Preparation method of pt/ito electrode for high-efficiency electrocatalytic oxidation of ammonia

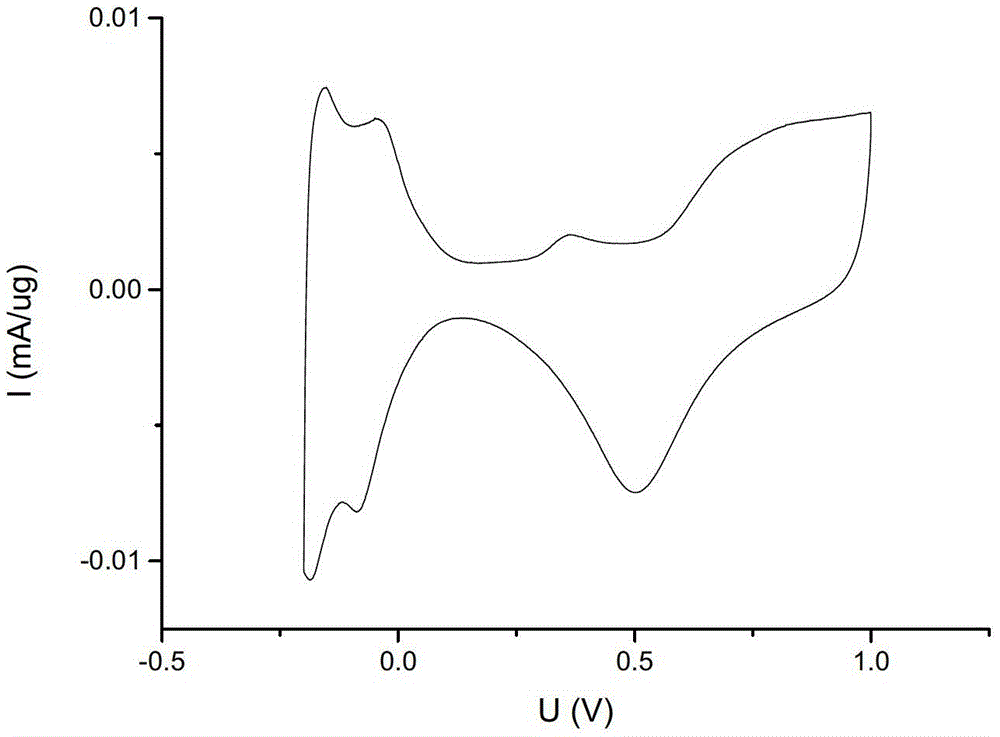

An electrocatalytic oxidation and electrode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of high manufacturing cost of Pt/ITO electrodes, unusable Pt, low utilization rate of Pt, etc., and achieve easy operation and improved utilization rate, improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

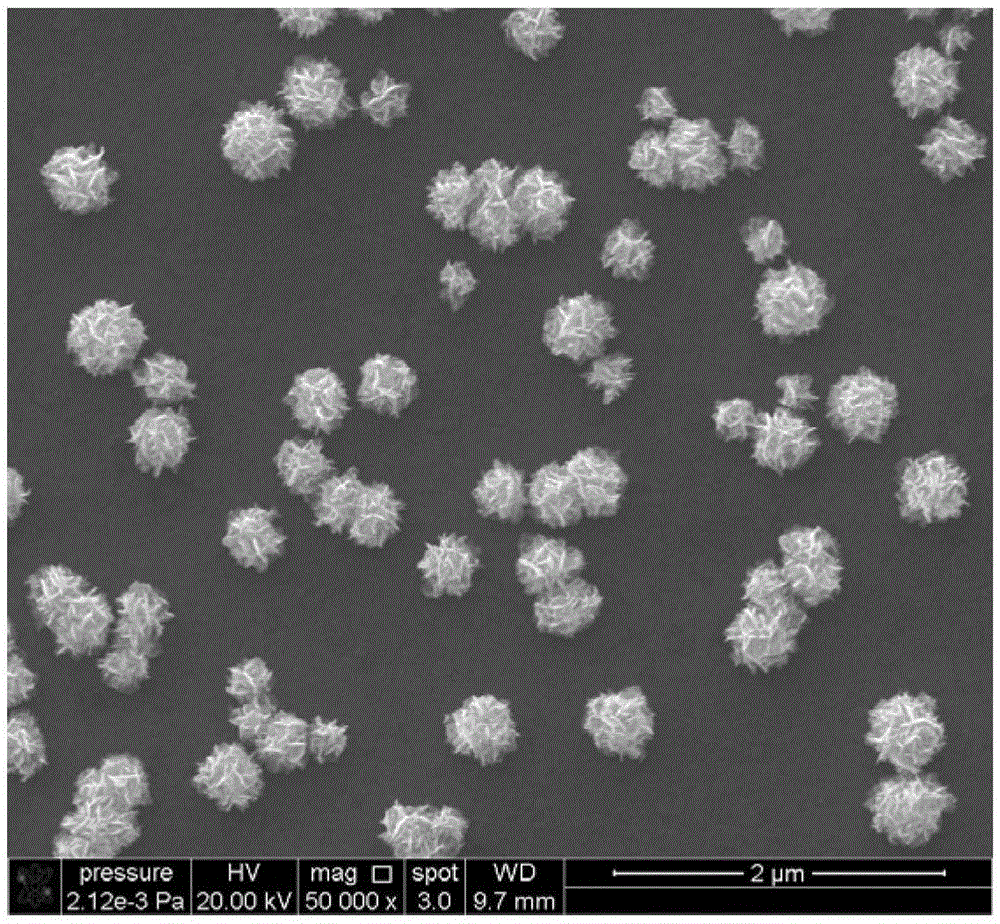

Embodiment 1

[0028] This embodiment relates to a method for preparing a Pt / ITO electrode with high catalytic activity, comprising the following steps:

[0029] Step 1: Prepare the working electrode,

[0030] (a) First put ITO in acetone, and perform ultrasonic cleaning for 10 minutes;

[0031] (b) connecting the wire to the conductive surface of the ITO processed through step (a) and wax and encapsulating it to obtain the working electrode;

[0032] Step 2: Assemble the three-electrode system,

[0033] The Pt counter electrode, the saturated calomel reference electrode, the ITO working electrode prepared in step 1 and the concentration are 5mmol / LH 2 PtCl 6 It is connected with the electrolyte solution mixed with two solutions with a concentration of 0.5mol / HCl to form a circuit to form a three-electrode system;

[0034] Step 3: Connect the three-electrode system in step 2 to the electrochemical workstation, the electrodeposition method is the constant potential method, the deposition ...

Embodiment 2

[0037] This embodiment relates to a method for preparing a Pt / ITO electrode with high catalytic activity, comprising the following steps:

[0038] Step 1: Prepare the working electrode,

[0039] (a) First put ITO in acetone, and perform ultrasonic cleaning for 10 minutes;

[0040] (b) connecting the wire to the conductive surface of the ITO processed through step (a) and wax and encapsulating it to obtain the working electrode;

[0041] Step 2: Assemble the three-electrode system,

[0042] The Pt counter electrode, the saturated calomel reference electrode, the ITO working electrode prepared in step 1 and the concentration are 5mmol / LH 2 PtCl 6 It is connected with the electrolyte solution mixed with two solutions with a concentration of 0.5mol / HCl to form a circuit to form a three-electrode system;

[0043] Step 3: Connect the three-electrode system in step 2 to the electrochemical workstation, the electrodeposition method is the constant potential method, the deposition ...

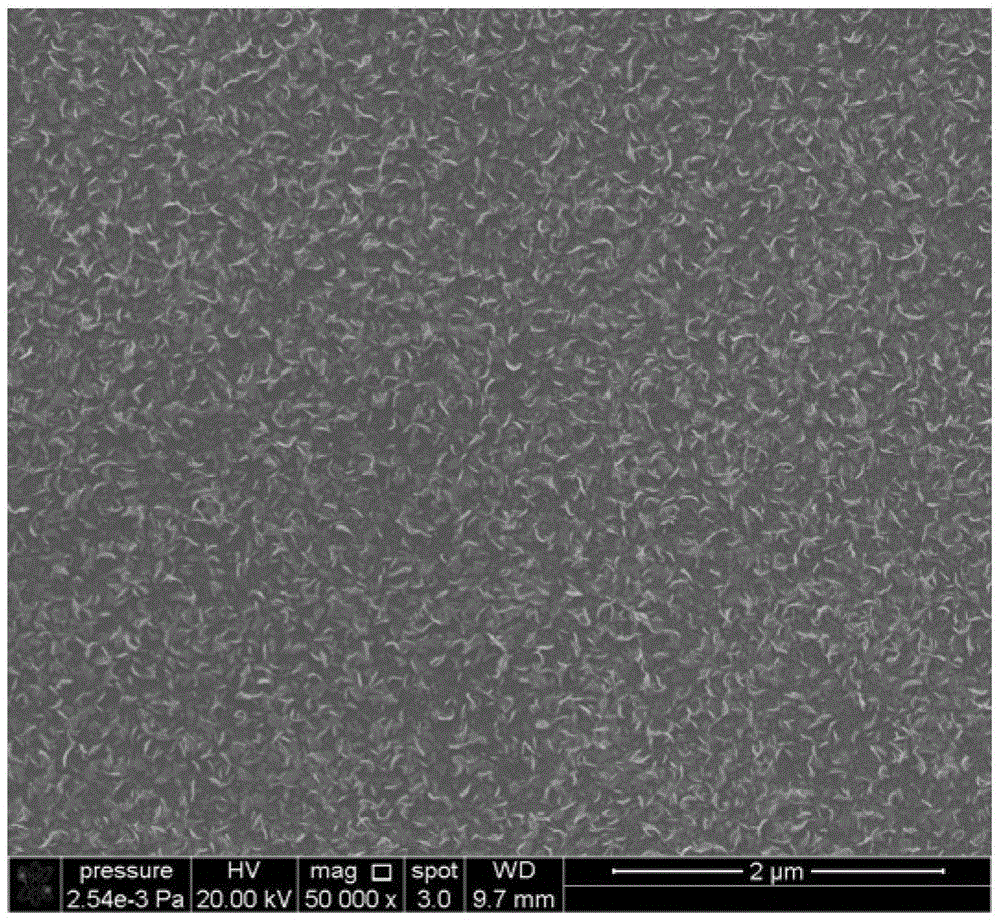

Embodiment 3

[0046] This embodiment relates to a method for preparing a Pt / ITO electrode with high catalytic activity, comprising the following steps:

[0047] Step 1: Prepare the working electrode,

[0048] (a) First put ITO in acetone, and perform ultrasonic cleaning for 10 minutes;

[0049] (b) connecting the wire to the conductive surface of the ITO processed through step (a) and wax and encapsulating it to obtain the working electrode;

[0050] Step 2: Assemble the three-electrode system,

[0051] The Pt counter electrode, the saturated calomel reference electrode, the ITO working electrode prepared in step 1 and the concentration are 5mmol / LH 2 PtCl 6 It is connected with the electrolyte solution mixed with two solutions with a concentration of 0.5mol / HCl to form a circuit to form a three-electrode system;

[0052]Step 3: Connect the three-electrode system in step 2 to the electrochemical workstation, the electrodeposition method is the constant potential method, the deposition v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com