Method for detecting carbide in steel

A carbide and steel technology, applied in the direction of electrochemical variables of materials, etc., can solve the problems of long life evaluation time of materials, complicated experimental devices, and unsuitable for industrial field detection, etc., to achieve rapid testing and result analysis, simple sample preparation, and testing. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The content of the present invention will be described in further detail below through specific examples. Unless otherwise specified, the raw materials, reagents or devices used in the examples can be obtained from conventional commercial channels, or can be obtained through prior art methods. Unless otherwise specified, experiments or testing methods are conventional methods in the art.

[0051] Taking the detection of carbide content in P92 heat-resistant steel tempered at different times as an example, the detection method of the embodiment of the present invention will be described below.

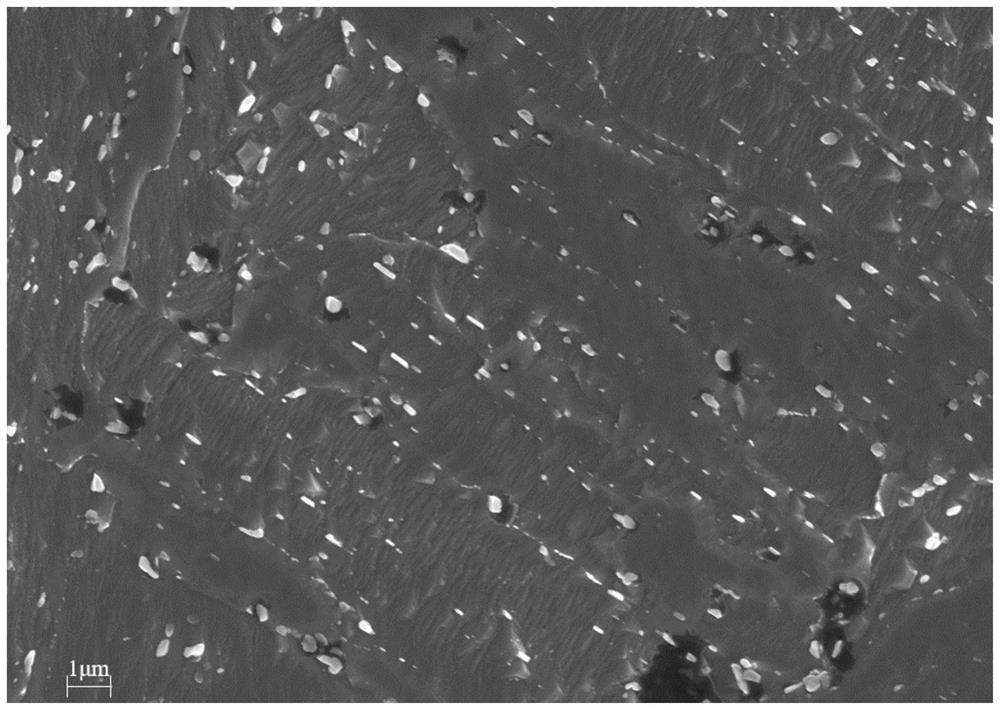

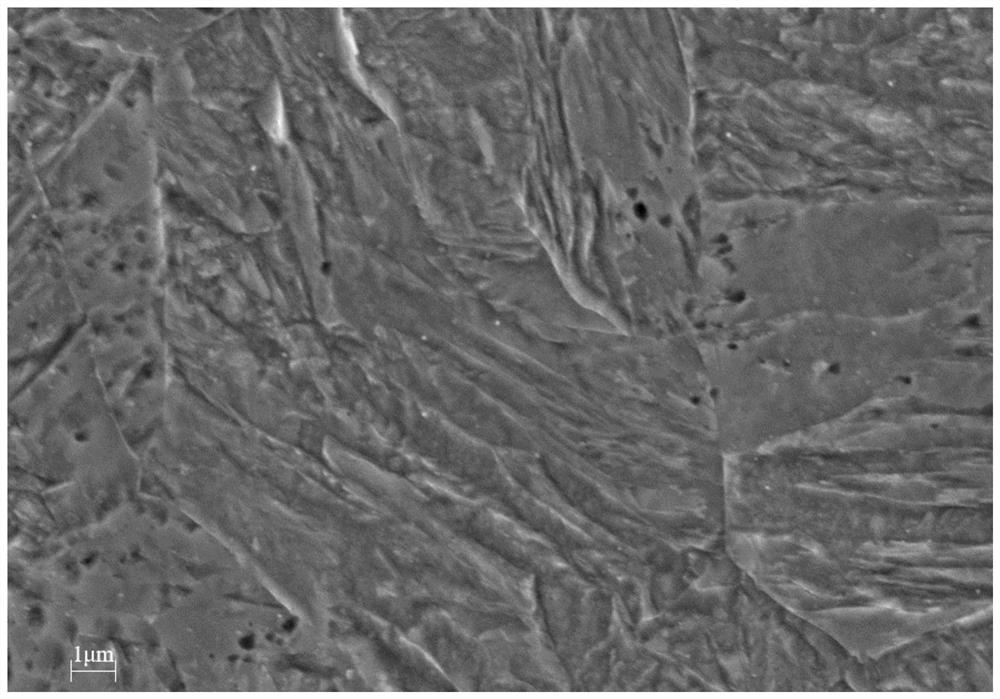

[0052] In order to illustrate that the tempered samples contain carbides, the microscopic morphology of the samples tempered at different times was observed by scanning electron microscopy (SEM). P92 steel samples for comparison. attached figure 1 Shown is the scanning electron micrograph of carbide-containing P92, with figure 2 Shown is the SEM image of carbide-free P92.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com