A moisture control method for tobacco redrying machine based on predictive pi algorithm control system

A control system and control method technology, applied in the preparation of tobacco, tobacco, application, etc., can solve the problems of unguaranteed accuracy, complicated control, abnormal equipment, etc., and achieve the goal of improving process control ability, suppressing measurement noise, and improving processing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

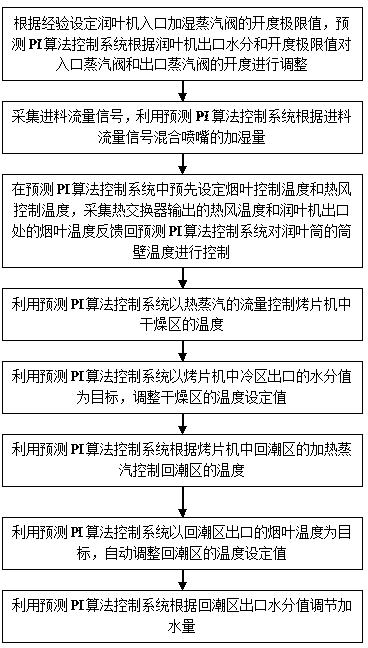

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

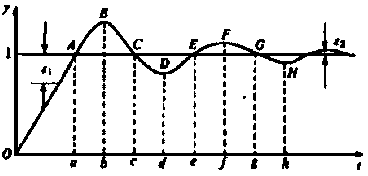

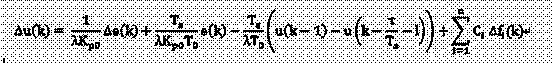

[0031] In the embodiment of the present invention, a quality control method for the rebaking process with upstream and downstream linkages is mainly established in the two key process sections of moistening leaves and baking slices. In this embodiment, the advanced control of moisture in the hot air moistening section is used as the first tobacco leaf moisture and temperature control link in threshing and redrying. The anti-breakage performance of tobacco leaves plays a major role in a large amount of processing, and the stable outlet moisture of moistening leaves creates conditions for improving the moisture accuracy of re-baking. Secondly, carry out advanced control of moisture in the rebaking section, realize precise control of the temperature zone in the drying area, create basic conditions for characteristic rebaking, tru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com