Low-energy-consumption processing device for self-circulation sewage

A sewage treatment device and technology for treatment devices, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Day and night, seasonal changes, unstable technical operation, etc., to achieve the effect of strong resistance to hydraulic load shocks, low infrastructure operating costs, and low infrastructure and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

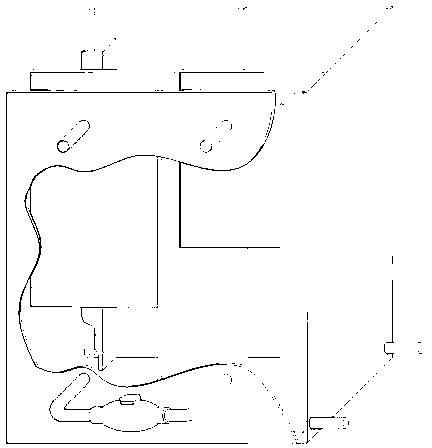

[0035] Such as figure 1 As shown, the sewage treatment device according to the present invention adopts the biofilter method of aerobic attachment, so that microorganisms aerobically attach to the surface of the filter material to form a biofilm, and absorb and degrade organic matter to achieve the purpose of purification. Different from other biological contact oxidation methods, the method of the present invention is to mix and dilute the influent and filtrate, and the treated sewage is continuously circulated and filtered inside the device, and is in constant contact with the biofilm, so as to achieve the purpose of purification. The process is very simple without the need for personnel to supervise. It is a fully automatic sewage treatment system, and the only power is the submersible pump located in the water inlet tank.

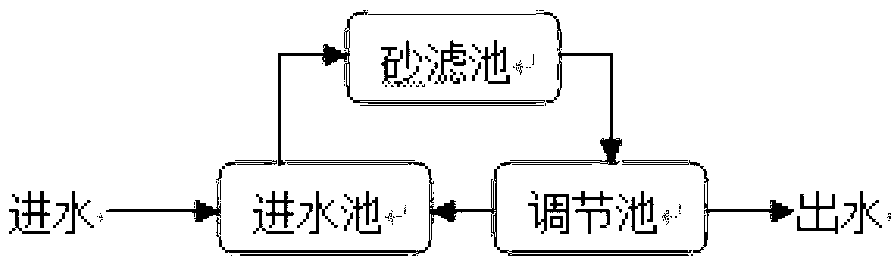

[0036] figure 2 The main components and flow of the present invention are shown. Main process: The sewage to be treated enters the water inlet tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com