Rustproof lubricating agent

A technology of anti-rust lubricant and anti-corrosion agent, which is applied in the direction of lubricating composition and petroleum industry, etc. It can solve the problems of unsuitable automatic cleaning machines, etc., and achieve the effect of preventing corrosion, preventing redox reaction and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

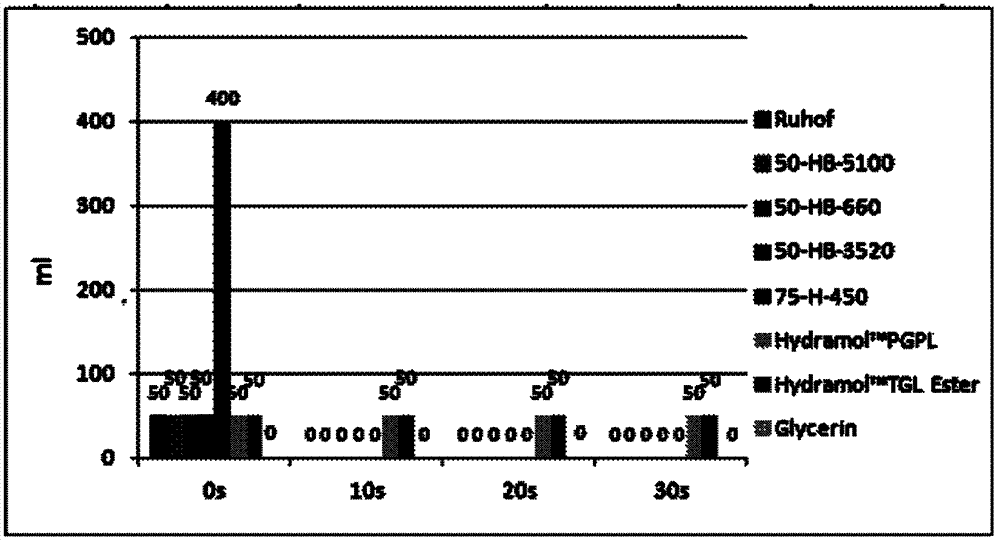

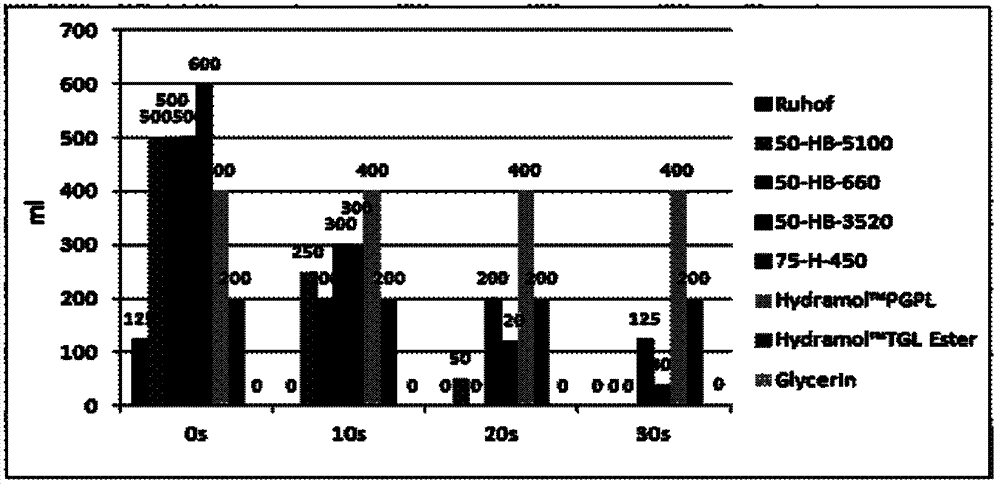

[0052] A. Foam level test

[0053] Since the lubricant is to be used in automatic washing machines, it is preferred to select a formulation with a low foam content. Screening tests for base oils were performed using the Foam Level Test (STM 100).

[0054] 1) Dilute 5% oil solution with distilled water at 25°C or 60°C at 1:200;

[0055] 2) Put the diluted solution into a beaker and record the initial height of the solution (the volume value marked in ml is recorded as the height, and the suitable final volume is 500ml);

[0056] 3) Mix the solution at high speed in a blender (Philips Comfort) for 20 seconds;

[0057] 4) stop stirring and record the height of the solution foam at 0, 10, 20 and 30 seconds respectively;

[0058] 5) Calculate the foam height:

[0059] Foam height = total height at the time of recording - initial solution height.

[0060] The foam height within 20 seconds is less than 50ml is the preferred base oil.

[0061] Table 1 shows the base oils evaluat...

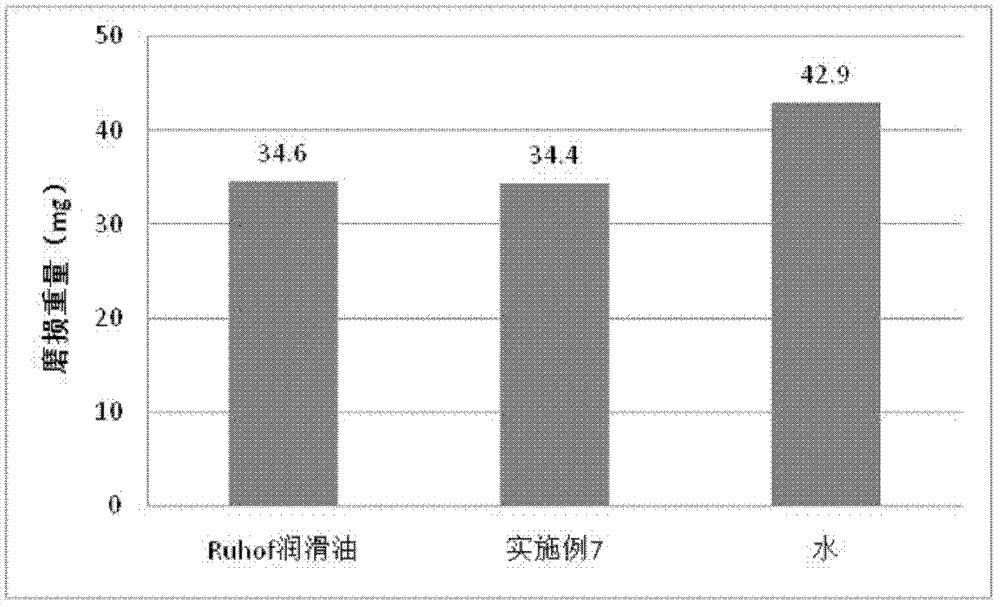

Embodiment 1

[0072]

Embodiment 2

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com