Preparation method of glycine trace element chelate with high purity

A trace element, chelate technology, applied in animal feed, animal feed, animal husbandry, etc., can solve the problems of increased cost, unfavorable digestion and absorption of animals, and low product purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

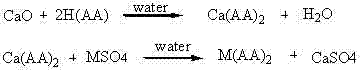

Method used

Image

Examples

Embodiment 1

[0014] Dissolve glycine (15g, 0.2mol) in 100ml water, add CaO5.7g (0.1mol) (or 7.4g Ca(OH) 2 ). The system was stirred until CaO was dissolved. After 30 min, copper sulfate pentahydrate (25.4 g, 0.1 mol) was added to the system. After a few minutes, the system became viscous and reacted for 30 minutes. After the reaction, 80ml of water was added to the system, the system was heated to 70-80°C, filtered, and the filter cake was washed twice with water. The filtrate was concentrated to dryness in vacuo. 21 g of a blue powder solid was obtained.

Embodiment 2

[0016] Glycine (25g, 0.33mol) was dissolved in 120ml of water, and CaO (9.5g, 0.168) was added. The system was stirred until CaO was dissolved. After 30 min, zinc sulfate heptahydrate (47.8 g, 0.165 g) was added to the system. After reacting for 30 minutes, filter and wash the filter cake twice with water. The filtrate was concentrated to dryness to obtain 35 g of white powder solid.

Embodiment 3

[0018] Dissolve glycine (15g, 0.2mol) in 100ml of water, add CaO (5.7g, 0.1mol) and stir the system until CaO is dissolved. After 30 minutes, manganese sulfate monohydrate (16.9 g, 0.1 mol) was added to the system. React for 30 minutes. After the reaction, filter and wash the filter cake twice with water. The filtrate was concentrated to dryness in vacuo. 20 g of a light brown powder solid was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com