Nanometer dipole solar cell and preparation method thereof

A solar cell and dipole technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as increased equipment and maintenance costs, cross-contamination, and limiting the production speed of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

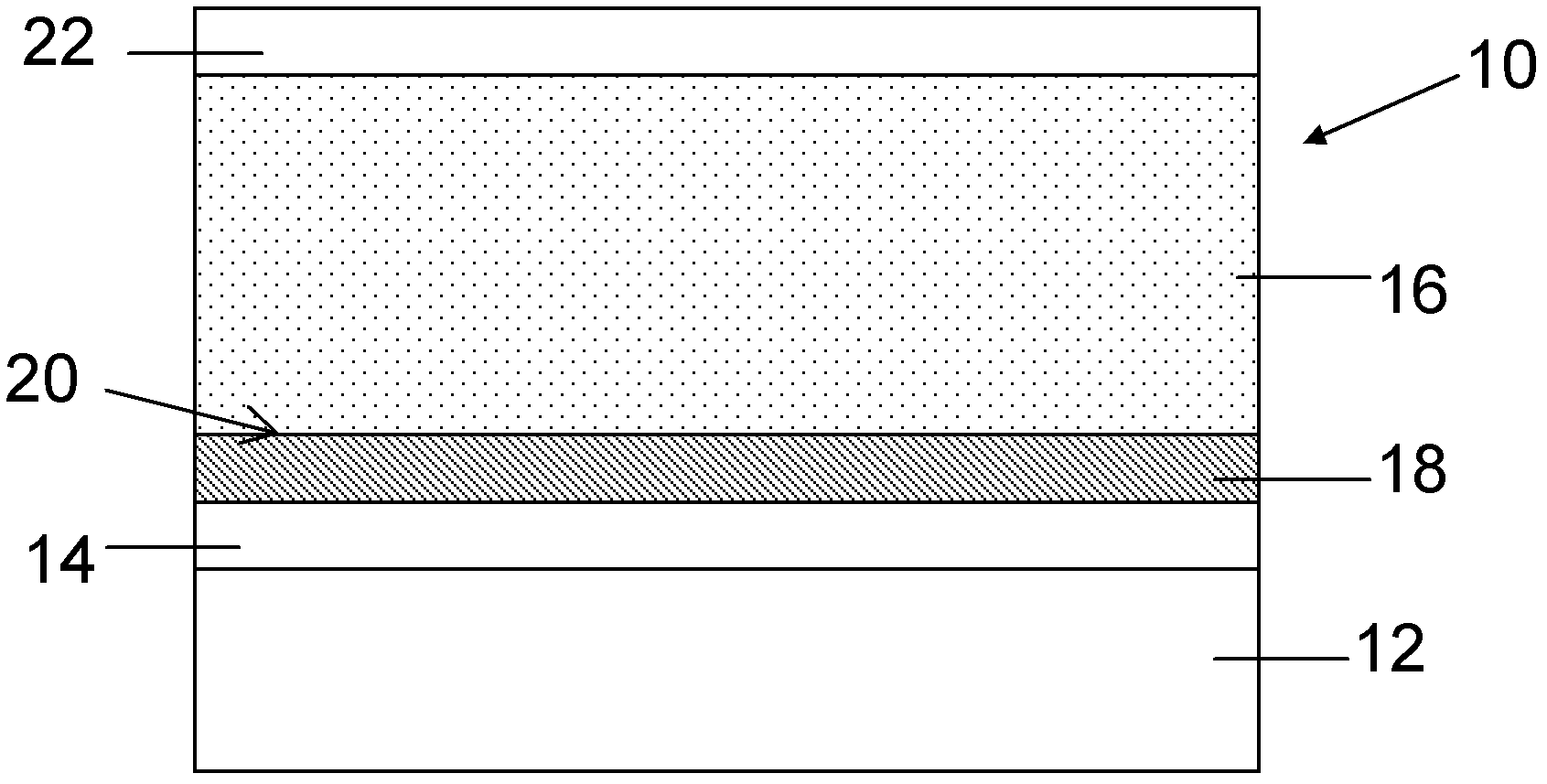

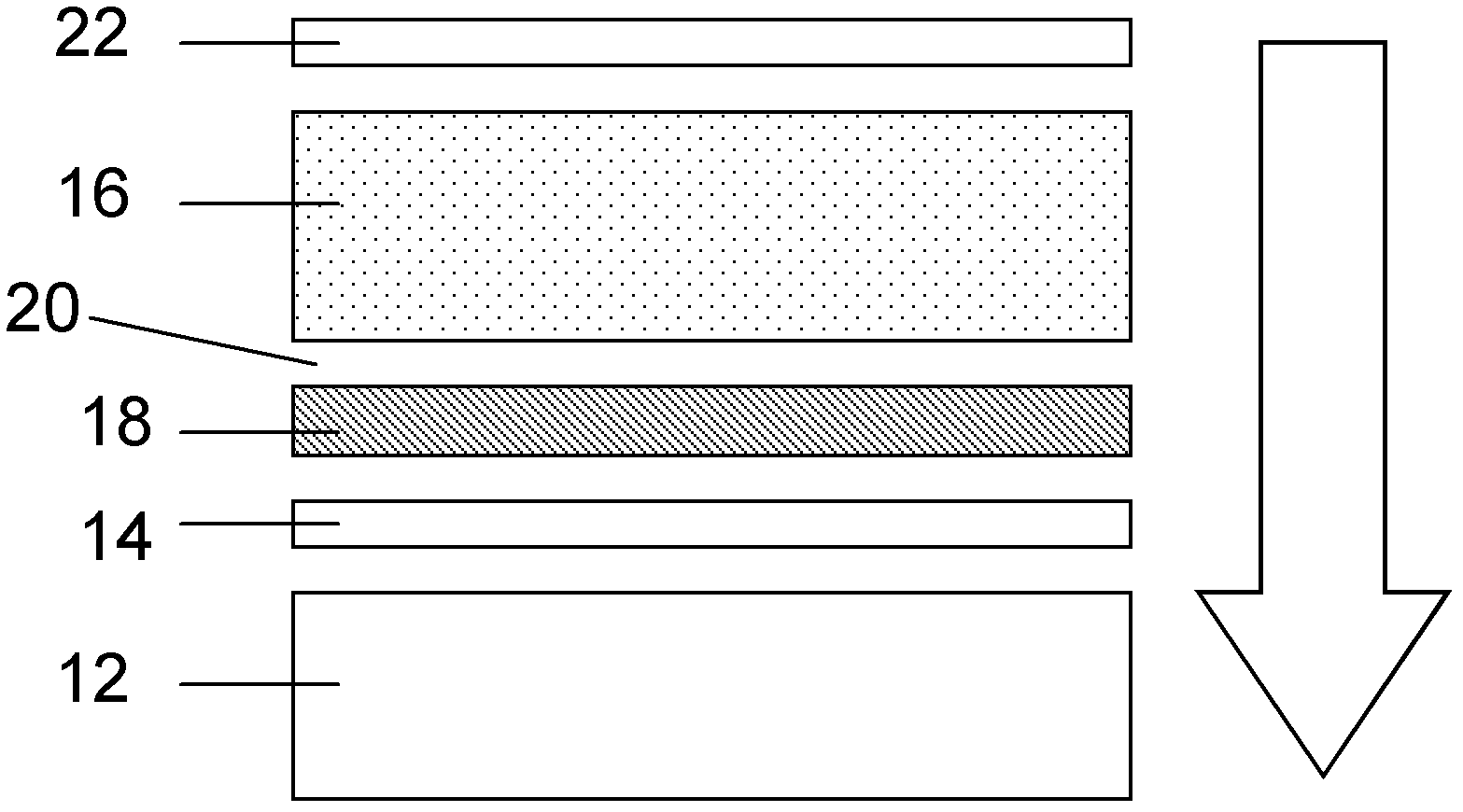

[0076] One of the preparation methods that the present invention prepares described nano-dipole solar cell comprises the following steps:

[0077] a) Clean the glass substrate covered with the first transparent conductive electrode layer, then sputter-deposit a mixed film of CdTe and CdS on the glass substrate, the thickness of the film is in the range of 0.2-20 μm, using The target material is CdS and CdTe mixed in a mass ratio of 1:30-1:2.5 and pressed;

[0078] b) Place the glass substrate deposited with CdTe and CdS mixed films on CdCl 2 Heat treatment in a mixed gas atmosphere with air for 5-120 minutes, and the heating temperature is 350-650 °C;

[0079] c) in CdCl 2 The second conductive electrode layer is deposited on the surface of the heat-treated film by sputtering to form the solar cell.

[0080] Error in implementing the steps described! Reference source not found. Simultaneously with b), applying a polarizing electric field on the first transparent conductiv...

Embodiment 1

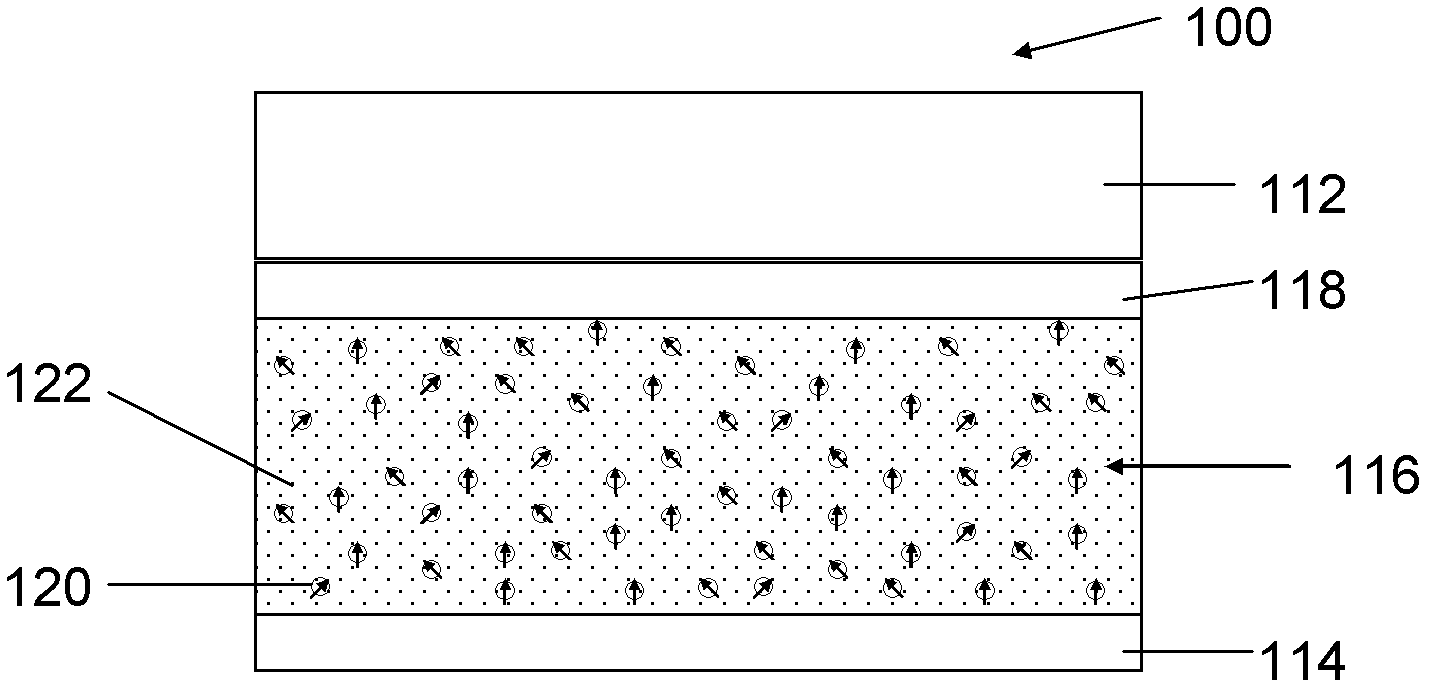

[0088] First install the 99.999% high-purity ZnO:Al target on the target position of the magnetron sputtering equipment; then send the cleaned glass substrate into the vacuum chamber of the thermal evaporation equipment and heat it to 200°C; Vacuum down to below 4×10 -4 Pa; fill the vacuum chamber with argon gas to 2Pa; turn on the RF sputtering power supply, and adjust the output power of the power supply to 2.5W / cm 2 , the distance between the target and the glass substrate is 10 cm; under this process condition, a 1.0 μm thick ZnO:Al transparent conductive film (TCO), that is, the first transparent conductive electrode layer, is deposited by sputtering.

[0089] Then mix CdS and CdTe according to the mass ratio of 1:30, at 6000N / cm 2The mixed target is pressed under a certain pressure, and the target made of the mixed target is installed on the target position of the magnetron sputtering equipment. Then the glass substrate deposited with the first transparent conductive e...

Embodiment 2

[0094] Install the 99.999% high-purity ZnO:Al target on the target position of the magnetron sputtering equipment; then send the cleaned glass substrate into the vacuum chamber of the thermal evaporation equipment and heat it to 200°C; pump the vacuum chamber Vacuum to below 4×10 -4 Pa; fill the vacuum chamber with argon gas to 2Pa; turn on the RF sputtering power supply, and adjust the output power of the power supply to 2.5W / cm 2 , the distance between the target and the glass substrate is 10 cm; under this process condition, a 1.0 μm thick ZnO:Al transparent conductive film (TCO), that is, the first transparent conductive electrode layer, is deposited by sputtering.

[0095] After mixing ZnTe and CdTe at a mass ratio of 1:30, at 10000N / cm 2 The mixed target is pressed under a certain pressure, and the target pressed from the mixed target is installed on the target position of the magnetron sputtering equipment. Then the TCO conductive glass substrate is sent into the vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com