Continuous wave radio frequency four-level accelerator water cooling system and manufacturing method thereof

A technology of water-cooling system and manufacturing method, which is applied in the direction of cooling/ventilation/heating transformation, accelerators, electrical components, etc., and can solve the problem of ineffective and precise control of the temperature of the radio frequency quadruple accelerator, the cooling problem of fluctuating temperature change frequency, and the complexity of peripheral supporting equipment To achieve the effect of ensuring beam stability, ensuring smooth, stable and improved water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

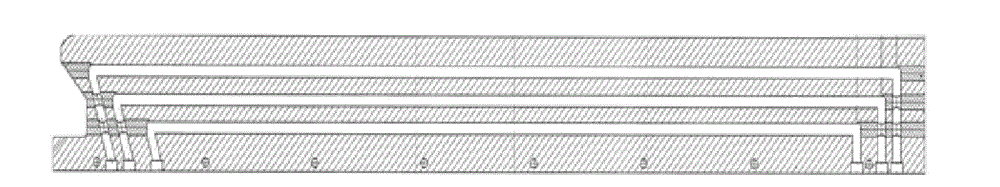

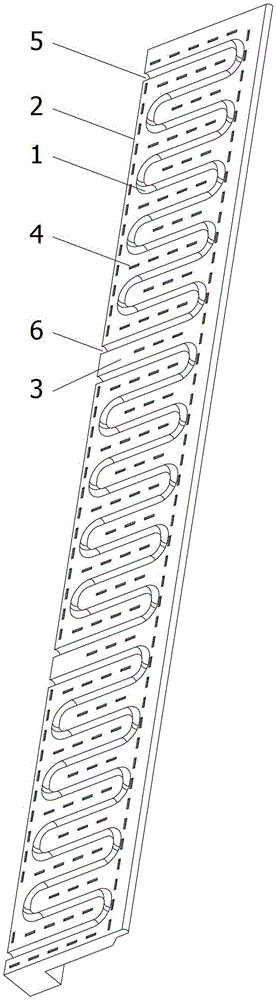

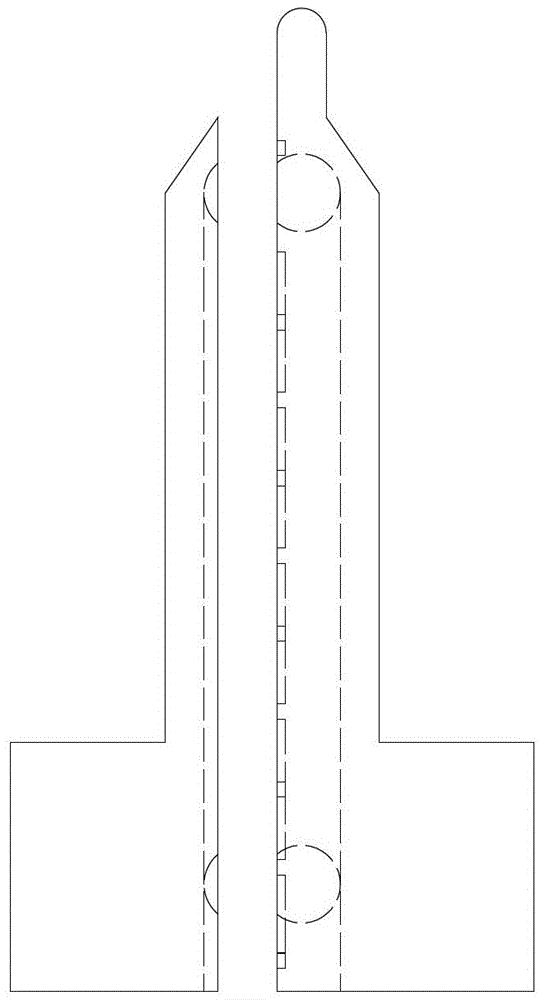

[0027] as attached figure 2 , 4 , shown in 5, a kind of continuous wave radio frequency quadruple accelerator water cooling system, is provided with water-cooling pipeline 1 in the fin as electrode, and this fin is sliced structure, and water-cooling pipeline 1 is offered at the slice 2 of fin on the docking surface 3. The water-cooling pipeline 1 is opened in a serpentine shape on the docking surface 3, and is divided into multiple sections along the length directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com