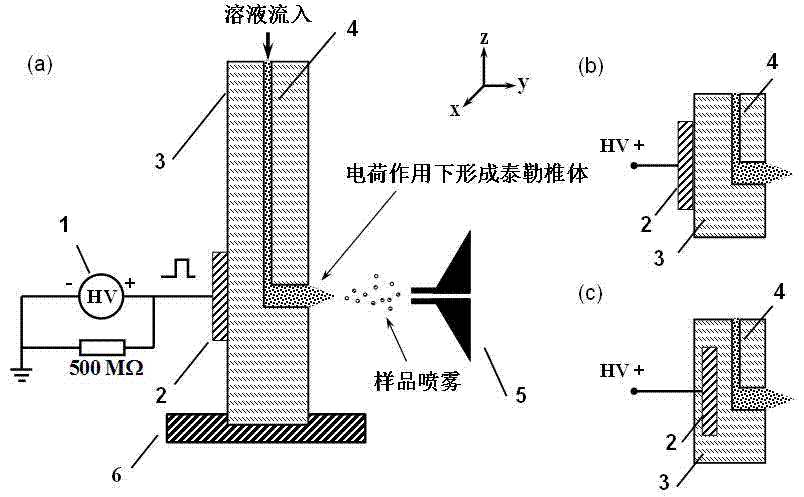

[0036] Such as figure 1 As shown, the microfluidic chip 3 is fixed on its three-dimensional adjustment platform 6 . Adjust the three-dimensional adjustment platform so that the outlet of the microchannel 4 is located 5-10 mm in front of the inlet of the mass spectrometer 5, so that ionization can be better during ionization. Pass the liquid to be tested into the sample microchannel 4, and deliver the liquid to the outlet of the microchannel. Turn on the pulse power supply 1, output pulsed DC high-voltage electrical signals to the plate 2, the output frequency is 1 Hz ~ 10 kHz, and the output voltage is 3 ~ 15 kV. The specific output frequency and output voltage need to be determined according to the type of sample to be analyzed and Specific adjustments such as flow rate.

[0037] When the power supply 1 is at the rising edge of the pulse output, the solution will form an electric double layer due to charging (negative charges are gathered near the electrode, and positive ch...

Embodiment 2

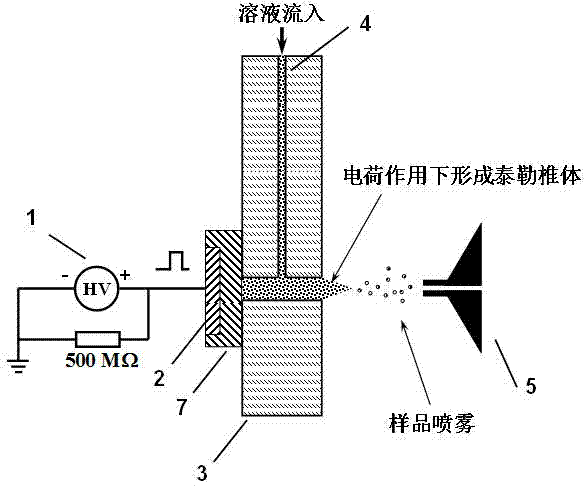

[0040] This embodiment is similar to the device of embodiment 1, except that the design of the outlet of the microchannel of the microfluidic chip used in combination is different from that shown in example 1. Such as figure 2 As shown, the sample micro pool at the outlet of the micro channel has openings on the upper and lower sides of the chip. At this time, an insulating layer 7 (with a thickness of 0.5 mm to 2 mm) needs to be coated on the surface of the electrode 2 . The electrode 2 covered with the insulating layer 7 is placed at one end of the outlet of the microchannel, and the other end is directed to the mass spectrometry inlet. As described in Example 1, after the sample flows into the sample microcell through the sample microchannel 4, under the action of the pulsed high voltage output by the power supply 2, sample ions are generated for detection by the mass spectrometer 5.

Embodiment 3

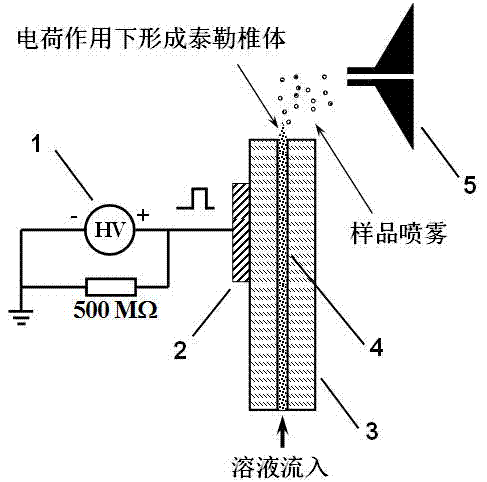

[0042] This embodiment is similar to the device of embodiment 1, except that the design of the outlet of the microchannel of the microfluidic chip used in combination is different from that shown in example 1. The outlet of the sample microchannel 4 does not adopt the design of the sample microcell, and the sample flows out directly in the microchannel. At this time, if image 3 As shown, the electrode 2 needs to be placed on the side of the chip near the outlet of the sample microchannel 4 . As described in Example 1, after the sample flows through the sample microchannel 4 to the outlet of the channel, under the action of the pulsed high voltage output by the power supply 2 , sample ions are generated for detection by the mass spectrometer 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com