Six phase electrode alternating submerged arc furnace

A submerged arc furnace and six-electrode technology, which is applied in the direction of electric furnace heating, furnace, furnace components, etc., can solve the problems of difficult control of furnace conditions, poor temperature field balance, etc., and achieve low power consumption, easy production, and increased capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

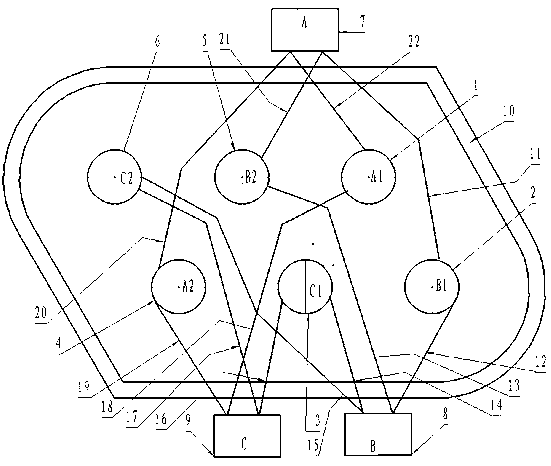

[0015] The layout and connection of electrodes, short nets and transformers are as follows: figure 1 As shown, among them: 1, 2, 3 are the first group of three-phase electrodes (A1, B1, C1), 4, 5, 6 are the second group of three-phase electrodes (A2, B2, C2), 7, 8, 9 are three single-phase transformers (A, B, C); 10 is the furnace wall; the first group of three-phase electrodes (A1, B1, C1) form an equilateral triangle and are arranged clockwise, and the second group of three-phase electrodes (A2 . ) on the extension line; the shape surrounded by the four furnace walls 10 of the furnace body is approximately rhombus, and the shortest distance between the electrodes of each phase and the inner wall of the furnace wall is equal; the primary side of the three single-phase transformers (A, B, C) and 35KV (or 110KV\220KV, etc.) grid connection, the secondary side is connected to the electrodes through large-section water cables, in which: the first group of three-phase electrodes ...

Embodiment 2

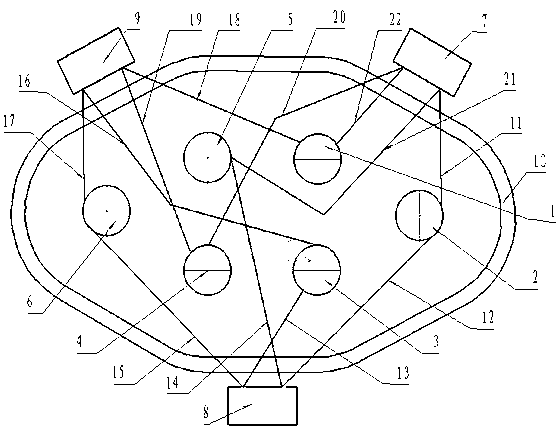

[0018] Embodiment two: Such as figure 2 As shown, the difference between embodiment two and embodiment one is as follows:

[0019] The three single-phase transformers (A, B, C) are symmetrically distributed in regular triangles, and the two sets of triangles are upside down, and the line connecting the vertices (B1, C2) of the two sets of triangles vertically bisects the bases of the two sets of triangles (A1- C1, A2-B2).

[0020] Embodiment 2 This layout method makes the distribution of the short network between the six-phase electrodes and the transformer more uniform, the impedance is more balanced, the power balance of the six-phase electrodes in the furnace is better, and the temperature field in the furnace is more evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com