A liner completion method combining expandable casing and expandable screen

The technology of expanding casing and screen is applied in the field of oil drilling and completion, which can solve problems such as unfavorable production and convenient operation, and achieve the effects of improving sand control effect, increasing productivity and recovery rate, and large diameter size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

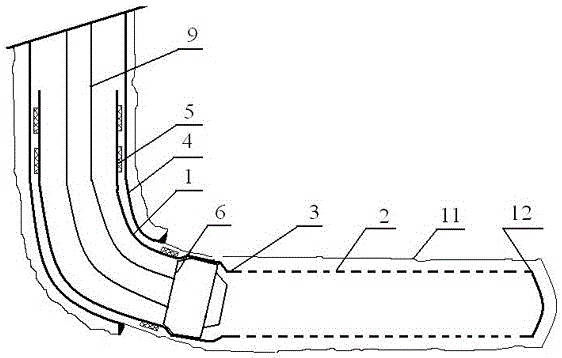

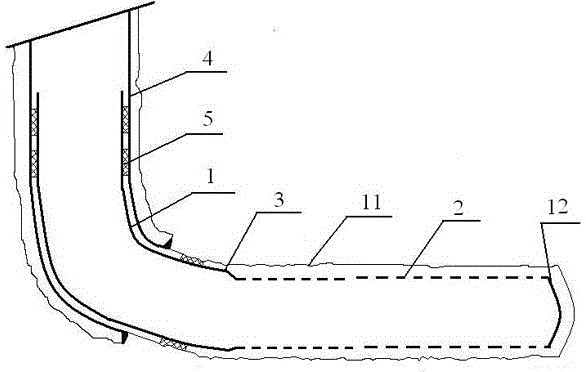

[0025] Assembly of the completion string: After the lower end of the expansion casing 1 is pre-expanded, the starting device 6 is inserted, the center pipe 9 passes through the expansion casing 1 and is connected to the starting device 6, and the bottom end of the expansion casing 1 passes through the conversion joint 3 and the expansion The screen pipes 2 are connected, and guide shoes 12 are connected at the bottom of the expansion screen pipe 2; among them, a plurality of sections of rubber rings 5 are arranged at intervals on the outer wall of the expansion sleeve 1, and the starting device 6 forms a sliding expansion fit with the inner wall of the expansion sleeve 1, and the starting device 6 The sum of the maximum outer diameter and the wall thickness of the expansion sleeve 1 is slightly smaller than the inner diameter of the technical sleeve 4, and the sum of the maximum outer diameter of the starting device 6 and the wall thickness of the rubber ring 5 and the expansi...

Embodiment 2

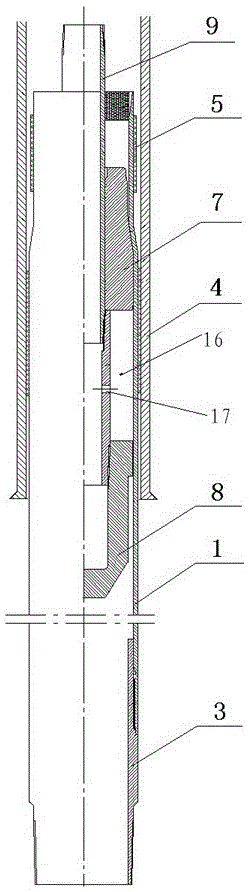

[0027] Embodiment 2: On the basis of Embodiment 1, the described start-up device 6 is to connect the sealing plug 8 at the bottom of the central tube 9, and the sealing plug 8 is provided with an expansion cone 7 at intervals upward to form an expansion chamber 16, and the interval between them is A radial guide tube 17 connected to the inside of the central tube 9 is provided. The expansion cone 7 is a cone through-hole structure with a narrow top and a wide bottom. The bottom of the sealing plug 8 is provided with a ball seat through hole that cooperates with a metal ball. The expansion cone 7 and the sealing The plugs 8 form a sealing fit with the expansion sleeve 1 respectively.

[0028] According to the construction process of the aforesaid starting device, after running the starting device 6 in the completion string to the bottom position of the downhole technical casing 4, a metal ball is put into the center pipe 9 from the wellhead, and set until it is installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com