Red copper rolling cleaning agent and production method thereof

A cleaning agent and red copper technology, applied in the field of cleaning agents, can solve the problems of easily corroded workpieces and greater health hazards for on-site operators, and achieve the effects of corrosion inhibition, good solubility and stability, and reduced surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

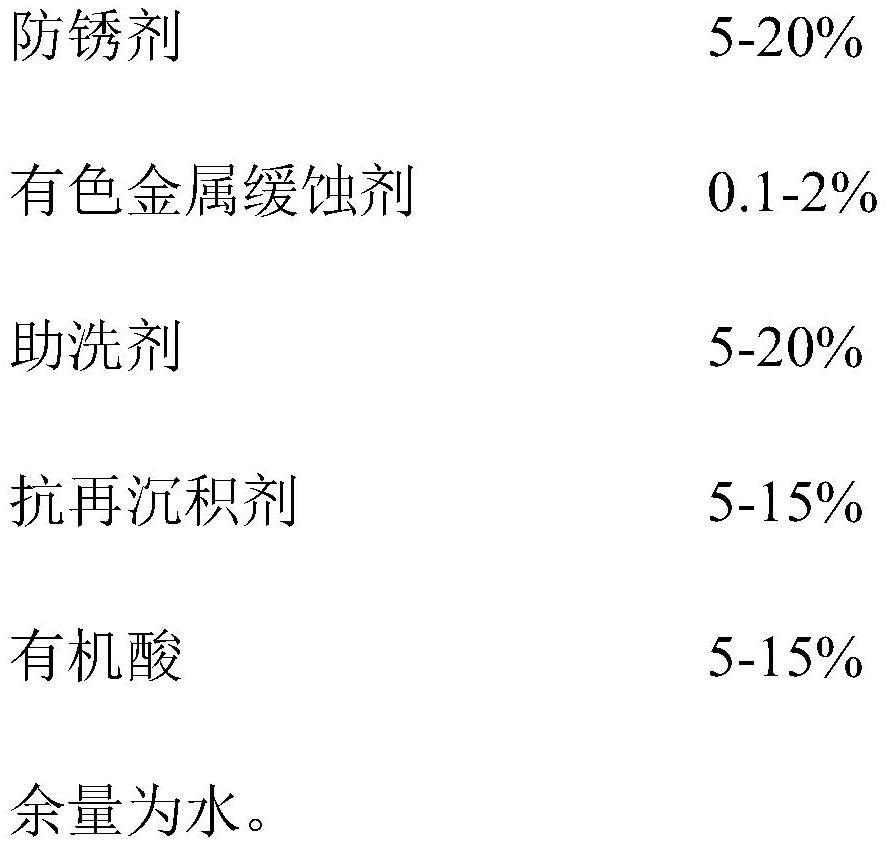

[0028] The percentage by weight of each component in the red copper rolling cleaning agent of the present embodiment is as follows:

[0029] Alkylphenol ethoxylates 10%, azabenzenecyclopolyaminocaproic acid 20%, hydroxybenzotriazole 0.1%, potassium hydroxide 20%, triethanolamine 5%, isononanoic acid 5% and water 39.9% .

[0030] The preparation method of the red copper rolling cleaning agent of the present embodiment is:

[0031] Weigh azabenzenecyclopolyaminocaproic acid, hydroxybenzotriazole and triethanolamine by weight percentage, add them into water in turn under stirring, raise the temperature to 50°C, stir until the materials are completely dissolved, then slowly cool down to 40°C , and then add alkylphenol polyoxyethylene ether, potassium hydroxide and isononanoic acid respectively, and continue to stir for 0.5h until the solution is transparent to obtain a cleaning agent for copper rolling.

Embodiment 2

[0033] The percentage by weight of each component in the red copper rolling cleaning agent of the present embodiment is as follows:

[0034] Fatty Alcohol Alkoxylate 20%, Sebacic Acid 5%, Silicone 2%, Disodium EDTA 5%, Oleamide 15%, Isononanoic Acid 15% and Water 38%.

[0035] The preparation method of the red copper rolling cleaning agent of the present embodiment is:

[0036] Weigh sebacic acid, siloxane and oleic acid amide according to weight percentage, add them into water in turn under stirring, raise the temperature to 60°C, stir until the materials are completely dissolved, then slowly cool down to 30°C, and then add fatty alcohols respectively Alkoxylates, disodium edetate and isononanoic acid were stirred for 1 hour until the solution was transparent to obtain a cleaning agent for copper rolling.

Embodiment 3

[0038] The percentage by weight of each component in the red copper rolling cleaning agent of the present embodiment is as follows:

[0039] Sodium alkylbenzenesulfonate 15%, dodecanedioic acid 10%, siloxane 1%, sodium nitrilotriacetate 10%, oleic acid amide 10%, isononanoic acid 10% and water 44%.

[0040] The preparation method of the red copper rolling cleaning agent of the present embodiment is:

[0041] Weigh dodecanedibasic acid, siloxane and oleic acid amide according to weight percentage, add them into water in turn under stirring, raise the temperature to 55°C, stir until the materials are completely dissolved, then slowly cool down to 20°C, and then separate Add sodium alkylbenzene sulfonate, sodium nitrilotriacetate and isononanoic acid, and continue stirring for 1.5 h until the solution becomes transparent to obtain a cleaning agent for copper rolling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com