Nano manganese oxide composite material as well as preparation method and application thereof in anion pollutant processing

A composite material and oxide technology, used in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problems of low zero charge point of manganese oxide and difficulty in efficiently removing anionic pollutants. , to improve the application performance, the adsorption performance will not decline, and the pressure drop will be reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

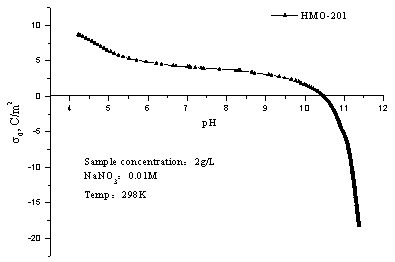

[0026] In this example 1, the nano-manganese oxide composite material HMO-201 was obtained by using strongly basic anion exchange resin D201 to immobilize hydrated manganese oxide particles, with an average particle size of 0.8 mm and a specific surface area of 10 m 2 / g, pore volume 0.05 cm 3 / g, the manganese loading is 20%, and the zero charge point is 10.5; the particle size of the hydrated manganese oxide loaded is 20nm, and the crystal form is amorphous.

[0027] The specific preparation steps of the above-mentioned nano-manganese oxide composite material are as follows:

[0028] (1) 1.58g KMnO 4 Dissolve in 200mL water to obtain solution A, in which MnO 4 - The concentration is 0.05M;

[0029] (2) The mixture of 150mL absolute ethanol and 50mL water is solution B;

[0030] (3) Weigh 10g of D201 resin into a three-necked flask, add solution A to it, and stir at 500r / min for 10h at 25°C to make MnO 4 - Fully exchanged to the surface and interior of the resin;

[...

Embodiment 2

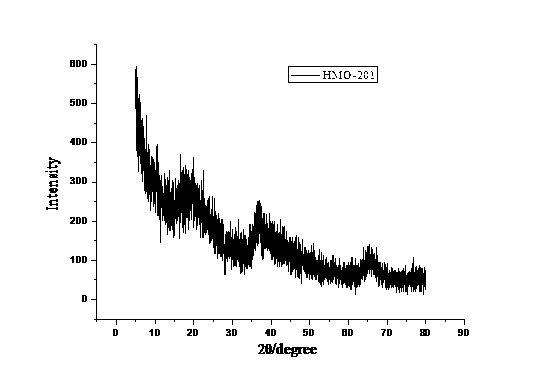

[0035] In Example 2, the nano-manganese oxide composite material HMO-201 was obtained by using strongly basic anion exchange resin D201 to immobilize hydrated manganese oxide particles, with an average particle size of 0.5 mm and a specific surface area of 5 m 2 / g, pore volume 0.05cm 3 / g, manganese load 20%, zero charge point is 10.96; the particle size of hydrated manganese oxide loaded is 2nm, and the crystal form is amorphous (such as image 3 shown).

[0036] The specific preparation steps of the above-mentioned nano-manganese oxide composite material are as follows:

[0037] (1) Add 0.158g KMnO 4 Dissolve in 100mL water to obtain solution A, in which MnO 4 - The concentration is 0.01M;

[0038] (2) The mixture of 25mL propanol and 25mL water is solution B;

[0039] (3) Weigh 10g of D201 resin into a three-necked flask, add solution A to it, and stir at 300r / min for 10h at 5°C to make MnO 4 - Fully exchanged to the surface and interior of the resin;

[0040] ...

Embodiment 3

[0044] In Example 3, the nano-manganese oxide composite material HMO-201 was obtained by using strongly basic anion exchange resin D201 to immobilize hydrated manganese oxide particles, with an average particle size of 1.5 mm and a specific surface area of 30 m 2 / g, pore volume 0.005cm 3 / g, the manganese load is 40%, and the zero charge point is 10.6; the particle size of the hydrated manganese oxide loaded is 50nm, and the crystal form is amorphous.

[0045] The specific preparation steps of the above-mentioned nano-manganese oxide composite material are as follows:

[0046] (1) 14.22g KMnO 4 Dissolve in 300mL water to obtain solution A, in which MnO 4 - The concentration is 0.3M;

[0047] (2) The mixture of 100mL absolute ethanol and 10mL water is solution B;

[0048] (3) Weigh 10g of D201 resin into a three-necked flask, add solution A to it, and stir at 600r / min for 16h at 5°C to make MnO 4 - Fully exchanged to the surface and interior of the resin;

[0049] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com