Process for super-refining treatment of rejection water of low permeability oilfield and compound drive oilfield

A technology of oilfield reinjection water and process method, which is applied in ultra-fine treatment of low permeability oilfield and compound flooding oilfield reinjection water, low permeability oilfield and compound flooding oilfield reinjection water field, can solve poor operation stability, secondary pollution, sludge is very Difficult to deal with and other problems, to achieve the effect of high equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

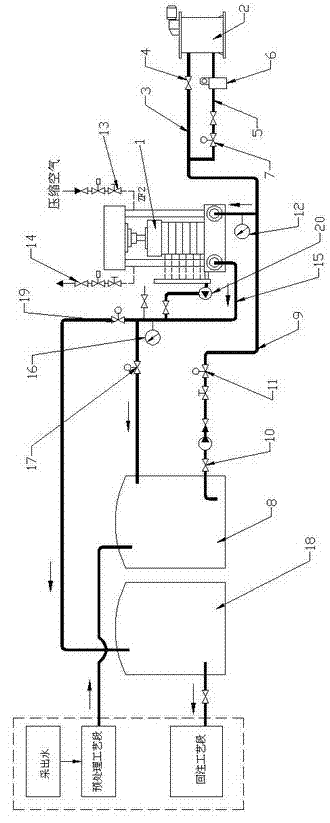

[0024] The process of the ultra-fine treatment system for reinjection water in low-permeability oilfields and composite flooding oilfields is as follows:

[0025] 1), pre-coating: open the first automatic valve 7 and the first flow control valve 17, start the main machine 1, the mixing tank 2 and the adding pump 6, the filtrate in the mixing tank 2 enters the main machine 1 through the adding pump 6, and the filtrate passes through the main machine 1 Afterwards, pass into the second liquid storage tank 8, and the filtrate is pre-coated with a layer of film on the filter plate in the main machine 1; the film and the filter plate of the main machine 1 form the main machine filter element;

[0026] 2) Internal circulation: open the second automatic valve 10 and the second flow control valve 11, the dirty liquid in the second liquid storage tank 8 is mixed with the filtrate through the first filter pump and enters the main machine 1 through the inlet of the main machine 1, and ...

Embodiment 2

[0031] The process of the ultra-fine treatment system for reinjection water in low-permeability oilfields and composite flooding oilfields is as follows:

[0032] 1), pre-coating: open the first automatic valve 7 and the first flow control valve 17, start the main machine 1, the mixing tank 2 and the adding pump 6, the filtrate in the mixing tank 2 enters the main machine 1 through the adding pump 6, and the filtrate passes through the main machine 1 Afterwards, pass into the second liquid storage tank 8, and the filtrate is pre-coated with a layer of film on the filter plate in the main machine 1; the film and the filter plate of the main machine 1 form the main machine filter element;

[0033] 2) Internal circulation: open the second automatic valve 10 and the second flow control valve 11, the dirty liquid in the second liquid storage tank 8 is mixed with the filtrate through the first filter pump and enters the main machine 1 through the inlet of the main machine 1, and ...

Embodiment 3

[0038] The process of the ultra-fine treatment system for reinjection water in low-permeability oilfields and composite flooding oilfields is as follows:

[0039] 1), pre-coating: open the first automatic valve 7 and the first flow control valve 17, start the main machine 1, the mixing tank 2 and the adding pump 6, the filtrate in the mixing tank 2 enters the main machine 1 through the adding pump 6, and the filtrate passes through the main machine 1 Afterwards, pass into the second liquid storage tank 8, and the filtrate is pre-coated with a layer of film on the filter plate in the main machine 1; the film and the filter plate of the main machine 1 form the main machine filter element;

[0040] 2) Internal circulation: open the second automatic valve 10 and the second flow control valve 11, the dirty liquid in the second liquid storage tank 8 is mixed with the filtrate through the first filter pump and enters the main machine 1 through the inlet of the main machine 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com