Municipal solid waste processing system and processing method

A municipal solid waste treatment system technology, applied in the municipal solid waste treatment system and its treatment field, can solve the problems of waste of recyclable resources, difficulty in control, high investment and operation costs, etc., and achieve the effect of improving resource reuse rate and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

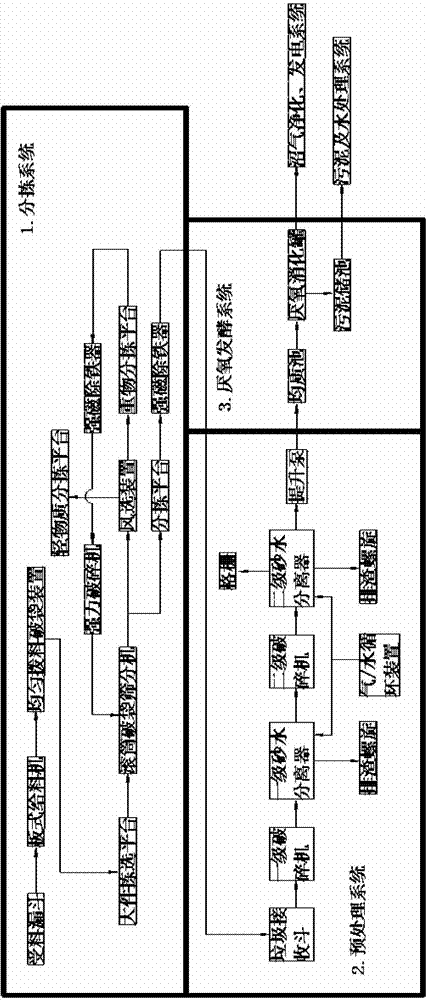

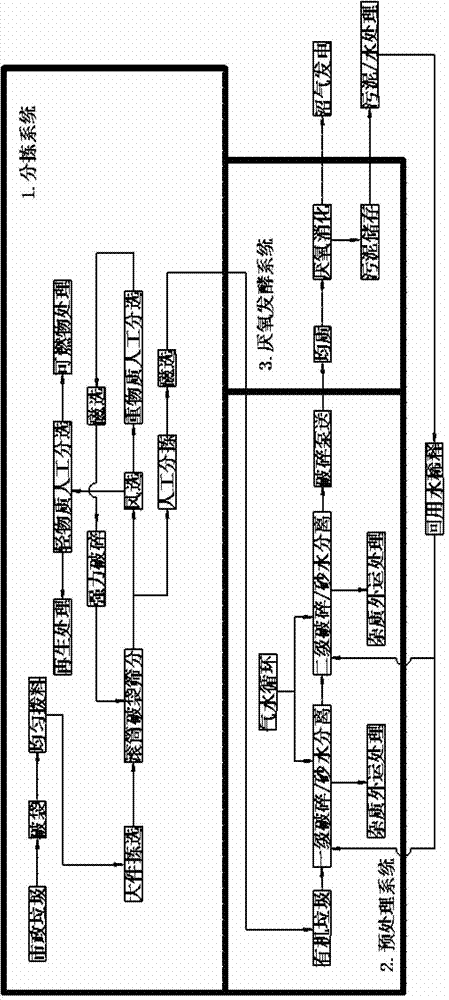

[0029] A treatment method for municipal solid waste, the operation steps are:

[0030] (1) Weigh the municipal waste, divide the material evenly after breaking the bag, and classify the mixed waste through a combination of machine screening, winnowing and manual sorting;

[0031] (2) Shred the selected organic waste;

[0032] (3) The crushed material is diluted first, and after dilution, the inorganic matter with a large specific gravity at the bottom is removed through the spiral slag discharge treatment, the floating matter on the water surface is removed through the grid, and the remaining organic materials are further crushed by the rotary crushing device;

[0033] (4) Mesophilic anaerobic fermentation is carried out on organic waste materials from which inorganic substances have been removed.

[0034] Among them, when the mixed garbage in step (1) is sorted and processed, the degradable organic matter is magnetically separated by the belt conveyor and then enters the rec...

Embodiment 2

[0039] Different from Example 1, the process parameters during anaerobic fermentation are different. The solid content of the anaerobic digestion tank feed is 5%, the average solid content in the tank is 3%, the residence time is 25 days, and the particle size of the organic material is 8mm, the degradation rate of organic matter is high, and the gas production rate is also high.

Embodiment 3

[0041] Different from Example 1, the process parameters during anaerobic fermentation are different. The solid content of the anaerobic digestion tank feed is 4%, the average solid content in the tank is 2.5%, the residence time is 30 days, and the particle size of the organic material is 5mm, the degradation rate of organic matter is high, and the gas production rate is also high.

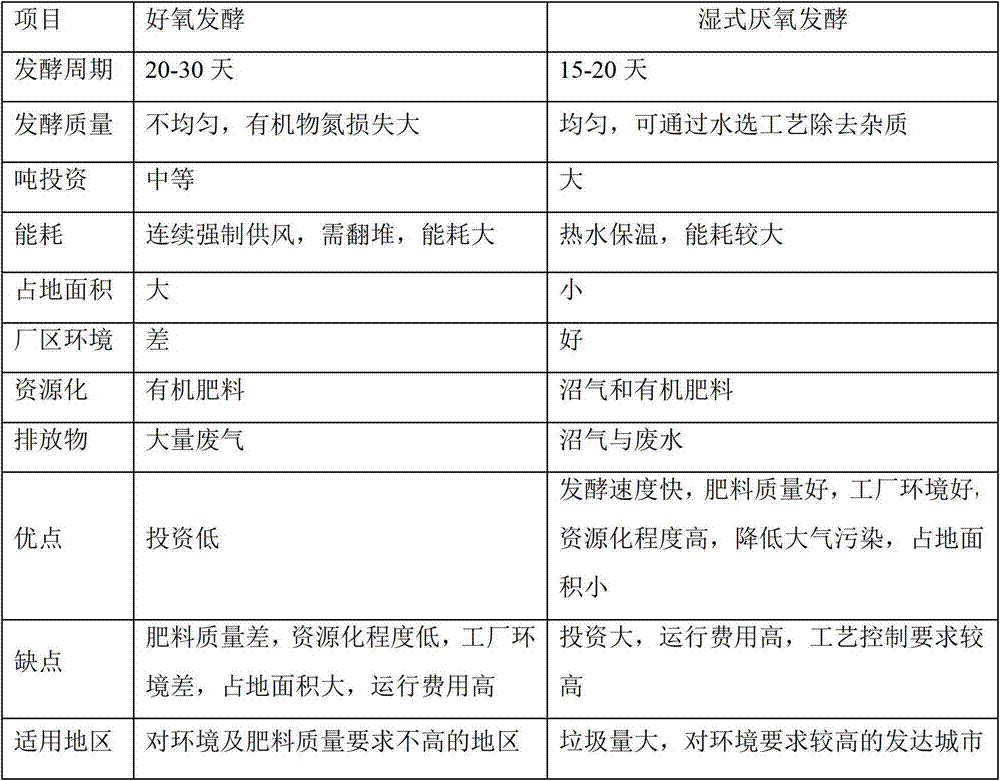

[0042] What the present invention adopted is anaerobic fermentation, wherein the advantages and disadvantages of aerobic fermentation and anaerobic fermentation are compared as shown in Table 1:

[0043] Table 1 Comparative analysis of aerobic fermentation and anaerobic fermentation

[0044]

[0045] Anaerobic fermentation decomposes carbohydrates, proteins, and fats under anaerobic conditions, through the synergistic action of a variety of bacteria, first decomposes them into simple and stable substances, continues to act, and finally generates the main components of biogas such as methane and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com