Projection objective wave aberration on-line detection device and method based on double-beam interference

A technology of projection objective lens and detection device, which is applied in the direction of exposure device for photoengraving process, testing optical performance, exposure equipment for microlithography, etc. Process, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

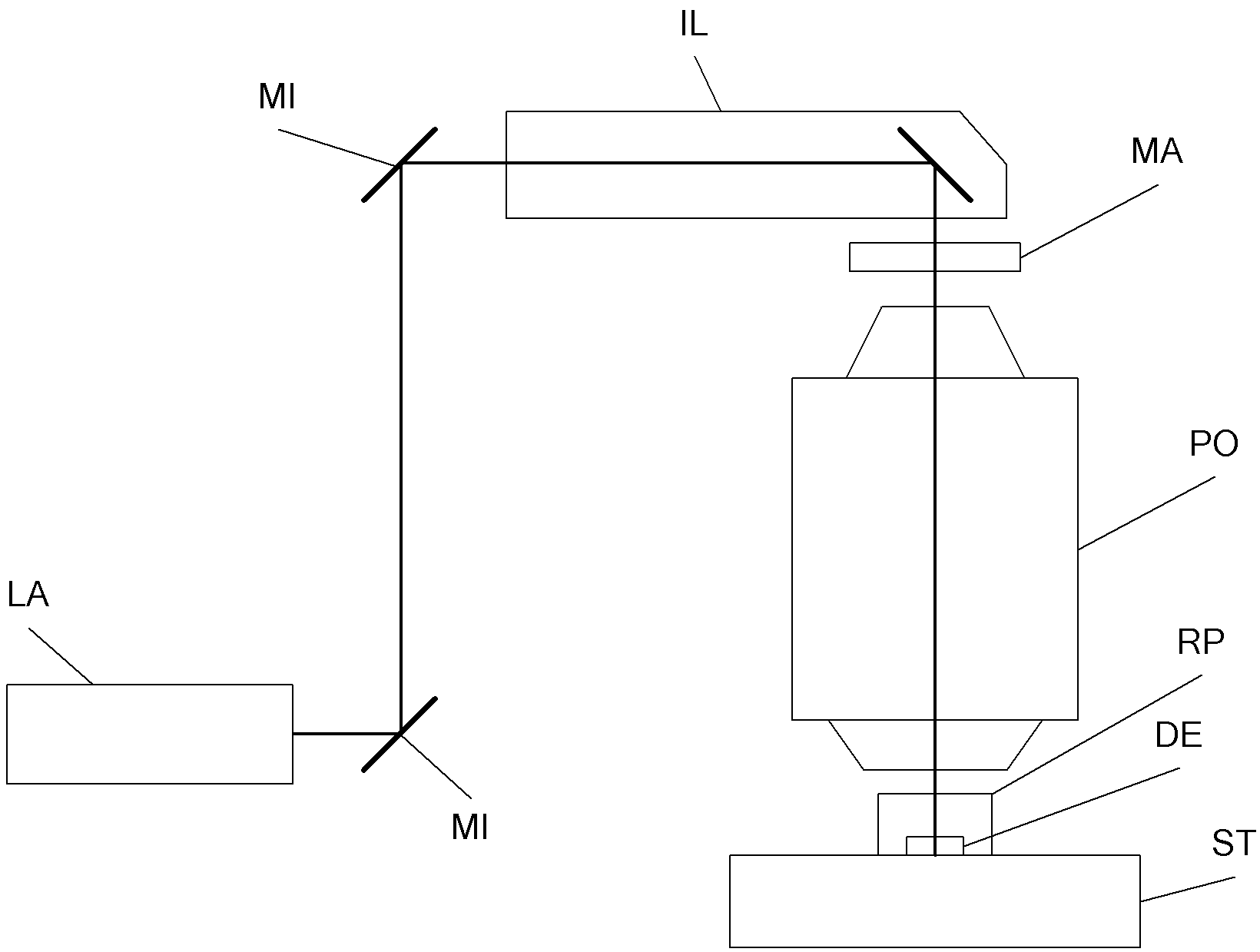

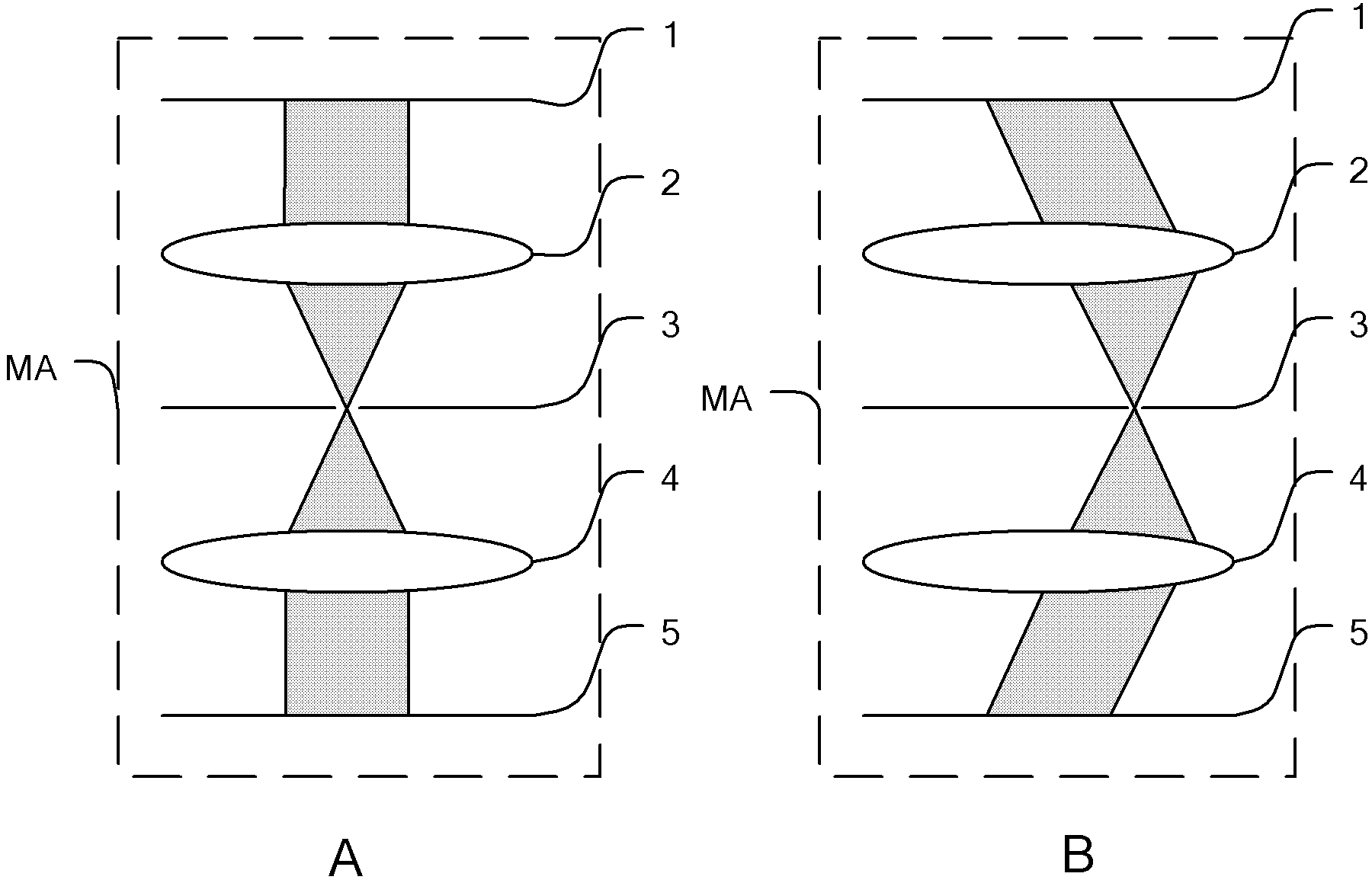

[0026] figure 2 is the optical path diagram of vertical and oblique coherent light generated by mask MA. like

[0027] figure 2 As shown, the mask MA of the present invention includes a diffuser 1 , a first lens 2 , a spatial filter 3 , a second lens 3 and a test mark 5 arranged in sequence along the optical path direction. The laser beam emitted by the illumination system IL is first irradiated on the diffusion sheet 1 of the mask MA. The main function of the diffusion sheet 1 is to further homogenize the laser beam. Optical element), microlens array, etc., the light beam passing through the diffusion sheet 1 is irradiated on the test mark 5 through the first lens 2, the spatial filter 3 and the second lens 3, and the first lens 2 and the second lens 4 form a lens group , so that the incident light beam forms a telecentric optical path, and the spatial filter 3 is arranged at the pupil plane of the lens group. The filter 3 is provided with a small hole, and the function...

Embodiment 2

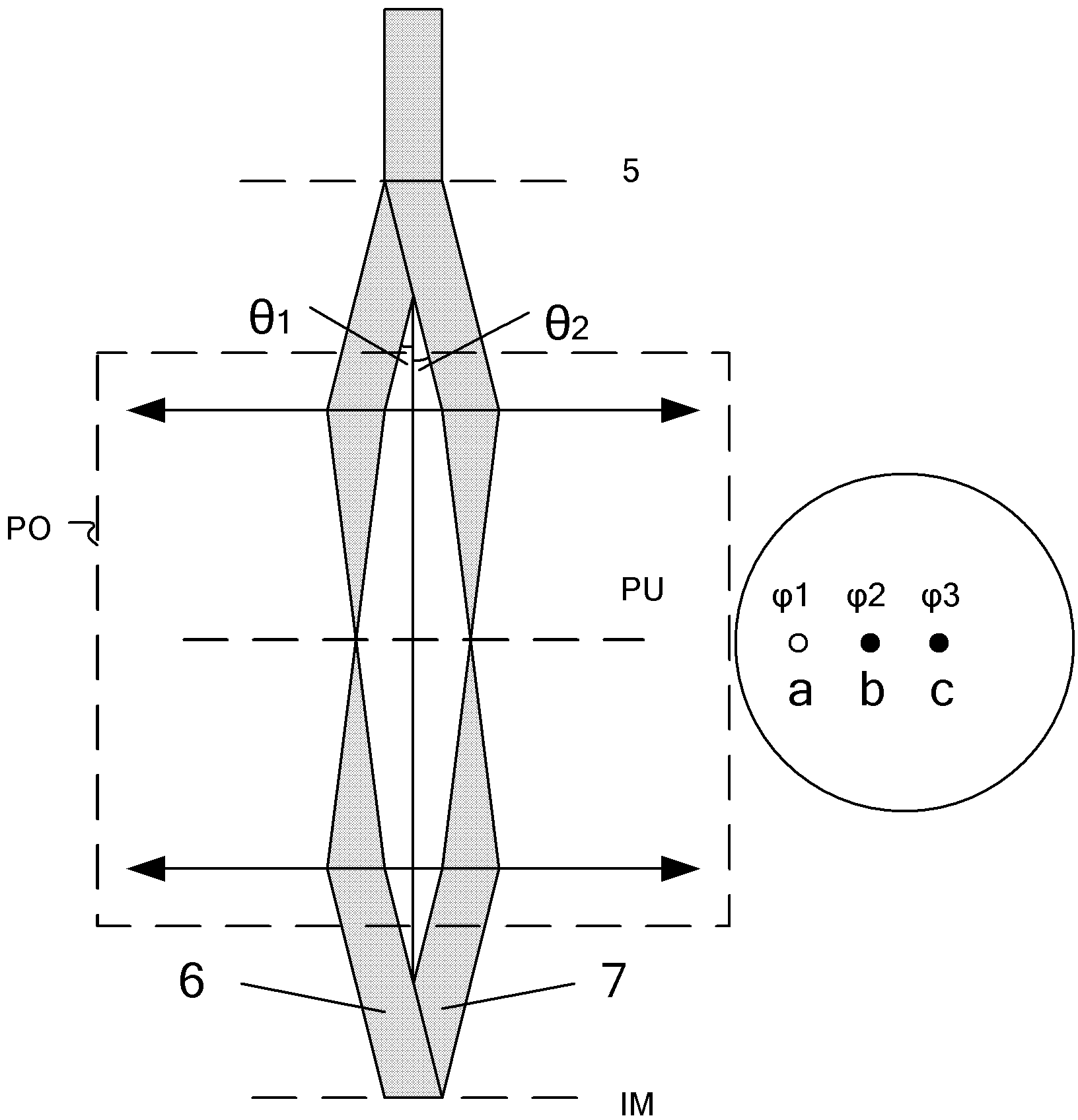

[0070] The key of the method for detecting the wave aberration of the projection objective lens of the present invention is to generate two coherent light beams at the position of the mask. In Embodiment 1, a phase grating is used, so that when the light beam passes through the projection objective lens, the aberration at two points is added, and the two points can be scanned and sampled along the pupil plane, so as to obtain the wave aberration of the entire projection objective lens. In embodiment 1, the illumination light path of the mask plate uses different positions of each small hole to complete scanning and sampling. In embodiment 2, a method of using a microprism array is used to complete the change of the beam direction, thereby realizing the diffraction beam alignment. Sampling of the pupil surface.

[0071] In Embodiment 2, the mask MA also includes a diffuser 1, a first lens 2, a spatial filter 3, a second lens 3, a microprism array 11 and a plurality of test mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com