Cleaning method for fine-texture metal surface for electric discharge machining

A metal surface and electric spark technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of difficult cleaning of metal surfaces with fine textures in electric discharge machining, and achieve easy recycling, The effect of stable quality and low cleaning cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

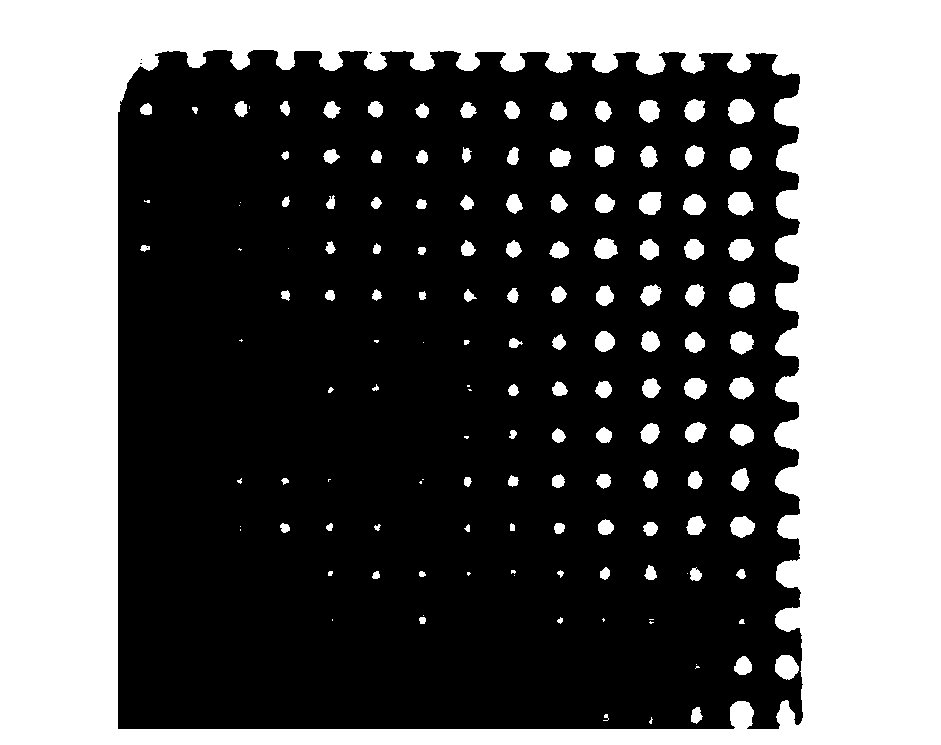

[0025] (1) The copper sheet after the surface EDM micro-machined (the surface morphology is as follows figure 1 As shown, other metals can be) immersed in kerosene, cleaned by ultrasonic vibration for 20 minutes, taken out, put in acetone solution to continue ultrasonic cleaning for 5 minutes, and then ultrasonicated in deionized water for 5 minutes, taken out and dried;

[0026] (2) The metal with micro-textured surface after ultrasonic cleaning is placed in a plasma cleaner, and cleaned with oxygen plasma for 5 minutes at a power of 18W;

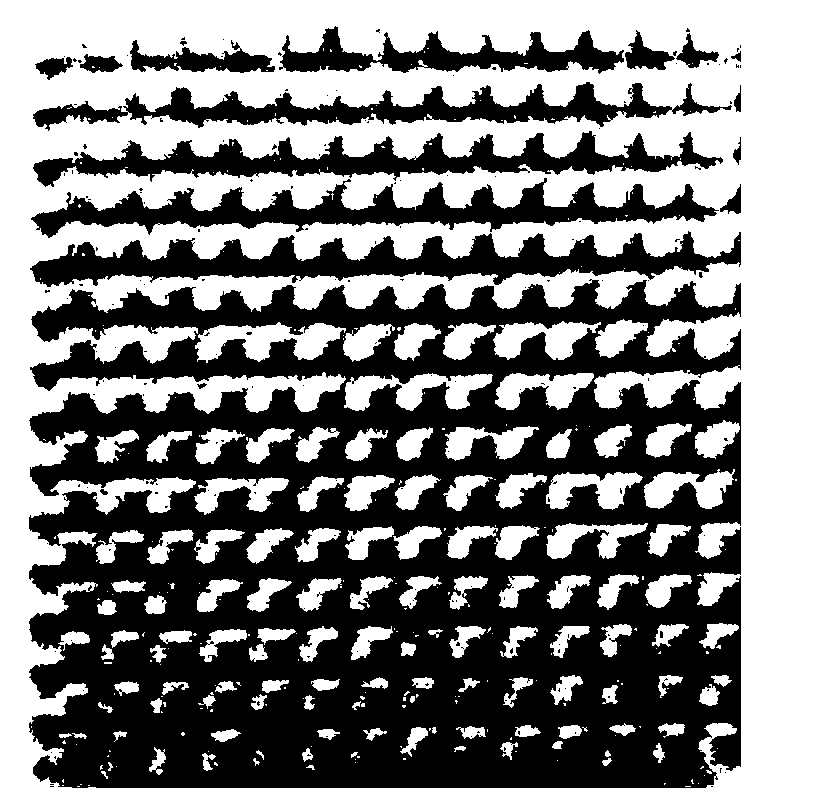

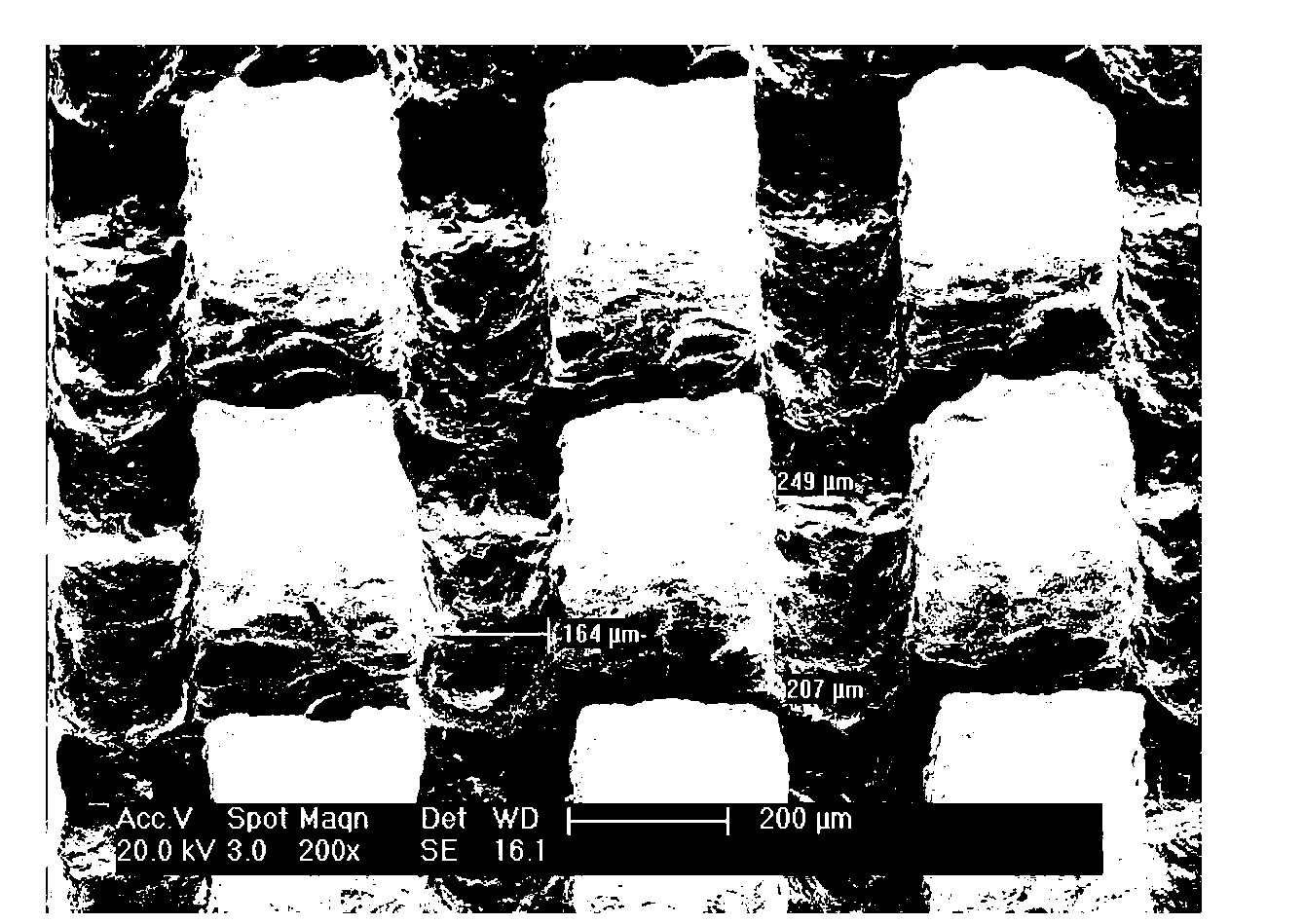

[0027] (3) Soak in 1mol / L hydrochloric acid aqueous solution for 1min, and finally rinse with deionized water, take it out and blow dry to obtain a glossy and wet metal micro-textured surface, such as figure 2 As shown, the size structure is as image 3 shown.

Embodiment 2

[0029] (1) First, immerse the surface EDM micro-processed metal in kerosene, ultrasonically clean it for 10 minutes, take it out, put it in acetone solution and continue ultrasonic cleaning for 15 minutes, then ultrasonically clean it in deionized water for 15 minutes, take it out and dry it;

[0030] (2) The metal with micro-textured surface after ultrasonic cleaning is placed in a plasma cleaning machine, and cleaned with oxygen plasma for 15 minutes at a power of 18W;

[0031] (3) Soak in 2mol / L hydrochloric acid aqueous solution for 5 minutes, and finally rinse with deionized water, take it out and blow dry to obtain a glossy and wet metal micro-textured surface.

Embodiment 3

[0033] (1) First, immerse the surface EDM micro-machined metal in kerosene, ultrasonically clean it for 13 minutes, take it out, put it in acetone solution and continue ultrasonic cleaning for 8 minutes, then ultrasonically clean it in deionized water for 10 minutes, take it out and dry it;

[0034] (2) The metal with micro-textured surface after ultrasonic cleaning is placed in a plasma cleaner, and cleaned with oxygen plasma for 12 minutes at a power of 18W;

[0035] (3) Soak in 1.8mol / L hydrochloric acid aqueous solution for 4 minutes, and finally rinse with deionized water, take it out and blow dry to obtain a shiny and wet metal micro-textured surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com