Automobile tail gas waste heat recovery fused salt heat transfer and heat storage heat exchanger

A heat storage heat exchanger and waste heat recovery technology, applied in the fields of waste heat recovery, energy saving and environmental protection, can solve the problems of indirectness, randomness, cumbersomeness and large volume of automobile exhaust, and achieve superior heat storage performance and overcome the bulky volume. , the effect of large heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

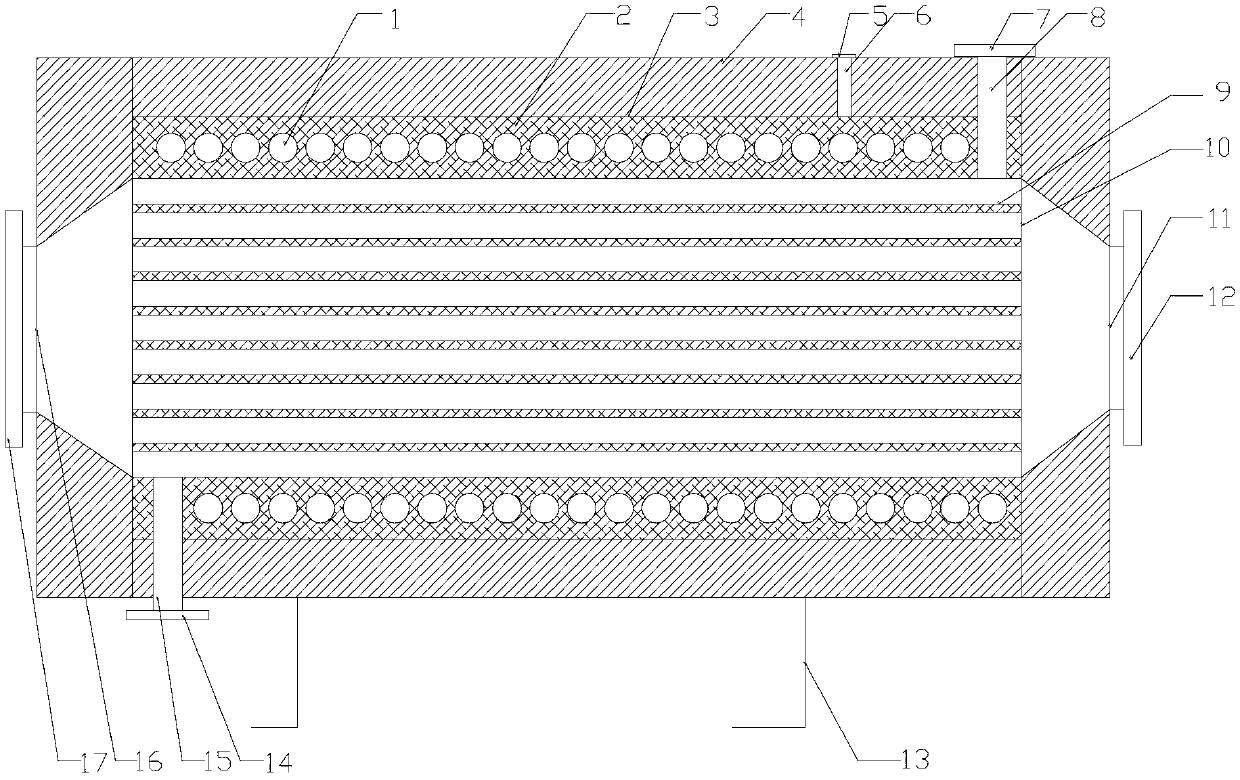

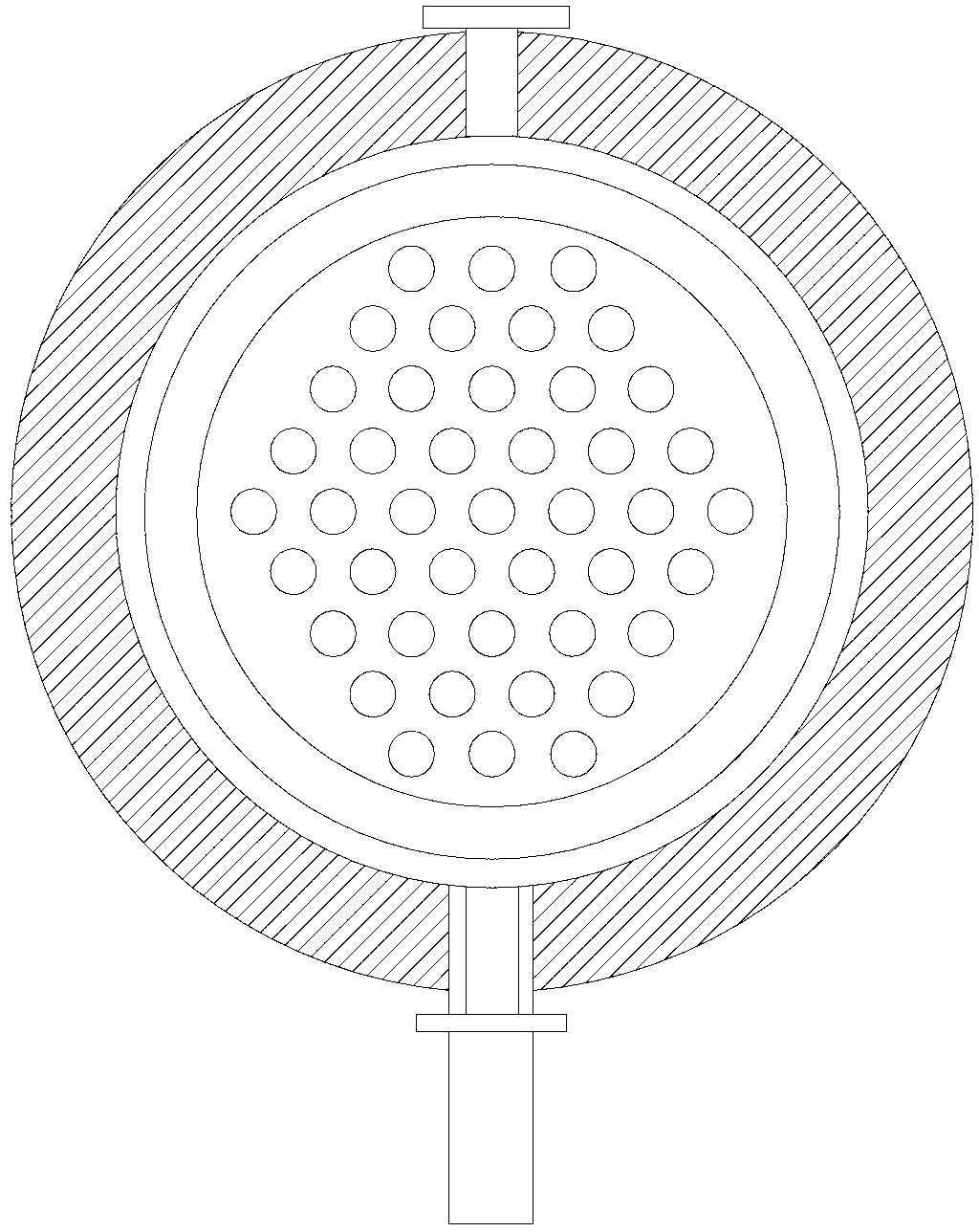

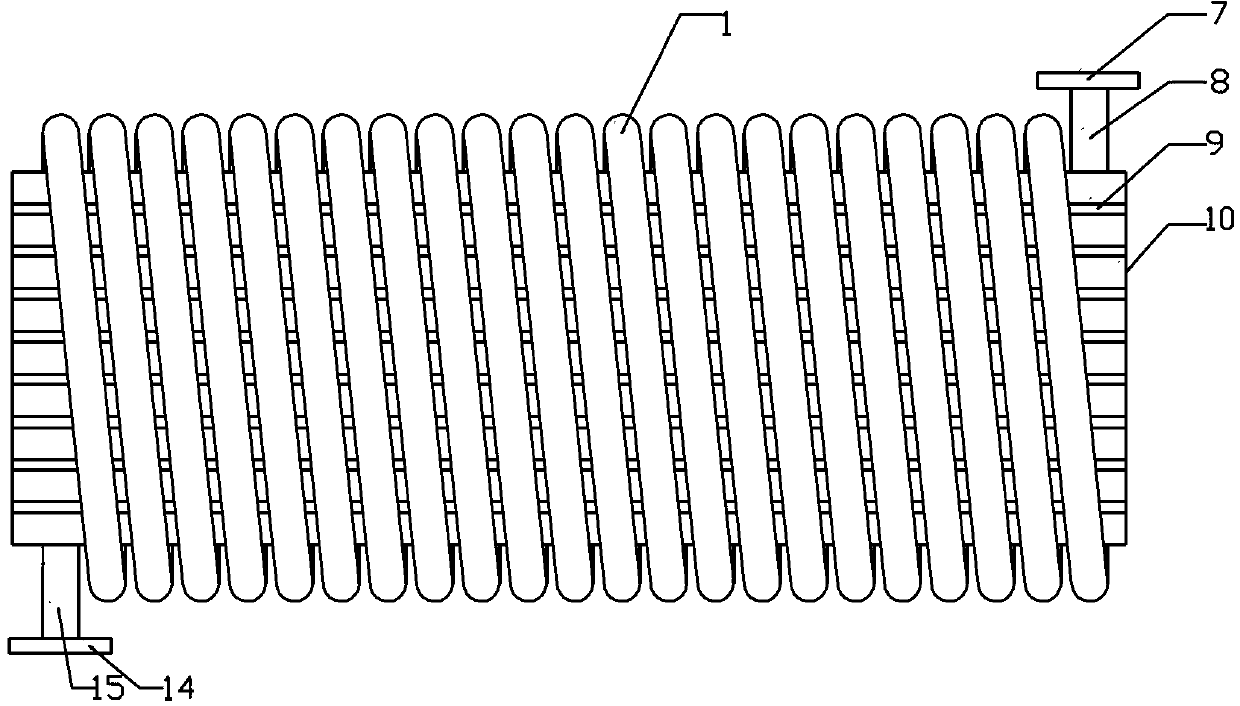

[0026] as attached figure 1 And attached figure 2 As shown, a heat transfer heat storage heat exchanger of molten salt for recovery of waste heat from automobile exhaust includes 43 stainless steel tubes for the flow of automobile exhaust. figure 2 As shown, the spiral coil tube (1), the front end cover (16), the rear end cover (11), the refrigerant inlet (8), the refrigerant outlet (14) and the cylinder wall (3) of the flowing refrigerant R245fa or R134a; A shell (2) containing phase-change material molten salt HITEC is also provided; a plurality of pipes (8) for flowing automobile exhaust gas are parallel to each other and fixed to the front end cover (16) and the rear end cover (11), and the flowing refrigerant The spiral coil (1) is wound on the outside of multiple pipes for flowing automobile exhaust, and between the multiple pipes (9) for flowing automobile exhaust, the pipes (9) for flowing automobile exhaust and the spiral coil for flowing refrigerant Between (1) ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap