Composited sodium alga acid antibacterial film and application thereof in preservation of livestock meat carcass

A sodium alginate and compound antibacterial technology, which is applied in the direction of preserving meat/fish with chemicals and preserving meat/fish with a protective coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: In this embodiment, sodium alginate is used as the film-forming base material, sodium carboxymethyl cellulose is the raw material of the blended film, and plasticizer glycerin and preservative potassium sorbate are added, and the transparency of the film is measured , thickness, mechanical properties and other indicators, the optimal composition of the composite antibacterial film is determined as:

[0020] (1) Sodium alginate film-forming solution:

[0021] ① Determination of the concentration of sodium alginate: Dissolve 1, 2, 3, 4, and 5 g of sodium alginate in distilled water, and stir with an electric stirrer in a water bath at 60°C until fully swollen to make a concentration of 0.5 g / mL and 1 g / mL, 1.5g / mL, 2g / mL, 2.5g / mL film-forming solution, according to the thickness of the film, transparency, water absorption, water vapor transmission coefficient, tensile strength, elongation at break and other indicators, screening The most suitabl...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in the composite film-forming solution of sodium alginate and sodium carboxymethyl cellulose, the sodium alginate film-forming solution and sodium carboxymethyl cellulose solution The volume ratios are 10:0, 9:1, 8:2, 7:3, 6:4, 5:5, respectively.

specific Embodiment approach 3

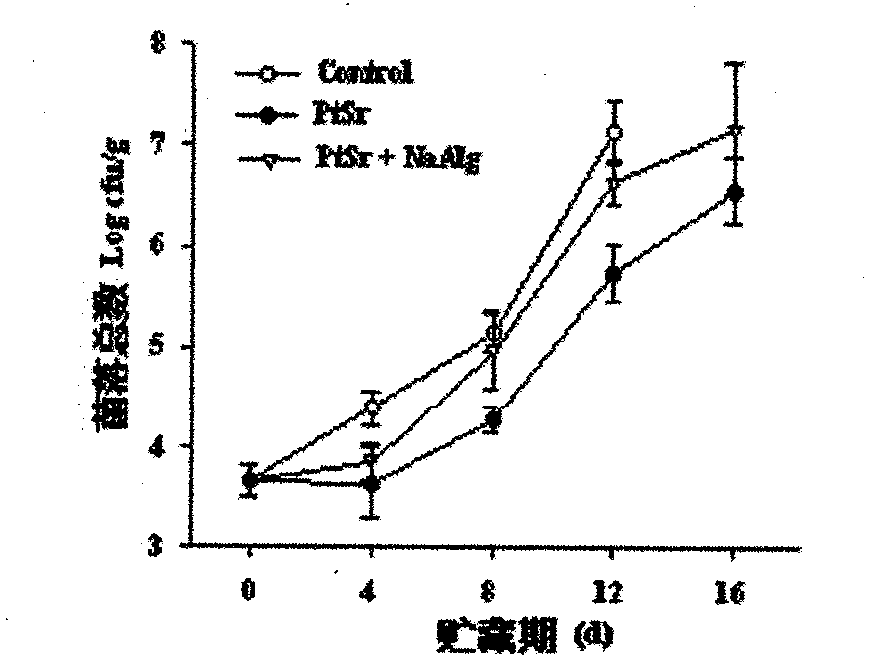

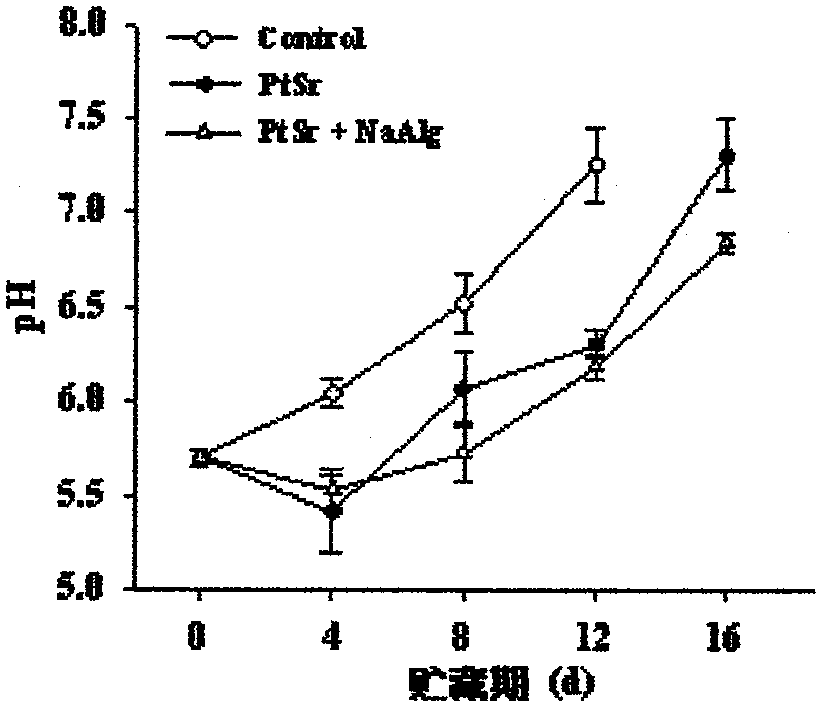

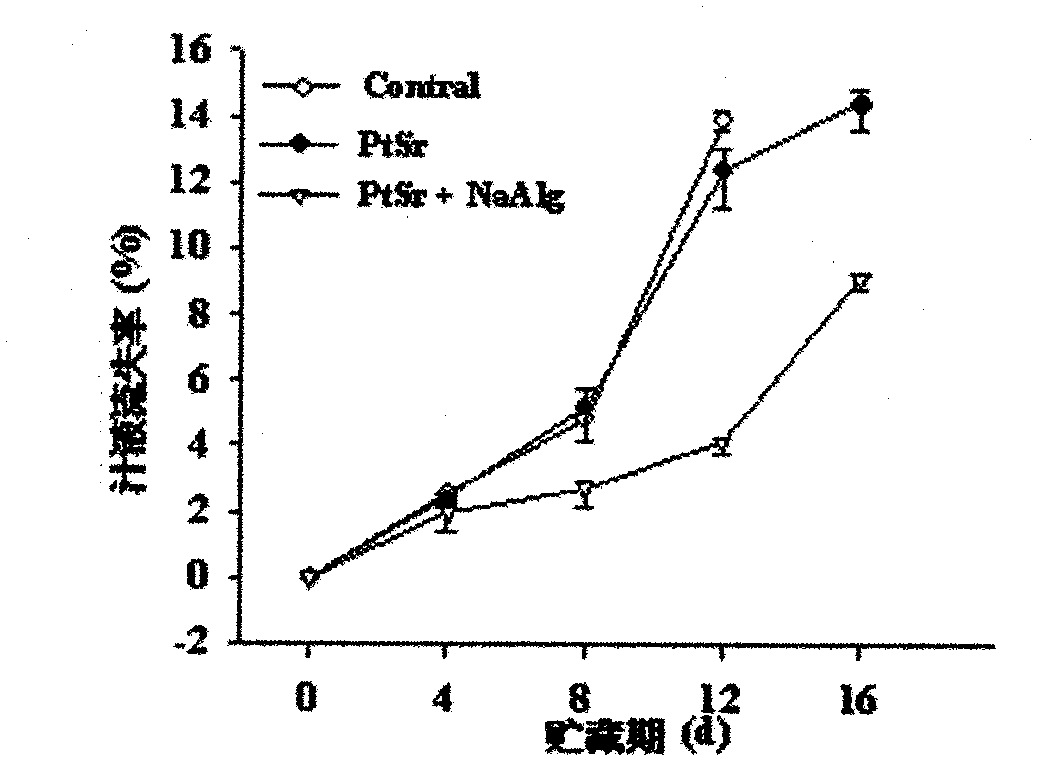

[0029] Specific Embodiment Three: In this embodiment, the technical solution of the present invention will be further explained in conjunction with the accompanying drawings.

[0030] 1. Preparation of sodium alginate edible film

[0031] 1. Effect of sodium alginate concentration on membrane properties

[0032] Table 1 Effect of sodium alginate concentration on membrane properties

[0033]

[0034] It can be seen from Table 1 that as the concentration of sodium alginate film-forming solution increases, the thickness of the film increases continuously, and the light transmittance of the film decreases continuously, and the difference is significant (p<0.05). When the concentration of the sodium alginate film-forming solution is 0.5g / mL, the film-forming solution is thin and the film formed after drying is thin and difficult to form a complete film, but the transparency reaches 96%. When the concentration increased to 2g / mL, the film liquid became viscous, yellow in color,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com