Safety rod driving system of liquid heavy metal cooling reactor

A liquid heavy metal and driving system technology, applied in the field of reactor engineering and reactor equipment, can solve the problem that the safety rod driving system cannot directly apply liquid heavy metal to cool the reactor, and achieve the effect of simple structure, high system reliability and simple working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

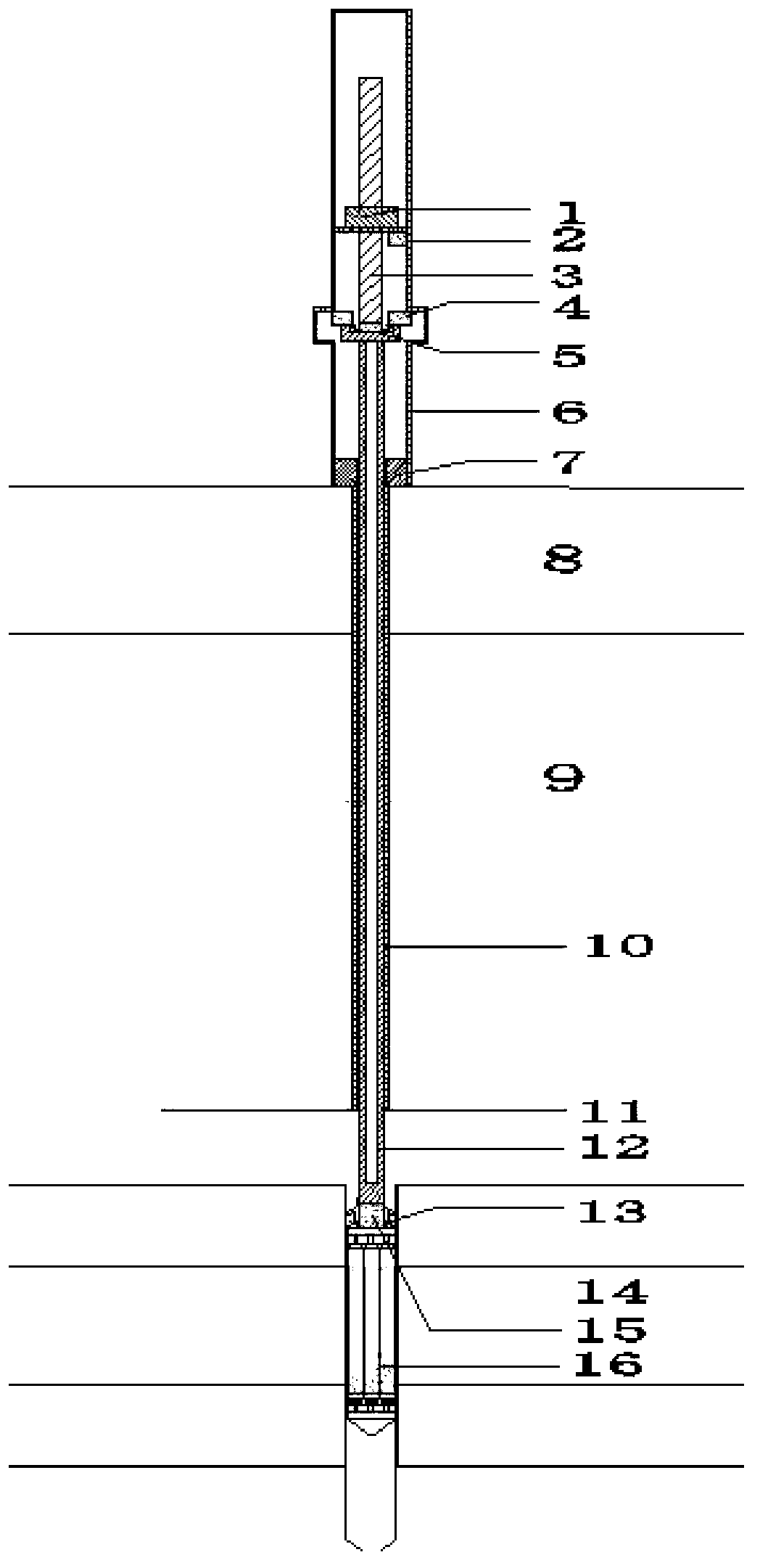

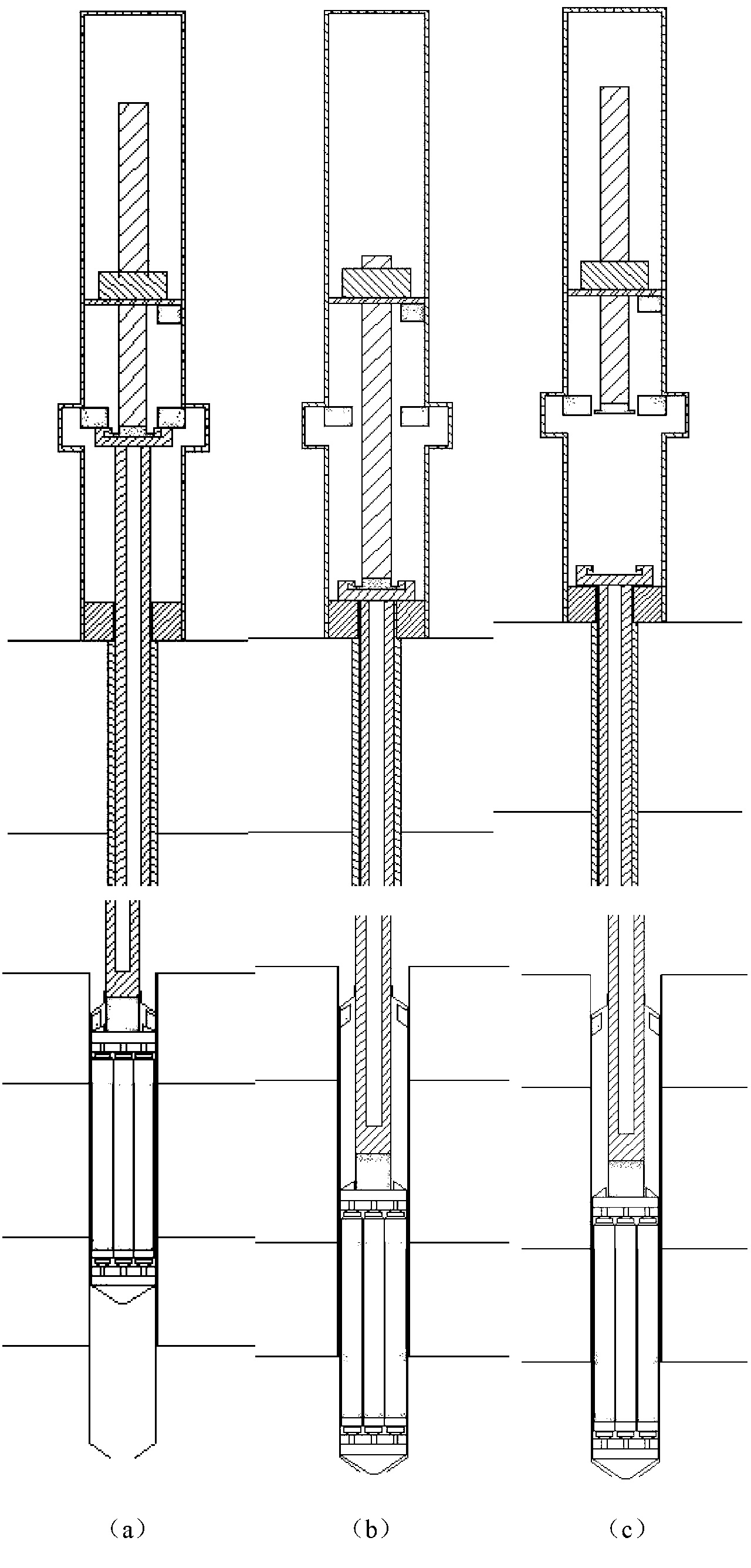

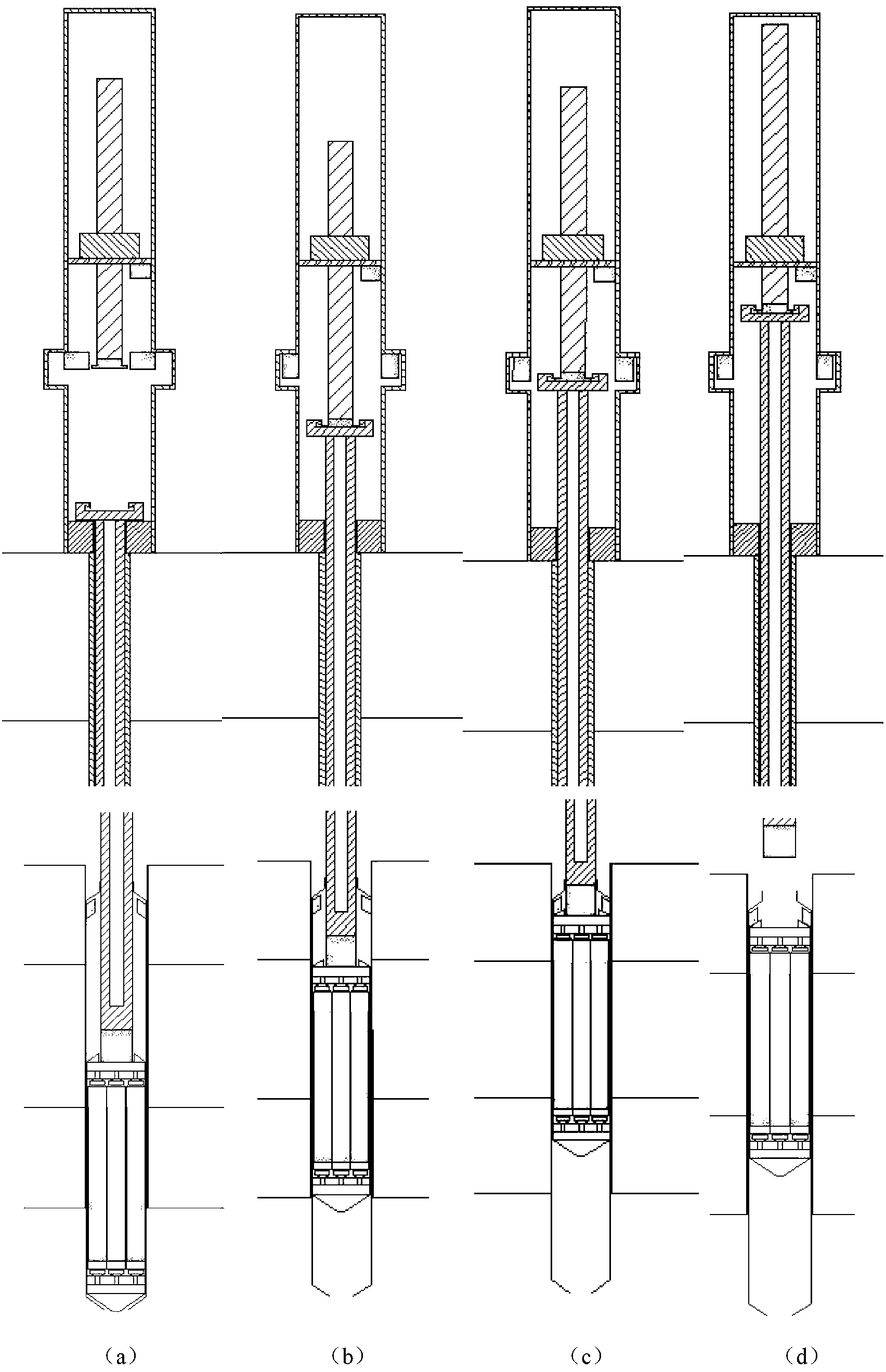

[0033] The specific structure and specific implementation methods of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] The specific working mode of the safety rod driving system of a liquid heavy metal cooling reactor of the present invention is as follows:

[0035] Stack up:

[0036] The grabbing device 5 on the transmission rod locks the travel rod 12 together, the motor 1 drives the transmission rod 3, and presses down the travel rod 12, so that the safety rod bundle 16 connected with the travel rod 12 moves downward gradually, when the safety rod bundle 16 When the effective zone of the moving rod 12 is completely below the core, the upper end of the moving rod 12 just arrives at the electromagnet 7, and the electromagnet 7 is energized, and the magnetic force generated produces a binding force on the moving rod 12, and the moving rod 12 relies on the restraint of the electromagnet 7 to overcome the buoyancy. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com