Granulating and coating process of esomeprazole magnesium contained in esomeprazole magnesium enteric-coated tablet

A technology of esomeprazole magnesium and enteric-coated tablets, which is applied to medical preparations containing active ingredients, pill delivery, organic active ingredients, etc. It can solve the problems of unqualified product content uniformity and achieve good drug release characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A kind of preparation method of esomeprazole magnesium enteric-coated tablet is as follows: first make esomeprazole magnesium granule, pass through isolation layer coating, enteric layer coating successively again, make esomeprazole magnesium enteric coating Dissolve the granules, and finally mix the esomeprazole magnesium enteric-coated granules with auxiliary materials for tableting to obtain esomeprazole magnesium enteric-coated tablets;

[0059] The enteric-coated tablets are prescribed as follows:

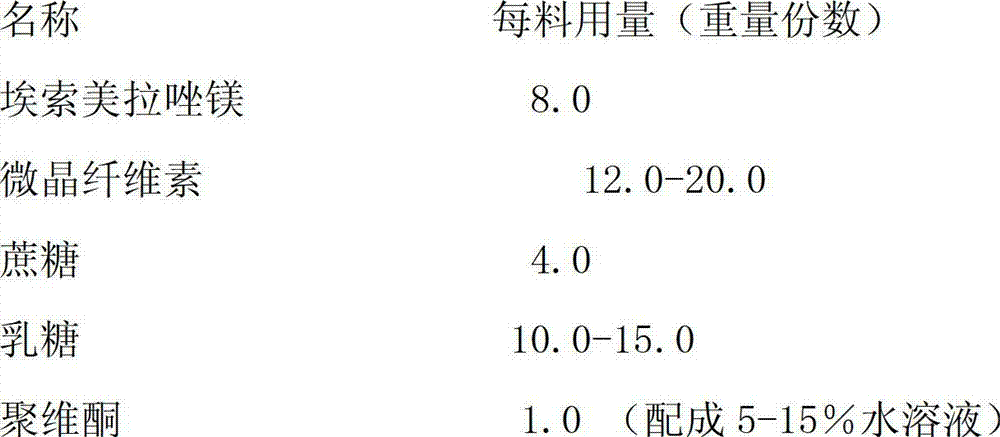

[0060] 1. Prescription of Esomeprazole Magnesium Granules:

[0061]

[0062] 2. Prescription of Esomeprazole Magnesium Isolation Layer Coating Solution:

[0063]

[0064] 3. Prescription of Esomeprazole Magnesium Enteric Layer Coating Solution

[0065]

[0066]

[0067] The granulation and coating process steps of esomeprazole magnesium in the above-mentioned esomeprazole magnesium enteric-coated tablets are as follows:

[0068] 1. Granulation:

[0069] ...

Embodiment 2

[0090] The preparation method is basically the same as in Example 1, except that:

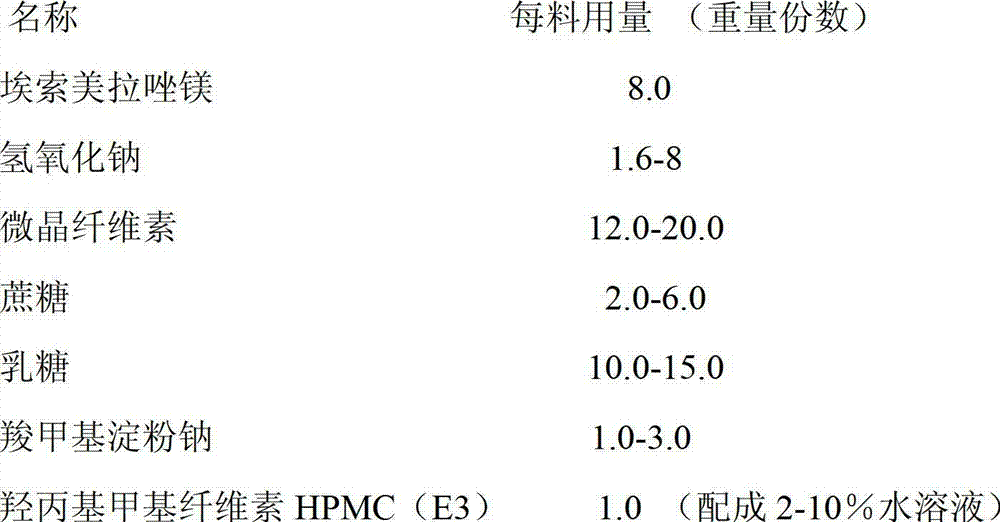

[0091] 1. Prescription of Esomeprazole Magnesium Granules (the dosage unit of each material is kg):

[0092]

[0093] 2. Prescription of Esomeprazole Magnesium Isolation Layer Coating Solution (the dosage unit of each material is kg):

[0094]

[0095]

[0096] 3. Prescription of Esomeprazole Magnesium Enteric-coated Layer Coating Solution (the dosage unit of each material is kg)

[0097]

[0098] Granulation step (3), put the mixed powder (1) and the prescribed amount of microcrystalline cellulose in a three-phase wet granulator and mix for 4 minutes, add povidone aqueous solution (2), and stir for 10 minutes to make suitable granules ; Granulation step (4), the wet granules are dried in a boiling dryer, and the temperature of the material reaches 40°C, and the drying is completed.

[0099] Isolation layer coating step (3), when the particle temperature in the boiling coating mac...

Embodiment 3

[0101] The preparation method is basically the same as in Example 1, except that:

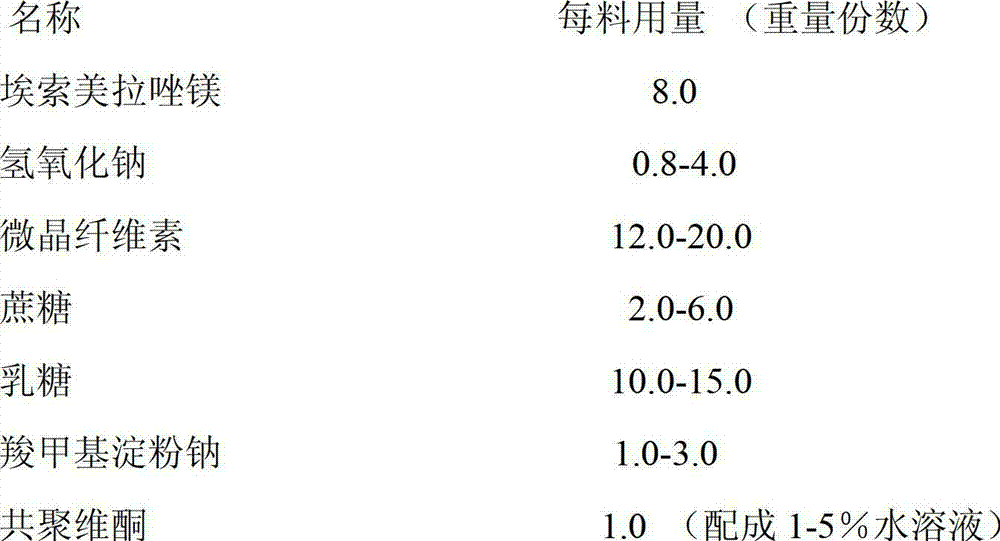

[0102] Prescription of Esomeprazole Magnesium Granules (the dosage unit of each material is kg):

[0103]

[0104]

[0105] 2. Prescription of Esomeprazole Magnesium Isolation Layer Coating Solution (the dosage unit of each material is kg):

[0106]

[0107] 3. Prescription of Esomeprazole Magnesium Enteric-coated Layer Coating Solution (the dosage unit of each material is kg)

[0108]

[0109] Granulation step (3), put the mixed powder (1) and the prescribed amount of microcrystalline cellulose in a three-phase wet granulator and mix for 3 minutes, add povidone aqueous solution (2), and stir for 9 minutes to make suitable granules ; Granulation step (4), the wet granules are dried in a boiling dryer, and the material temperature reaches 38°C, and the drying is completed.

[0110] Isolation layer coating step (3), when the particle temperature in the boiling coating machine reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com