Marchand balun provided with center tap and used for providing direct-current bias

A center tap, DC bias technology, applied in the information field, to achieve the effect of saving size and simplifying circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

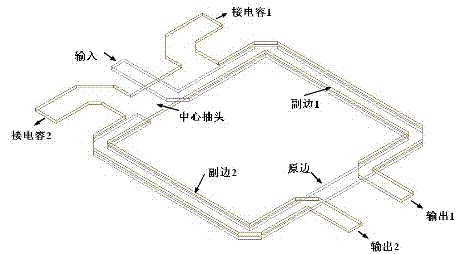

Embodiment 1

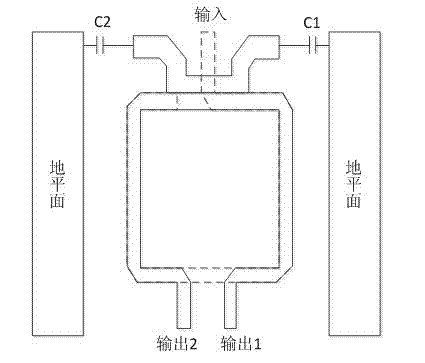

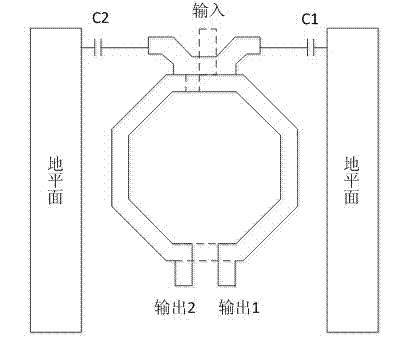

[0019] Taking the double-layer metal printed circuit board (PCB) manufacturing process as an example, the cross-sectional view of the printed circuit board is as follows: Figure 5 shown. The implementation process of the Marchunde balun with center tap proposed by the present invention is as follows: the metal layer 2 of the PCB is used for the primary side, the metal layer 1 of the PCB is used for the secondary side, the metal line of the primary side is folded into a square shape, the terminal is open, and the other end For signal input, the metal line width of the secondary side is the same as that of the primary side, and it is on the same vertical plane as the primary side, forming a wide-side coupling line. One end of secondary side 1 and secondary side 2 is output 1 and output 2 respectively, and the other end is connected to Together they constitute a center tap and are connected to capacitor 1 and capacitor 2 respectively, and the other ends of capacitor 1 and capaci...

Embodiment 2

[0021] Taking the CMOS 0.18 μm 7-layer metal integrated circuit process as an example, the cross-sectional view of the integrated circuit wafer is as follows Figure 6 shown. The implementation process of the Marchunde balun with center tap proposed by the present invention is as follows: the primary side is realized by using the metal layer M6, the secondary side is realized by using the top metal layer M7, the metal line of the primary side is folded into a square shape, the terminal is open, and the other end is Signal input, the metal line width of the secondary side is the same as that of the primary side, and it is on the same vertical plane as the primary side, forming a broadside coupling line. One end of secondary side 1 and secondary side 2 is output 1 and output 2 respectively, and the other ends are connected together It constitutes a center tap and is connected to capacitor 1 and capacitor 2 respectively, and the other ends of capacitor 1 and capacitor 2 are groun...

Embodiment 3

[0023] Taking the 4-layer metal printed circuit board (PCB) manufacturing process as an example, the cross-sectional view of the printed circuit board is as follows: Figure 7 shown. The implementation process of the Marchunde balun with center tap proposed by the present invention is as follows: the primary side and the secondary side can be realized by using any two metal layers of the PCB, the metal line of the primary side is folded into a square shape, the terminal is open, and the other end is a signal Input, the metal line width of the secondary side is the same as that of the primary side, and it is on the same vertical plane as the primary side, forming a wide-side coupling line. One end of the secondary side 1 and the secondary side 2 are respectively output 1 and output 2, and the other ends are connected together to form a The center tap is connected to capacitor 1 and capacitor 2 respectively, and the other ends of capacitor 1 and capacitor 2 are grounded. Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com