Device and method for laser etching of conducting film layers on touch on lens (TOL) and one glass solution (OGS) touch components

A conductive film layer, laser etching technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of limited application field, large initial investment, increased labor cost and production cost, etc., to achieve linear stability, functional Complete, simple processing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

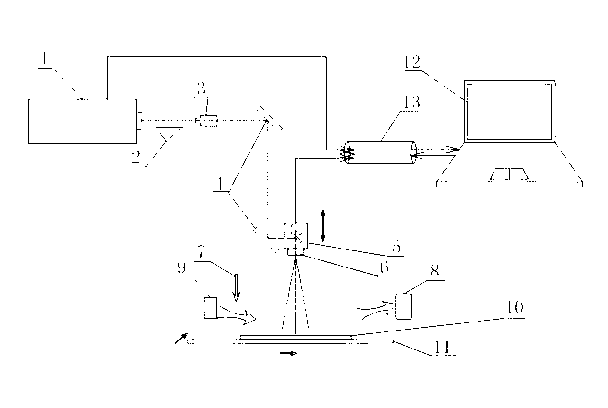

[0020] like figure 1 As shown, the device used for laser etching of the conductive film layer on TOL and OGS touch includes a laser 1, a shutter 2, a beam expander 3, a full-reflection lens group 4, a vibrating mirror system 5, and a telecentric field mirror 6 , the laser 1 is a laser with a wavelength of 199nm to 1064nm, a pulse width of 1ps to 500ns, and a frequency of 1KHz to 2MKHz. The output end of the beam mirror 3 is arranged with a full reflection mirror group 4, and the output end of the full reflection mirror group 4 is arranged with a galvanometer system 5 and a telecentric field mirror 6 in turn, and the output end of the telecentric field mirror 6 is facing the vacuum adsorption platform 11, A CCD alignment observation system 7 is arranged above the vacuum adsorption platform 11, an air blowing system 9 is arranged on one side of the vacuum adsorption platform 13, and a dust collection system 8 is installed on the other side; the laser 1 and the vibrating mirror s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com