Optical reflecting film used for backlight units

An optical reflection and backlight module technology, applied in optics, optical components, chemical instruments and methods, etc., can solve the problems of scratches and wrinkles of the reflective film, affecting the brightness and picture quality of the backlight source and display, and improve the reflectivity. , The effect of improving stiffness and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

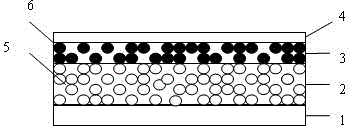

Image

Examples

Embodiment 1

[0034] 1. Configuration of H-layer coating solution:

[0035] Add methyl ethyl ketone and toluene to the biphenyl resin, dissolve the resin, then add 10 micron titanium dioxide particles into the dissolved resin, then add leveling agent and initiator (or curing agent), and disperse evenly under high stirring. Obtain the H-layer coating solution whose weight content of titanium dioxide is 40%, and set aside.

[0036] 2. Configuration of L layer coating solution:

[0037] Dilute the fluorine-containing resin with methyl ethyl ketone and toluene, then add leveling agent and initiator (or curing agent), and disperse evenly under high-speed stirring to obtain a .L-layer coating solution for future use.

[0038] 3. Preparation of reflective film:

[0039] Crystallize polyethylene terephthalate polyester chips with an intrinsic viscosity of 0.65dl / g at 170°C, dry, and then feed the crystallized material into the substrate layer extruder to melt and extrude at 275°C ; The polyethyl...

Embodiment 2

[0041] 1. Configuration of H-layer coating solution:

[0042] Add methyl ethyl ketone and toluene to the biphenyl resin, dissolve the resin, then add 25 micron titanium dioxide particles into the dissolved resin, then add leveling agent and initiator (or curing agent), and disperse evenly under high stirring. Obtain the H-layer coating solution whose weight content of titanium dioxide is 50%, and set aside.

[0043] 2. Configuration of L layer coating solution:

[0044] Dilute the fluorine-containing resin with methyl ethyl ketone and toluene, then add leveling agent and initiator (or curing agent), and disperse evenly under high-speed stirring to obtain a .L-layer coating solution for later use.

[0045] 3. Preparation of reflective film:

[0046] Crystallize polyethylene terephthalate polyester chips with an intrinsic viscosity of 0.65dl / g at 170°C, dry, and then feed the crystallized material into a substrate layer extruder for melt extrusion at 275°C ; The polyethylene ...

Embodiment 3

[0048] 1. Configuration of H-layer coating solution:

[0049] Add methyl ethyl ketone and toluene to the biphenyl resin, dissolve the resin, then add 40 micron titanium dioxide particles into the dissolved resin, then add leveling agent and initiator (or curing agent), and disperse evenly under high stirring. Obtain the H-layer coating solution whose weight content of titanium dioxide is 50%, and set aside.

[0050] 2. Configuration of L layer coating solution:

[0051] Dilute the fluorine-containing resin with methyl ethyl ketone and toluene, then add leveling agent and initiator (or curing agent), and disperse evenly under high-speed stirring to obtain a .L-layer coating solution for future use.

[0052] 3. Preparation of reflective film:

[0053] Crystallize polyethylene terephthalate polyester chips with an intrinsic viscosity of 0.65dl / g at 170°C, dry, and then feed the crystallized material into a substrate layer extruder for melt extrusion at 275°C ; The polyethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com