Large current pin structure of coil wound rotor motor

A wound rotor motor, high current technology, applied in the direction of circuits, insulated cables, electrical components, etc., can solve the problems of limited, large current of motor wound rotor, etc., and achieve the effect of low cost, high reliability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing this patent is further described

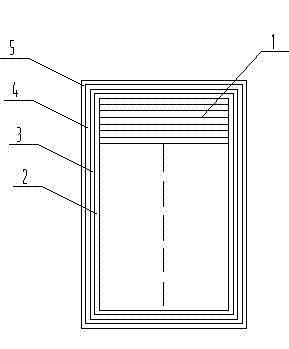

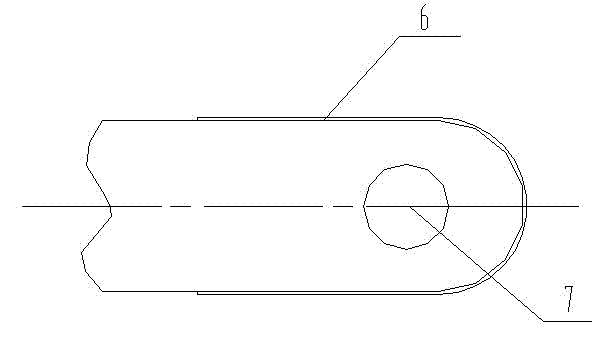

[0011] A high-current lead wire structure of a wound rotor motor, including several layers of soft-state copper skin 1, imide film 2, silicone rubber self-adhesive tape 3, polyester glass tape 4, the soft-state copper skin 1 is selected according to the maximum current-carrying requirements of the rotor The number of layers, the outer cross half of the soft state copper skin 1 is covered with imide film 2 and silicone rubber self-adhesive tape 3, the number of coating layers is selected according to the ground pressure requirements; After ground insulation, a layer of epoxy self-drying paint 5 is coated on the outside; the end of the lead wire structure is plated with a tin-plated layer 6, and an inner hole 7 is provided for connection. The invention effectively improves the reliability of the motor, reduces the cost of materials, and has good process operability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com