High-strength and flame-retardation thermoplastic composite material for subway tunnel platform, and preparation method of composite sheet thereof

A composite material and thermoplastic technology, applied in the field of polymer materials, can solve the problems of non-recyclable thermosetting composite materials, poor control of formaldehyde content, low molecular formaldehyde volatilization, etc., and achieve the effect of light weight, easy replacement, and fire protection safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

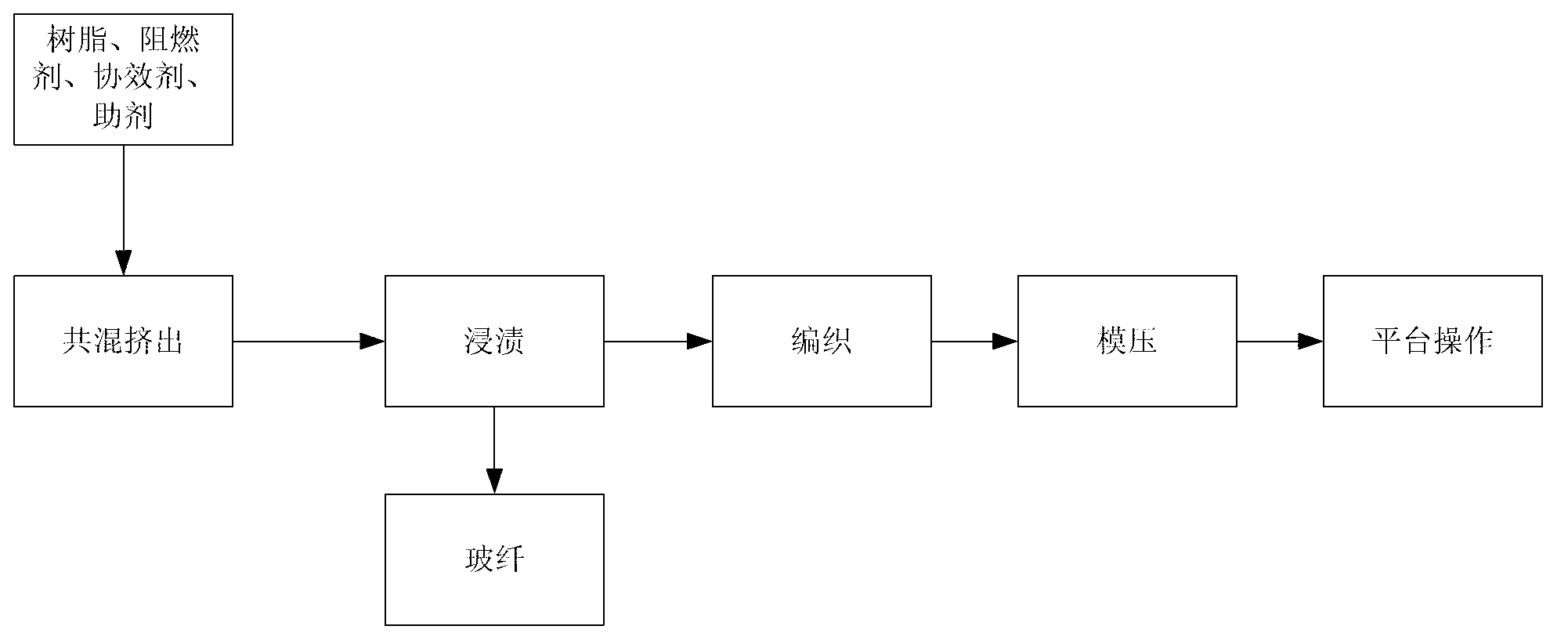

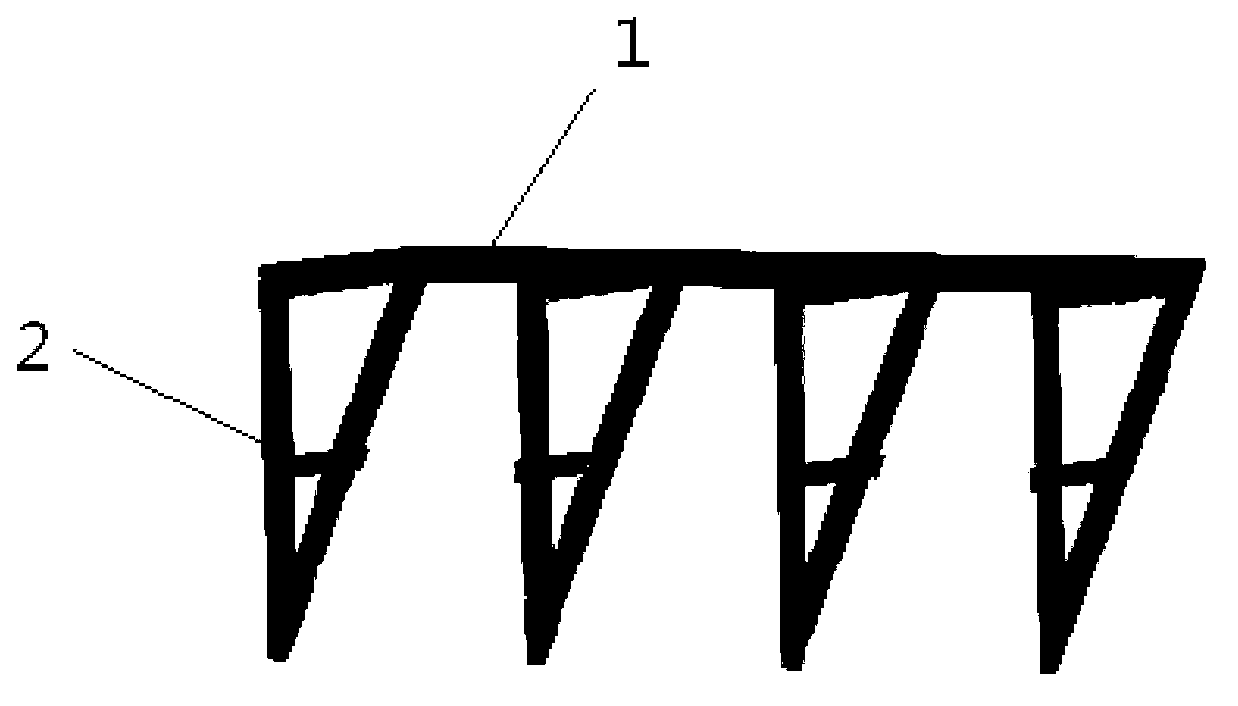

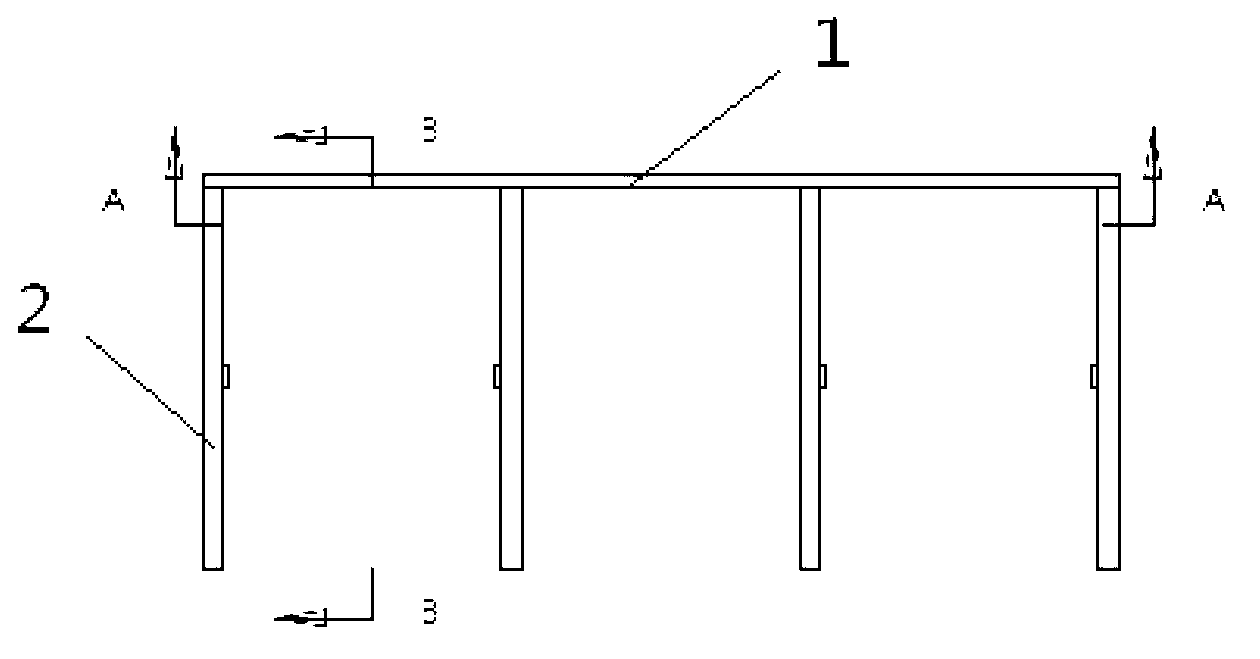

[0053] Composite material of the present invention and sheet material preparation method thereof, such as figure 1 shown, including:

[0054] Using a twin-screw extruder to melt and blend the component A in claim 1 according to the ratio of raw materials and extrude it to the dipping die;

[0055] Continuously feeding the glass fiber of component B according to claim 1 into the impregnation die, impregnating and coating the melt formed by component A, to form a flame-retardant reinforced thermoplastic composite material;

[0056] The composite material is continuously drawn to obtain a composite material flat strip;

[0057] warp weaving the webbing strips into a sheet;

[0058] A number of woven sheets are superimposed and hot-pressed into a sheet to obtain a flame-retardant reinforced composite sheet for the manufacture of the tunnel platform.

[0059] According to the present invention, the preparation method of the composite board is as follows: after homogeneously mixi...

Embodiment

[0065] Resin and additives such as flame retardants are homogeneously mixed and then added to a twin-screw extruder for continuous melt blending and extruding to the die head. The glass fiber is continuously fed into the die head, impregnated and coated by the melt, and reinforced by long glass fibers by traction. Flame retardant thermoplastic composite tape. Twin-screw blending extrusion temperature: 230-270°C, choose the appropriate extrusion temperature according to different base materials.

[0066] Strips are woven into sheets by a knitting machine

[0067] Overlay molding of multi-layer sheets to obtain the required sheet

[0068] Molding process conditions: temperature: 240-280°C, heating time: 2-3h, pressure: 7-10MPa, the molding temperature and pressure can be selected according to the different resins of the body and the thickness of the board.

[0069] The plate is engraved and sampled, and the mechanical properties and flame retardancy of the material are tested ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com