Water-based cleaning solution for glass substrate and method for cleaning glass substrate by using same

A technology of water-based cleaning liquid and glass substrate, which is applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of high recycling cost, solvent recycling, environmental damage, etc., and achieve cleaning effect Good, easy to use, and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

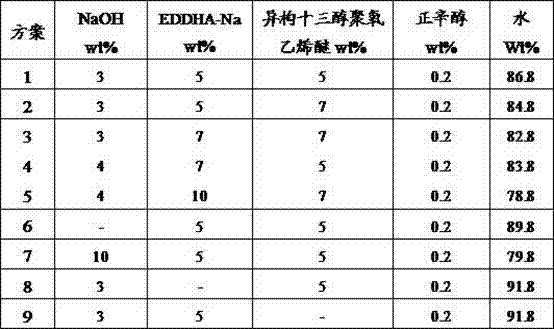

[0034] This embodiment provides five kinds of proportioning schemes, each component and proportioning content are shown in Table 1. After the proportioning is completed, the components are mixed and stirred evenly at room temperature to obtain the glass substrate water-based cleaning solution provided by the present invention.

[0035]

[0036] Table 1

[0037] This embodiment further provides a method for cleaning a glass substrate using the above-mentioned water-based cleaning solution. First, add the above-mentioned cleaning solution into an ultrasonic cleaner, raise the temperature to 40°C, put the glass substrate in the cleaning solution, turn on the ultrasonic wave, and clean 3 minutes or so. Next, wash the cleaned glass panel in deionized water at 40° C. under the same cleaning conditions for about 3 minutes, and then dry it with an air knife.

[0038] It is assumed that the cleaning effect of the cleaning agent is evaluated from the following aspects:

[0039] A-...

Embodiment 2

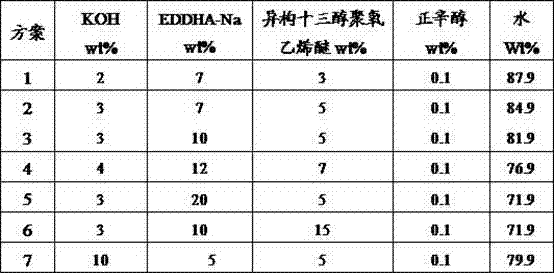

[0056] In this example, the above-mentioned inorganic alkaline substances were replaced with KOH, and the rest of the substances remained unchanged, and 7 schemes were provided, each of which contained different components, and the cleaning ability of the water-based cleaning solution for glass substrates in this example was tested. Each component and its percentage content are as shown in Table 3:

[0057]

[0058] table 3

[0059] Likewise, the present invention also provides a method for cleaning a glass substrate using the above-mentioned water-based cleaning solution.

[0060]Firstly, the above-mentioned cleaning solution was added into the cleaning tank, the temperature was raised to 50° C., the glass substrate was placed in the cleaning solution, immersed for 30 minutes, and left to stand. Next, immerse the cleaned glass panel in deionized water at 25° C. for 3 minutes, then take out the panel, repeat the same operation, and finally dry it with an air knife.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com