Treatment process of refractory pharmaceutical park tail water

A refractory, industrial park technology, applied in water/sewage multi-stage treatment, adsorbed water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of refractory degradation, poor biodegradability of organic pollutants, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

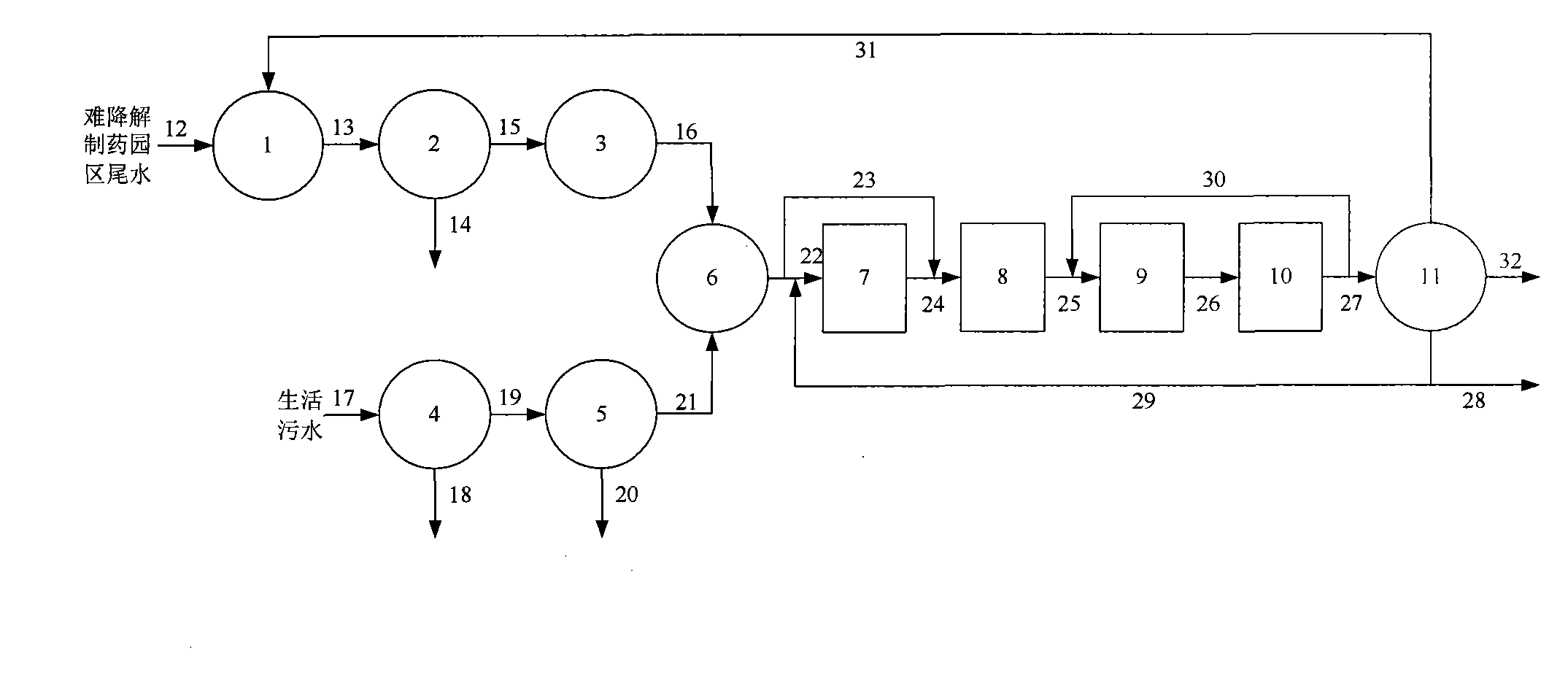

[0010] The whole flow process diagram of the advanced treatment of tail water in the refractory pharmaceutical park of the present invention is shown in Figure 1. Sand tank 4, primary sedimentation tank 5, regulating tank 6, pre-anoxic tank 7, anaerobic tank 8, anoxic tank 9, aerobic tank 10, secondary sedimentation tank 11, sludge adsorption tank inlet pipe 12, sludge adsorption Pool outlet pipe 13, sludge adsorption tank sludge discharge pipe 14, sludge adsorption tank outlet pipe 15, ozone oxidation tank outlet pipe 16, grit chamber inlet pipe 17, grit chamber sand discharge pipe 18, grit chamber outlet pipe 19 , primary sedimentation tank mud discharge pipe 20, primary sedimentation tank outlet pipe 21, pre-anoxic tank inlet pipe 22, anaerobic tank inlet pipe 23, pre-anoxic tank outlet pipe 24, anaerobic tank outlet pipe 25, anoxic tank outlet Water pipe 26, aerobic tank outlet pipe 27, secondary settling tank mud discharge pipe 28, sludge return pipe 29, nitrifying liquid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap