Residual oil hydrogenation method for high quality diesel oil yield increase

A technology for residual oil hydrogenation and diesel oil, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of shortening the operation period of carbon deposits in the bed, stopping the operation to replace the catalyst, and increasing the hydrogen consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

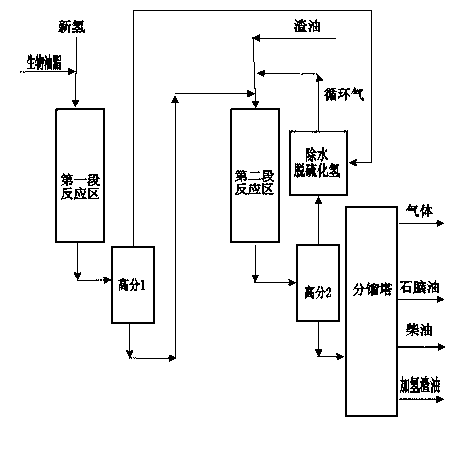

[0023] The method of the present invention is specifically as follows: one or several mixed oils and new hydrogen in the bio-grease pass through the first-stage hydrogenation reaction zone comprising at least two hydrogenation catalysts under hydrogenation operation conditions, and the obtained hydrogenation generates The gas separated from the oil in the high-pressure separator (referred to as high fraction) is mixed with the gas phase of the reaction product in the second-stage reaction zone for dehydration and dehydrogen sulfide treatment, and then used in the second-stage reaction zone. The obtained liquid fraction is mixed with residual oil and The circulating hydrogen is mixed into the second-stage reaction zone containing a series of residual oil hydrogenation catalysts, and the hydrogenated stream is separated in the high-pressure separator (abbreviated as high fraction), and the gas obtained is recycled in the second stage, and the obtained liquid is fractionated to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com