Fabrication method of optical micro-nano biosensor integrated with microfluidic system

A microfluidic system and biosensor technology, applied in the field of biosensors, can solve the problems of high bonding time requirements, difficult alignment and bonding operations, and increase the difficulty of alignment and bonding, and achieve the effect of simplifying the operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

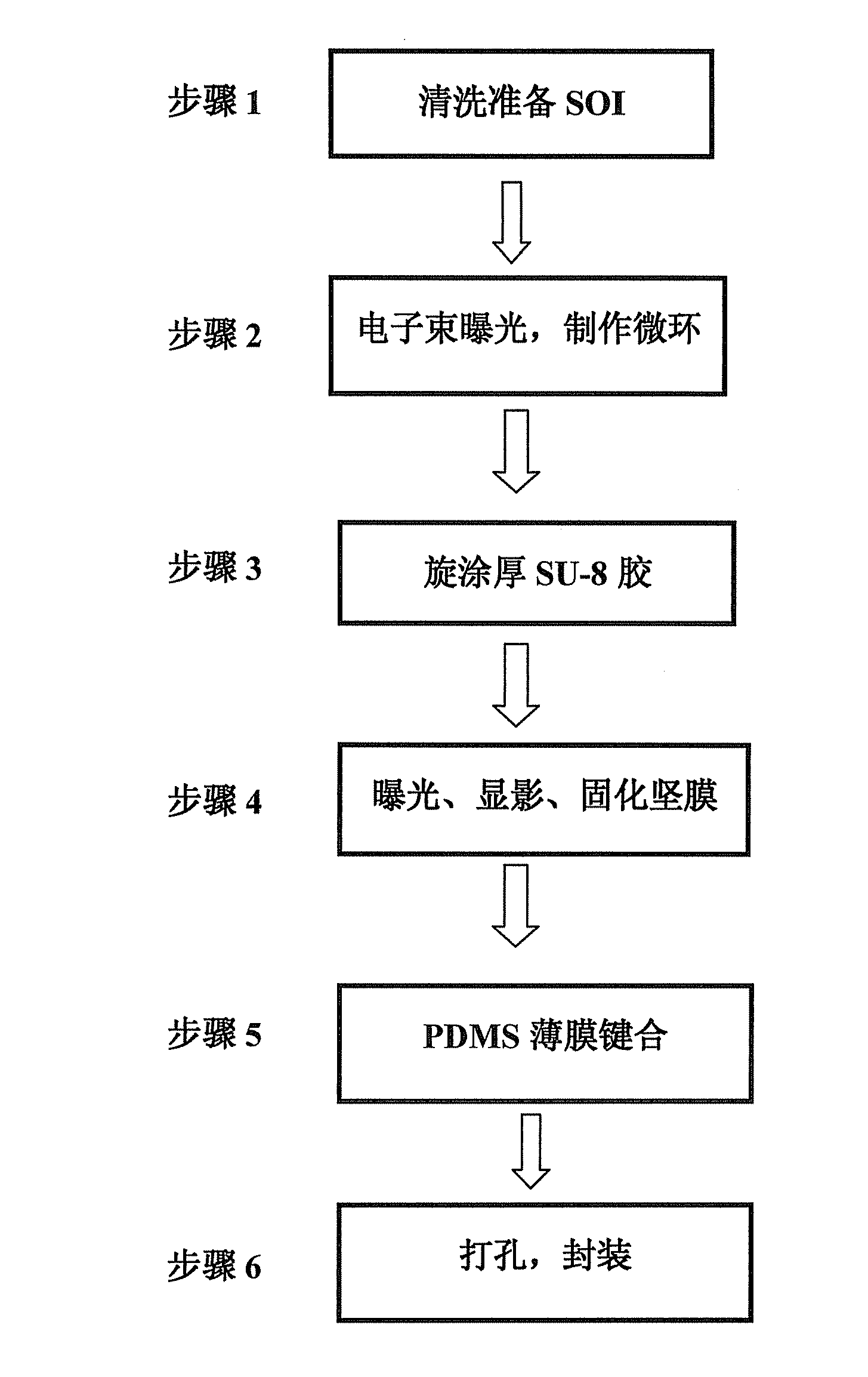

[0030] Such as figure 1 as shown, figure 1 It is a flowchart of a method for making an optical micro-nano biosensor integrated with a microfluidic system according to an embodiment of the present invention, the method includes the following steps:

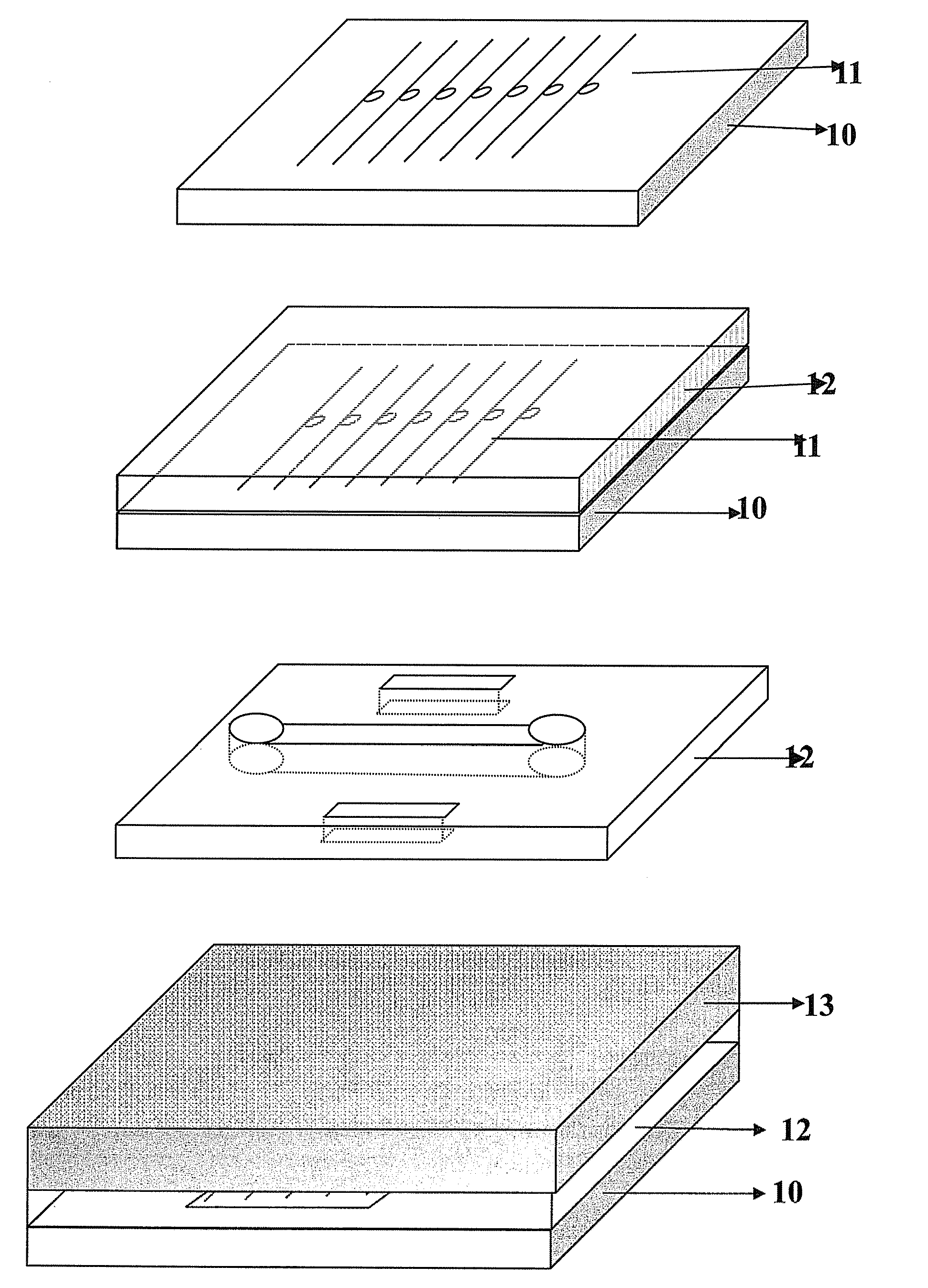

[0031] Step 1: Take a substrate 10, clean it, dry it, and apply adhesive and photoresist in sequence;

[0032] Step 2: exposing on the top layer of the substrate 10 to complete the definition of the device pattern;

[0033] Step 3: Etching and removing the glue on the developed substrate 10 to obtain a micro-nano planar waveguide optical device array chip 11;

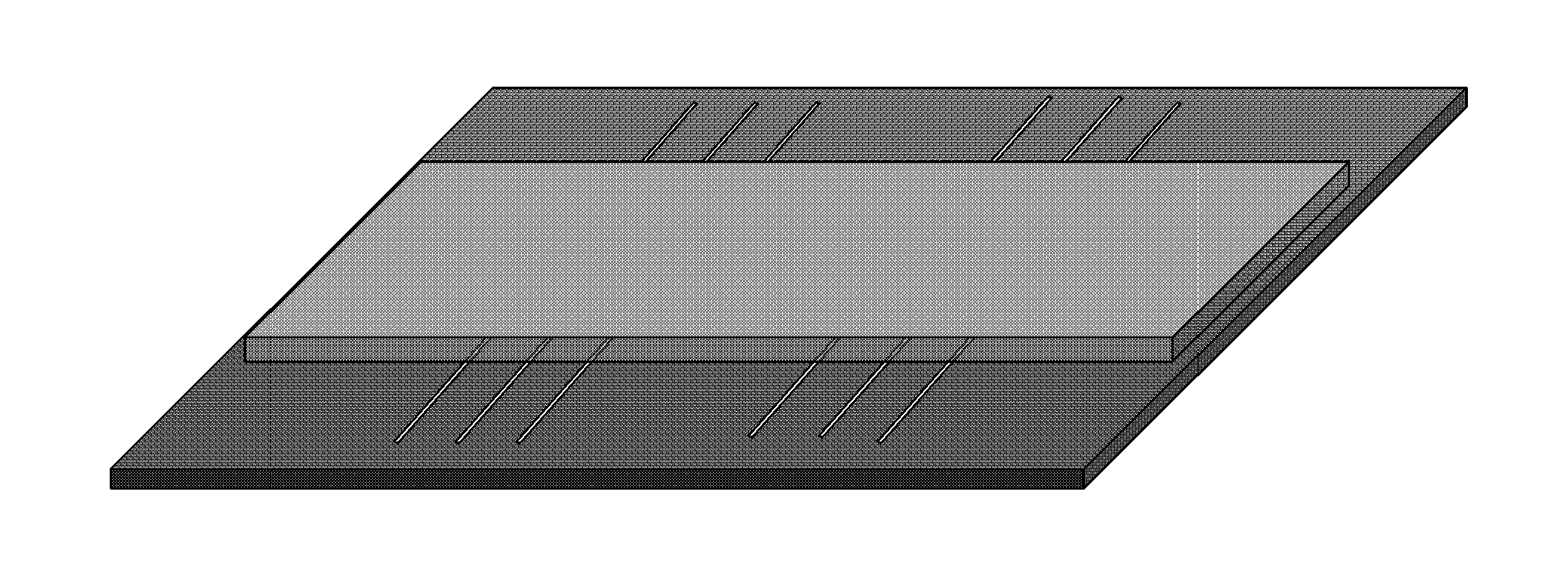

[0034] Step 4: Pre-baking the micro-nano planar waveguide optical device array chip 11, spin-coating SU8 glue 12 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com