Aqueous polyurethane emulsion as well as application thereof on electrophoretic display coating liquid and display device

A water-based polyurethane, electrophoretic display technology, used in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, coatings, etc. The effect of improving tensile strength and cohesion, good adhesion and film strength, and improving volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

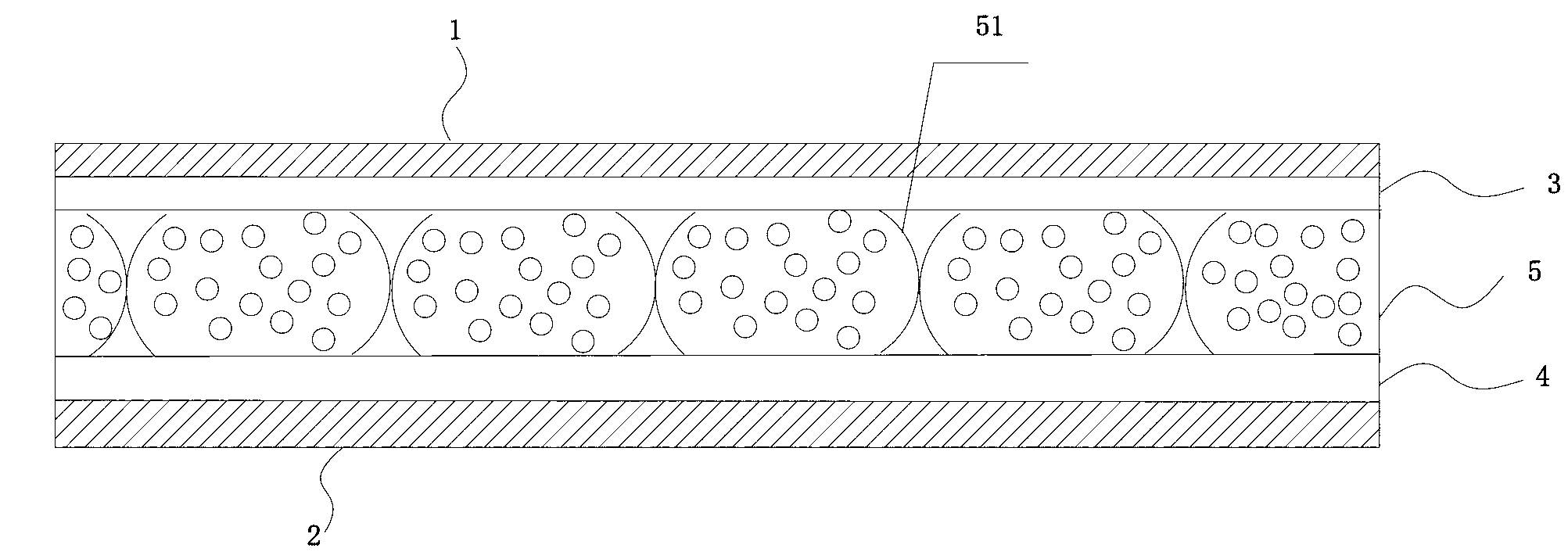

Image

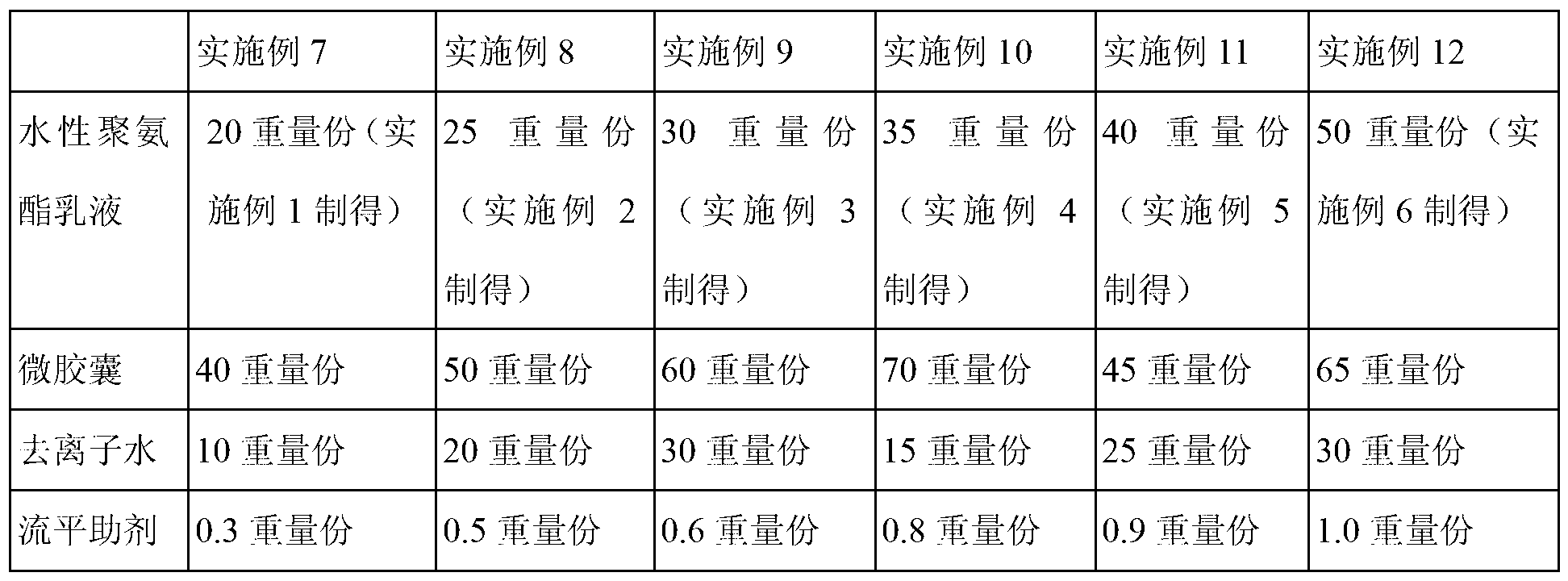

Examples

Embodiment 1

[0037] An aqueous polyurethane emulsion is prepared according to the following preparation steps:

[0038] 1) Weigh the first part of the raw materials, that is, weigh 18 polyester diols, 40 polyether diols (number average molecular weight Mn is 500), 13 polyethylene glycols, and 3 small molecules by weight. The dihydric alcohol chain extender and the diisocyanate of 26 were put into the reaction pot and stirred at 85°C for 4 hours to form the reaction mixture I;

[0039] 2) When the reaction mixture I in step 1) becomes viscous, add the low-boiling solvent acetone of the second part of the raw material, the amount of which is 1-1.2:2 compared with the total weight of the first part of the raw material, and lower the temperature to 50°C, Stir until the reaction mixture I is completely dissolved to form the reaction mixture II; the method for judging that the reaction mixture I becomes viscous is to prepare a 50% DMF (N,N-dimethylformamide) solution of the reaction mixture I, 2...

Embodiment 2

[0043] An aqueous polyurethane emulsion is prepared according to the following preparation steps:

[0044] 1) Weigh the first part of the raw materials, that is, weigh 20 polyester diols, 48 polyether diols (number average molecular weight Mn is 800), 15 polyethylene glycols, and 6 small molecules by weight. Polyamine chain extender and 23 diisocyanate, put them into the reaction pot, and stir at 85 ° C for 5 hours to form reaction mixture I;

[0045] 2) When the reaction mixture I in step 1) becomes viscous, add the second part of the raw material low-boiling solvent butanone in an amount of 1.4:2 compared to the total weight of the first part of the raw material, lower the temperature to 58°C, and stir. Until the reaction mixture I is completely dissolved, the reaction mixture II is formed; the method for judging that the reaction mixture I becomes viscous is to prepare a 50% DMF solution of the reaction mixture I. At 25°C, the measured viscosity is greater than 50,000 mPa...

Embodiment 3

[0049] An aqueous polyurethane emulsion is prepared according to the following preparation steps:

[0050] 1) Weigh the first part of the raw materials, that is, weigh 9 polyester diols, 36 polyether diols (number average molecular weight Mn is 1000), 10 polyethylene glycols, and 2 small molecules by weight. Polyol chain extender and 20% aliphatic diisocyanate, put them into the reaction pot, and stir at 70°C for 2 hours to form reaction mixture I;

[0051] 2) When the reaction mixture I in step 1) becomes viscous, add the low-boiling solvent acetone of the second part of the raw material, the amount of which is 1:2 compared with the total weight of the first part of the raw material, lower the temperature to 45°C, and stir until The reaction mixture I is completely dissolved to form the reaction mixture II; the method for judging that the reaction mixture I becomes viscous is to prepare a 50% DMF solution of the reaction mixture I, and the measured viscosity is greater than 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com