Preparation method of sample with standard fiber component content

A standard sample and component content technology, applied in the textile field, can solve the problem that the preparation method cannot meet the detection of fiber component ratio, etc., and achieve the effect of good molding, simple operation method and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of the standard sample of embodiment 1 polyester and cotton fiber

[0027] There are 19 content ratios of polyester and cotton fiber, which are 5 / 95, 10 / 90, 15 / 85, 20 / 80, 25 / 75, 30 / 70, 35 / 65, 40 / 60, 45 / 55, 50 / 50, 55 / 45, 60 / 40, 65 / 35, 70 / 30, 75 / 25, 80 / 20, 85 / 15, 90 / 10, 95 / 5, prepare two standard samples for each ratio.

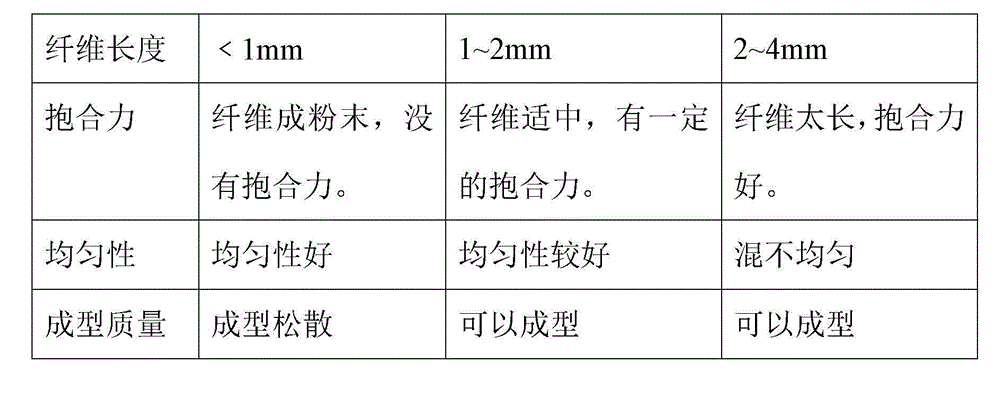

[0028] 1) Short fiberization: cut the fiber into short fibers with a length of 1~2mm;

[0029] 2) Drying: Dry the cut short fibers in an oven at 105°C until constant weight, and put them in an airtight container for later use;

[0030] 3) Weighing: Calculate the amount of polyester and cotton fibers that should be weighed according to the proportion of the planned configuration, and weigh with an infrared drying balance with a sensitivity of 0.0001g. Before weighing, you should also perform infrared drying twice Dry, so that the difference between the two weighings does not exceed 1%; put the weighed fiber in a glass container with a s...

Embodiment 2

[0037] The preparation of the standard sample of embodiment 2 wool and acrylic fiber

[0038] There are 19 content ratios of wool and acrylic fiber, which are 5 / 95, 10 / 90, 15 / 85, 20 / 80, 25 / 75, 30 / 70, 35 / 65, 40 / 60, 45 / 55, 50 / 50, 55 / 45, 60 / 40, 65 / 35, 70 / 30, 75 / 25, 80 / 20, 85 / 15, 90 / 10, 95 / 5, prepare two standard samples for each ratio.

[0039] 1) Cleaning: Wash the wool fibers in an aqueous solution of sodium dodecylbenzenesulfonate with a mass percentage of 5%, remove the grease on the wool, wash and dry;

[0040] 2) Short fiberization: cut the acrylic fiber and the washed and dried wool fiber into short fibers with a length of 1~2mm, and the cut wool fiber should be filtered in a 10-mesh sieve;

[0041] 3) Drying: Bake the filtered wool staple fiber and cut acrylic fiber in an oven at 105°C to constant weight. Make sure the sample is as dry as possible, put it in a closed container, and keep it for later use;

[0042] 4) Weighing: Calculate the amount of wool staple fiber a...

Embodiment 3

[0049] The preparation of the standard sample of embodiment 3 viscose glue and nylon fiber

[0050] A total of 19 content ratios of viscose and nylon fibers are 5 / 95, 10 / 90, 15 / 85, 20 / 80, 25 / 75, 30 / 70, 35 / 65, 40 / 60, 45 / 55, 50 / 50, 55 / 45, 60 / 40, 65 / 35, 70 / 30, 75 / 25, 80 / 20, 85 / 15, 90 / 10, 95 / 5, prepare two standard samples for each ratio.

[0051] 1) Cleaning: Wash the nylon fiber in an aqueous solution of sodium dodecylbenzenesulfonate with a mass percentage of 5%, remove the grease on the nylon fiber, wash and dry;

[0052] 2) Short fiberization: cut viscose fiber and cleaned nylon fiber into short fibers with a length of 1~2mm;

[0053] 3) Drying: Bake the cut viscose and nylon fibers in an oven at 105°C to constant weight. Make sure that the samples are as dry as possible, and put them in a closed container for later use;

[0054] 4) Weighing: Calculate the amount of viscose and nylon fibers that should be weighed according to the proportion of the planned configuration, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com