Phosphorus-removing method based on nano-grade iron

A technology of nano-iron and limonite, which is applied in the fields of chemical instruments and methods, water/sludge/sewage treatment, adsorption water/sewage treatment, etc. It can solve the problems of undeveloped phosphorus removal materials, limited adsorption capacity, low adsorption capacity, etc. problems, to achieve the effect of abundant reserves, large adsorption capacity and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

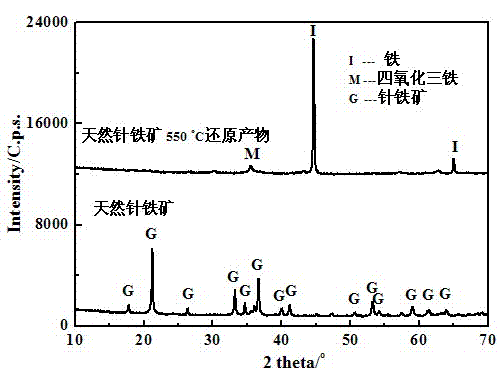

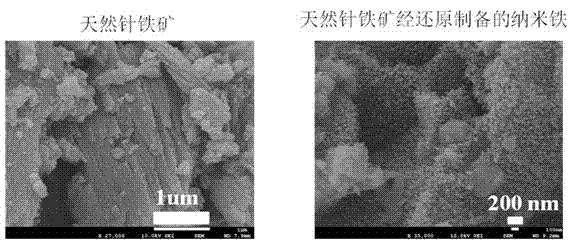

Embodiment 1

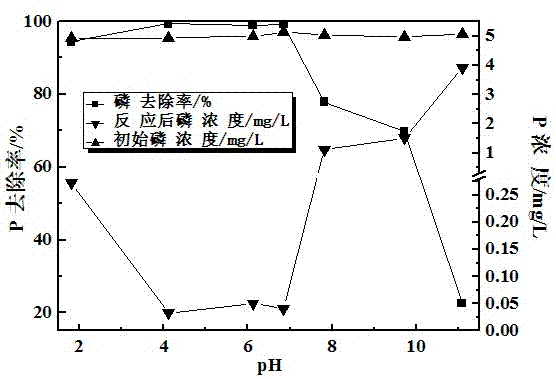

[0028] The preparation method of nano-iron in this example: select limonite ore with a goethite content of 70%, crush the ore, and sieve to obtain a sample of 0.25-0.5 mm, roast it in a hydrogen atmosphere at a temperature of 550 ° C for 3 hours, and then Cool to room temperature under a nitrogen atmosphere, take it out and seal it for storage to obtain nano-iron. The amount of feeding hydrogen is calculated according to 100-150% of the theoretical dosage for reducing ferric iron to zero-valent iron.

[0029] Water treatment method: fill the prepared material into a test column with a diameter of 12mm and a height of 60mm, and the effective height of the filler is 30mm. Prepare simulated phosphorous-containing wastewater with a phosphorus concentration of 5mg / L and a pH of 6.8, and operate with a hydraulic retention time of 1.5 hours. The phosphorus concentration in the effluent is kept below 0.1mg / L, the phosphorus removal rate is higher than 98%, and the phosphorus concentra...

Embodiment 2

[0032] This is an example of the preparation method of nano-iron: select limonite ore with a goethite content of 90%, crush the ore, and sieve to obtain a sample of 0.25-0.5 mm, roast it in a carbon monoxide atmosphere at 700 ° C for 3 hours, and then dry it under nitrogen. Cool to room temperature under the atmosphere, take it out and seal it for storage, and obtain nano-iron. The amount of feeding carbon monoxide is calculated according to 100-150% of the theoretical dosage for reducing ferric iron to zero-valent iron.

[0033] Water treatment method: fill the prepared material into a test column with a diameter of 12mm and a height of 60mm, and the effective height of the filler is 30mm. Prepare simulated phosphorous-containing wastewater with a phosphorus concentration of 5mg / L and a pH of 4.2, and operate it with a hydraulic retention time of 3 hours. The phosphorus concentration in the effluent is kept below 0.1mg / L, the phosphorus removal rate is higher than 98%, and th...

Embodiment 3

[0035] Water treatment method: put the material prepared in Example 1 into an experimental column with a diameter of 12 mm and a height of 60 mm, and the effective height of the filler is 30 mm. Prepare simulated phosphorus-containing wastewater with a phosphorus concentration of 2 mg / L and a pH of 6.8, and operate with a hydraulic retention time of 1.5 hours. The phosphorus concentration in the effluent is kept below 0.02mg / L, the phosphorus removal rate is higher than 98%, and the phosphorus concentration in the effluent reaches the first-class standard for surface water bodies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com