Scaling flux for soldering

A flux and soldering technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of poor electrical insulation performance, insufficient welding activity, cleaning, etc., and achieve high surface insulation resistance, Good solderability and high cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

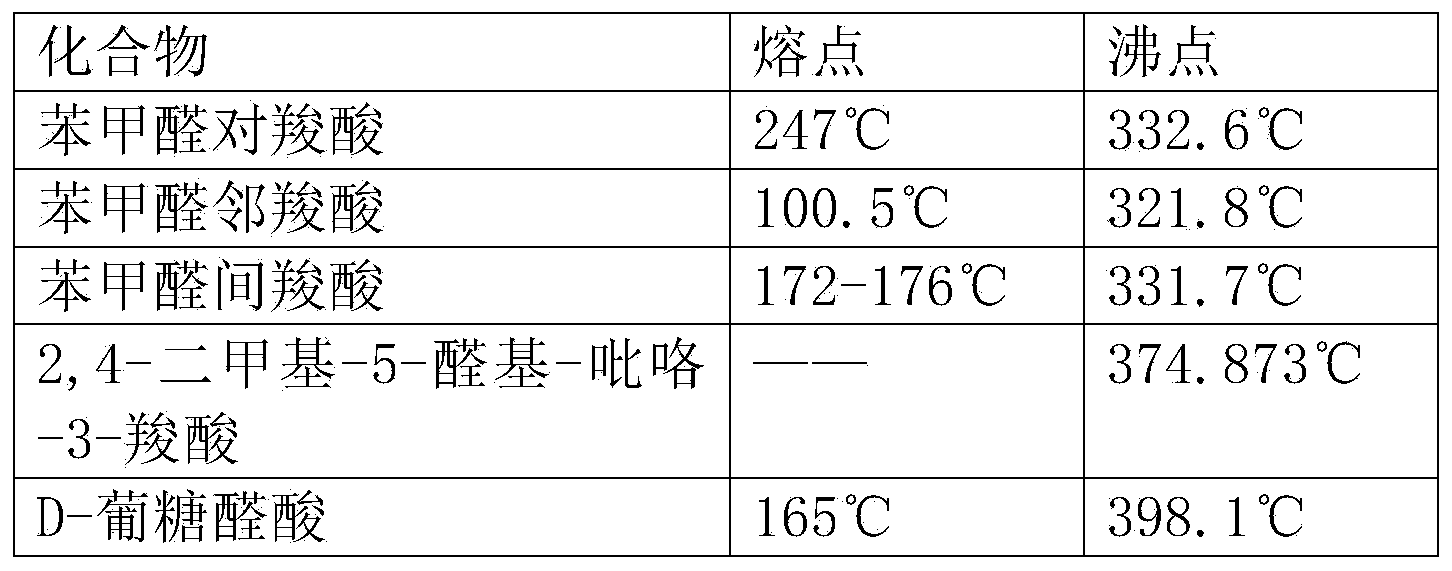

Image

Examples

Embodiment 1

[0044] Embodiment 1, a kind of soldering flux, is made of the following raw materials in parts by weight:

[0045] Element

parts by weight

Isopropanol

98

Organic solvents

1.5

Organic dicarboxylic acid active agent

0.2

Organic dicarboxylic acid active agent

Benzaldehyde o-carboxylic acid

0.2

Organic aldehyde acid compound

OP-10

0.1

Surfactant

[0046] Preparation of soldering flux:

[0047] 1. Weigh the raw materials according to the parts by weight of the above raw materials, add the organic solvent and the solubilizing wetting agent into the stirring vessel, and then add the paste or solid organic carboxylic acid active agent and organic aldehyde acid in order according to the parts by weight. compounds and surfactants.

[0048] 2. Stir the above raw materials for 20-40 minutes at a temperature of 20-60°C, so that the pasty or solid raw materials ...

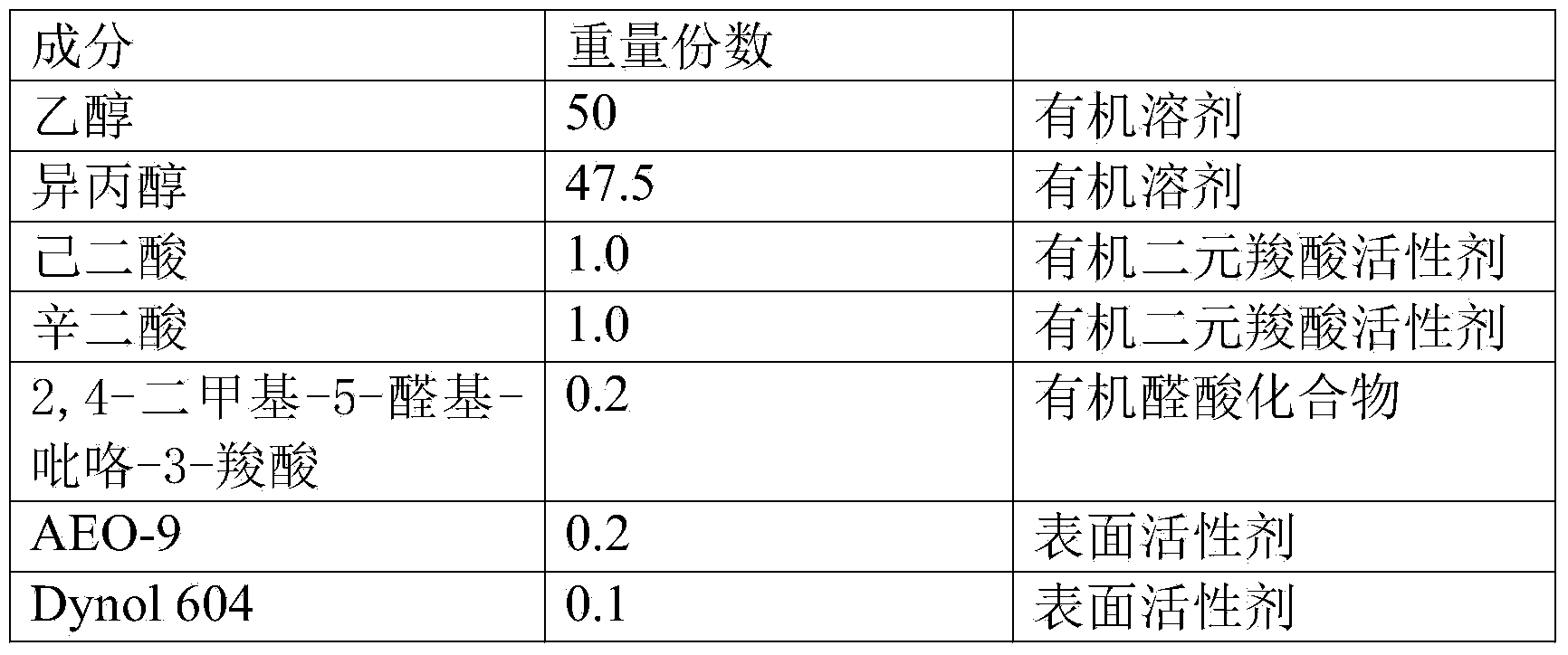

Embodiment 2

[0051] Embodiment 2, a kind of soldering flux, is made of the following raw materials in parts by weight:

[0052]

[0053] The preparation method of the soldering flux of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

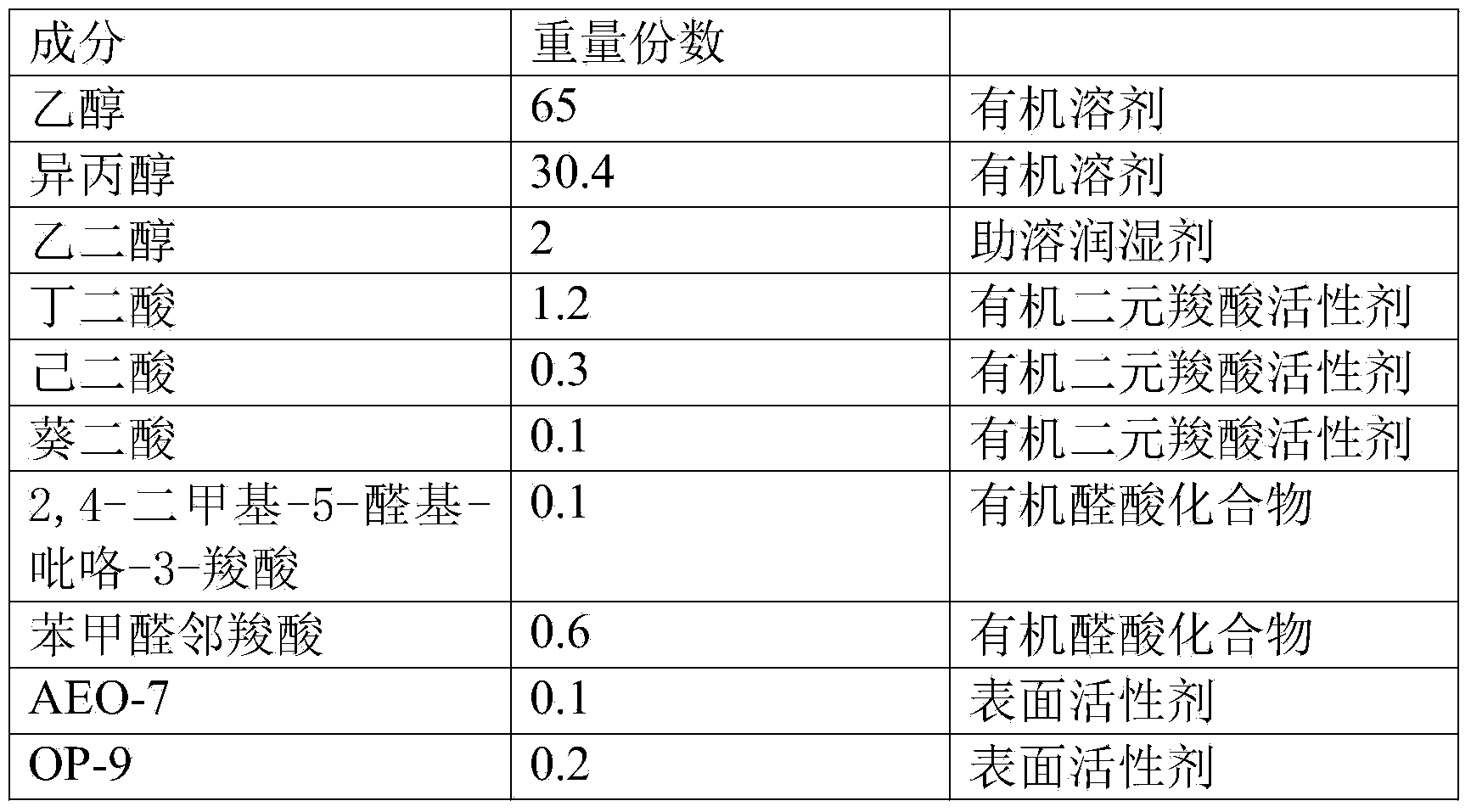

Embodiment 3

[0054] Embodiment 3, a kind of soldering flux, is made of the following raw materials in parts by weight:

[0055] Element

[0056] glutaric acid

[0057] The preparation method of the soldering flux of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com