Method for preparing gelatin protein and gold nanoparticle composite thin film and application of gelatin protein and gold nanoparticle composite thin film

A gold nanoparticle and composite film technology, which is applied in the field of preparation of gelatin protein gold nanoparticle composite film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

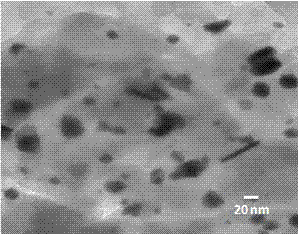

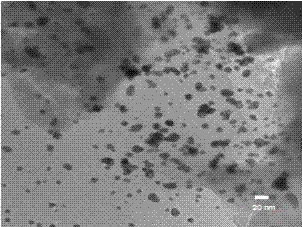

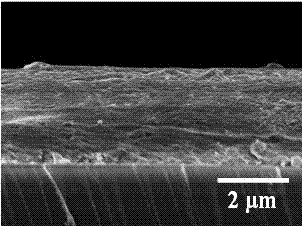

Image

Examples

Embodiment 1

[0016] 1) The same volume of 4mM copper nitrate aqueous solution and 1.4mM ethanolamine aqueous solution were mixed under magnetic stirring, and left for 2 days to generate Cu(OH) 2 Nanowire solution, 20ml Cu(OH) 2 Nanowire solution filtration forms a nanometer thick hydrophilic mesoporous membrane on a polycarbonate porous membrane with a pore size of 200 nm;

[0017] 2) Add 4.9ml Cu(OH) 2 The nanowire solution and 0.1ml of 1% gelatin solution were mixed and stirred for 5 minutes to obtain gelatin and Cu(OH) 2 Nanowire composite solution, and filtered onto the nanoscale thick hydrophilic mesoporous membrane, with 3ml, the glutaraldehyde solution that the mass percent is 2.5% glues together 2 hours, obtains gelatin Cu(OH) 2 Nanowire composite film, gelatin Cu(OH) 2 The nanowire composite film was removed from the polycarbonate porous membrane plate, and the Cu(OH) was removed by dilute hydrochloric acid with pH=2 2 nanowires, resulting in unsupported gelatin films;

[001...

Embodiment 2

[0021] 1) The same volume of 4mM copper nitrate aqueous solution and 1.4mM ethanolamine aqueous solution were mixed under magnetic stirring, and left for 3 days to generate Cu(OH) 2 Nanowire solution, 20ml Cu(OH) 2 Nanowire solution filtration forms a nanometer thick hydrophilic mesoporous membrane on a polycarbonate porous membrane with a pore size of 200 nm;

[0022] 2) Add 4.9ml Cu(OH) 2 The nanowire solution and 0.1ml of gelatin solution with a mass fraction of 1% were mixed and stirred for 6 minutes to obtain gelatin and Cu(OH) 2 Nanowire composite solution, and filtered onto the nano-scale thick hydrophilic mesoporous membrane, with 3ml, the glutaraldehyde solution of 2.5% by mass percent was glued for 3 hours to obtain gelatin Cu(OH) 2 Nanowire composite film, gelatin Cu(OH) 2 The nanowire composite film was removed from the polycarbonate porous membrane plate, and the Cu(OH) was removed by dilute hydrochloric acid with pH=2 2 nanowires, resulting in unsupported gel...

Embodiment 3

[0026] 1) The same volume of 4mM copper nitrate aqueous solution and 1.4mM ethanolamine aqueous solution were mixed under magnetic stirring, and left for 3 days to generate Cu(OH) 2 Nanowire solution, 20ml Cu(OH) 2 Nanowire solution filtration forms a nanometer thick hydrophilic mesoporous membrane on a polycarbonate porous membrane with a pore size of 200 nm;

[0027] 2) Add 4.9ml Cu(OH) 2 The nanowire solution and 0.1ml of gelatin solution with a mass fraction of 1% were mixed and stirred for 6 minutes to obtain gelatin and Cu(OH) 2 Nanowire composite solution, and filtered onto the nano-scale thick hydrophilic mesoporous membrane, with 3ml, the glutaraldehyde solution of 2.5% by mass percent was glued for 3 hours to obtain gelatin Cu(OH) 2 Nanowire composite film, gelatin Cu(OH) 2 The nanowire composite film was removed from the polycarbonate porous membrane plate, and the Cu(OH) was removed by dilute hydrochloric acid with pH=2 2 nanowires, resulting in unsupported gel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com