Prestressed laminated wood with creep resistant deformation performance, and preparation method and use thereof

A technology of deformation performance and glued wood, which is applied in the direction of wood layered products, wooden veneer joints, chemical instruments and methods, etc., to achieve the effects of saving wood, improving structural performance, and reducing cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

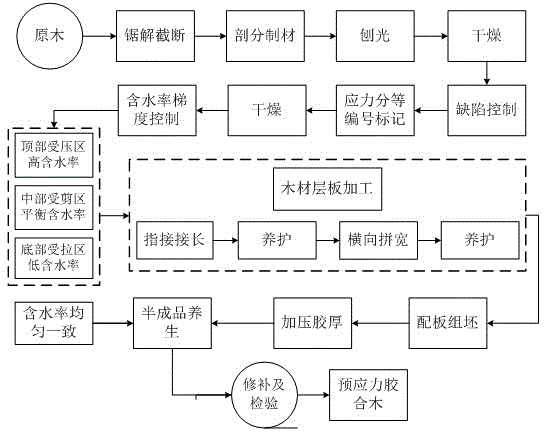

Method used

Image

Examples

Embodiment 1

[0040] Table 1 Mechanical elastic modulus graded laminate strength performance index (Mpa)

[0041] Grading ME7 ME8 ME9 ME10 ME11 ME12 ME14 ME16 ME18 Average flexural modulus of elasticity 7000 8000 9000 10000 11000 12000 14000 16000 18000

[0042] Table 2 Correspondence between mechanical stress graded laminate grades and mechanical elastic modulus graded laminate grades

[0043] Mechanical Elastic Modulus Grading ME8 ME9 ME10 ME11 ME12 ME14 mechanical stress rating M10 M14 M22 M26 M30 M40

[0044] Then carry out anti-corrosion and anti-insect or flame-retardant chemical impregnation modification treatment on the standard timber; and then control the moisture content gradient by artificial drying, and adjust the moisture content of Douglas fir wood in the top compression zone and bottom tension zone to 14% and 14% respectively. 6%, and the moisture content of fast-growing poplar wood in the ce...

Embodiment 2

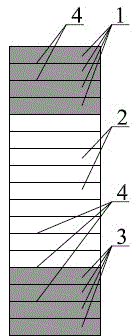

[0052] (3) Thickness and pressurization of laminates after finger jointing and widening: In the stacking thickness of laminates, they are configured according to the requirements of compression, shear and tension laminates, and the moisture content is controlled at 8% and 15% respectively. % Douglas fir laminates are arranged on the outside (bottom and top) of the glulam, masson pine laminates with a moisture content of 12% are arranged in the middle of the glulam, and the billets and gluing are maintained at the bottom tension zone. The moisture content was operated under constant environmental conditions of 8%, 15% moisture content of the wood laminate in the top compression zone and 12% moisture content of the wood laminate in the middle shear zone. Finally, pressurize under the environmental conditions of temperature 18°C-22°C and relative humidity 60%-70%, and the amount of glue applied in stacking and pressing is 150g / m 2 , the pressing pressure is 0.6MPa, the pressing t...

Embodiment 3

[0058] (3) Thickness and compression of laminates after finger-joining and widening: In the stacking thickness of the laminates, the laminates are arranged according to compression, shear and tension, and high-stress structural materials are arranged in glulam outside of the beam. Preform formation and gluing are all operated under the environmental conditions to maintain constant moisture content. Finally, pressurize under the environmental conditions of temperature 18°C-22°C and relative humidity 60%-70%, and the amount of glue applied in stacking and pressing is 300g / m 2 , the pressurization pressure is 1.2MPa, and the pressurization time is 6.0h to make a semi-finished product;

[0059] (4) Curing of semi-finished products: keep the glued wood beams under the environmental conditions of temperature 18°C-22°C and relative humidity 60%-70% until the adhesive is completely cured, and the moisture content of the wood inside the final component tends to be consistent, reaching...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com