Current source type bidirectional multipulse converter based on polarity-variable direct current bus

A technology of bidirectional converter and DC bus, applied in the direction of conversion equipment with reversible, can solve the problem that energy cannot be transmitted in both directions, and achieve simple control loop and filter design, volume reduction, and volume reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

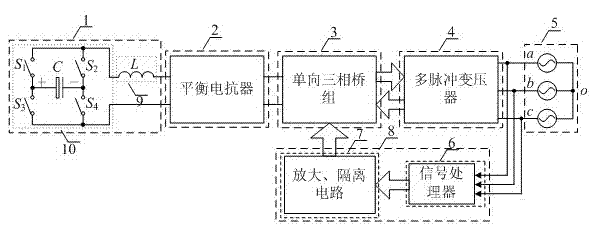

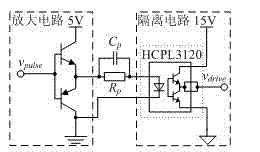

[0037] attached figure 1 A schematic structural diagram of the current source bidirectional multi-pulse converter based on the variable polarity DC bus of the present invention is given, including a DC side circuit (1), a reversible three-phase bridge group (3), a multi-pulse transformer (4), A three-phase AC power supply (5) and a control circuit (8). When the system is a 12- or 24-pulse bidirectional converter, it is better to connect a balance reactor (2) between the DC side circuit (1) and the reversible three-phase bridge group (3) to realize the current sharing of each three-phase bridge. The DC side circuit (1) is composed of a filter inductor (9) and a polarity-selectable DC bus circuit (10). The optional polarity DC bus circuit (10) is composed of switching tubes with double-quadrant voltage and single-quadrant current or composite switching tubes to form a single-phase bridge, and the two ends of the DC load are respectively connected to the midpoint of the two brid...

Embodiment 2

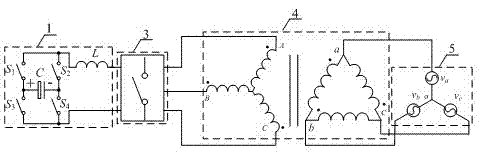

[0040] Such as image 3 As shown, the structure schematic diagram of the isolated 6-pulse bidirectional converter in the present invention. In this structure, no balance reactor (2) is connected between the DC side circuit (1) and the unidirectional three-phase bridge group (3), and the two ends of each three-phase bridge are connected to the same polarity terminals, and then connected to the two ends of the DC side circuit , the midpoints of each bridge arm are sequentially connected to the corresponding interface of the multi-pulse transformer.

[0041]

Embodiment 3

[0043] Such as Figure 4 As shown, the self-coupling type 12-pulse bidirectional converter structure of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com