New environment-friendly lead-free silicon-containing alloy material and preparation method thereof

A silicon alloy and new material technology, applied in the field of alloy rods, can solve the problems of difficult processing, high cost, hot brittleness, etc., and achieve the effects of improving mechanical properties, improving environmental performance and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

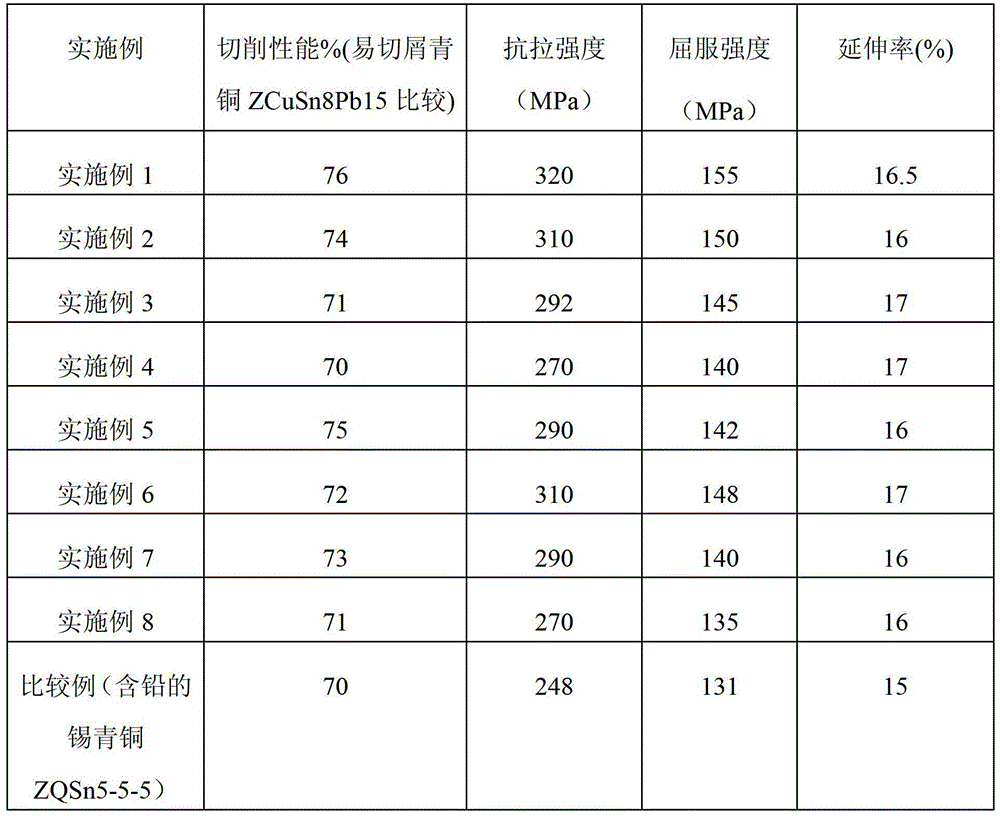

Examples

Embodiment 1

[0028] A new environment-friendly lead-free silicon-containing alloy material comprises the following components in percentage by weight: 6%-8% zinc, 6%-8% tin, 1%-3% silicon, and the balance copper. The preparation method is as follows: put each component in a power frequency electric furnace according to the proportion, heat it to 1250-1300 degrees and completely melt it, then keep it warm to 1200 degrees; stir the completely melted alloy liquid with a graphite rod, and put it on it Cover the high-purity scaly graphite powder with a thickness of about 11cm-13cm to prevent its oxidation; after 1.2-1.5 hours of heat preservation, use a direct-reading spectrometer to test the composition of the sample taken out of the furnace 3-5 times to determine its alloy composition Within the specified range; after further heat preservation for 60 minutes, the temperature was raised to 1300 degrees again, and the vibration device of the power frequency electric furnace was turned on, and a ...

Embodiment 2

[0031] A new environment-friendly lead-free silicon-containing alloy material is composed of the following components in weight percentage: 7% zinc, 6.8% tin, 2% silicon, and the balance copper. The preparation method is as follows: put each component in a power frequency electric furnace according to the proportion, heat it to 1300 degrees and completely melt it, then keep it warm to 1200 degrees; stir the completely melted alloy liquid with a graphite rod, and cover it with a thickness of about 12cm high-purity flaky graphite powder to prevent its oxidation; after 1.2-1.5 hours of heat preservation, use the Spike direct-reading spectrometer imported from Germany to test the composition of the sample taken out of the furnace 5 times to determine its alloy composition. Within the range; after further holding for 60 minutes, the temperature was raised to 1300 degrees again, and the vibration device of the power frequency electric furnace was turned on, and a solid alloy bar with...

Embodiment 3

[0034] A new environment-friendly lead-free silicon-containing alloy material comprises the following components in percentage by weight: 6% zinc, 6% tin, 1% silicon, and the balance copper. The preparation method is as follows: put each component in a power frequency electric furnace according to the proportion, heat it to 1250-1300 degrees and completely melt it, then keep it warm to 1200 degrees; stir the completely melted alloy liquid with a graphite rod, and put it on it Cover the high-purity scaly graphite powder with a thickness of about 11cm-13cm to prevent its oxidation; after 1.2-1.5 hours of heat preservation, use a direct-reading spectrometer to test the composition of the sample taken out of the furnace 3-5 times to determine its alloy composition Within the specified range; after further heat preservation for 60 minutes, the temperature was raised to 1300 degrees again, and the vibration device of the power frequency electric furnace was turned on, and a solid all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com