Preparation method of hydrophobic material with surface modified by Fe3O4 nanoflower

A hydrophobic material and nanoflower technology, applied in the field of nanomaterials to achieve the effect of enhancing stability, stable performance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

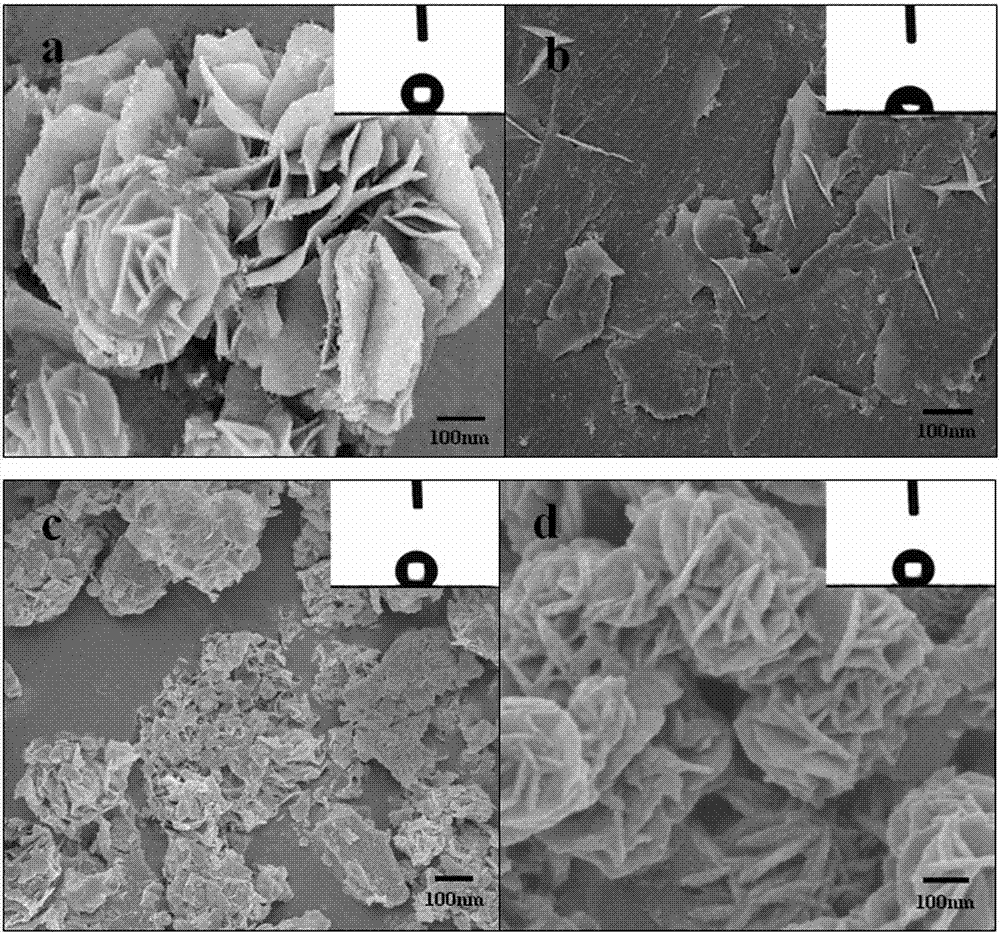

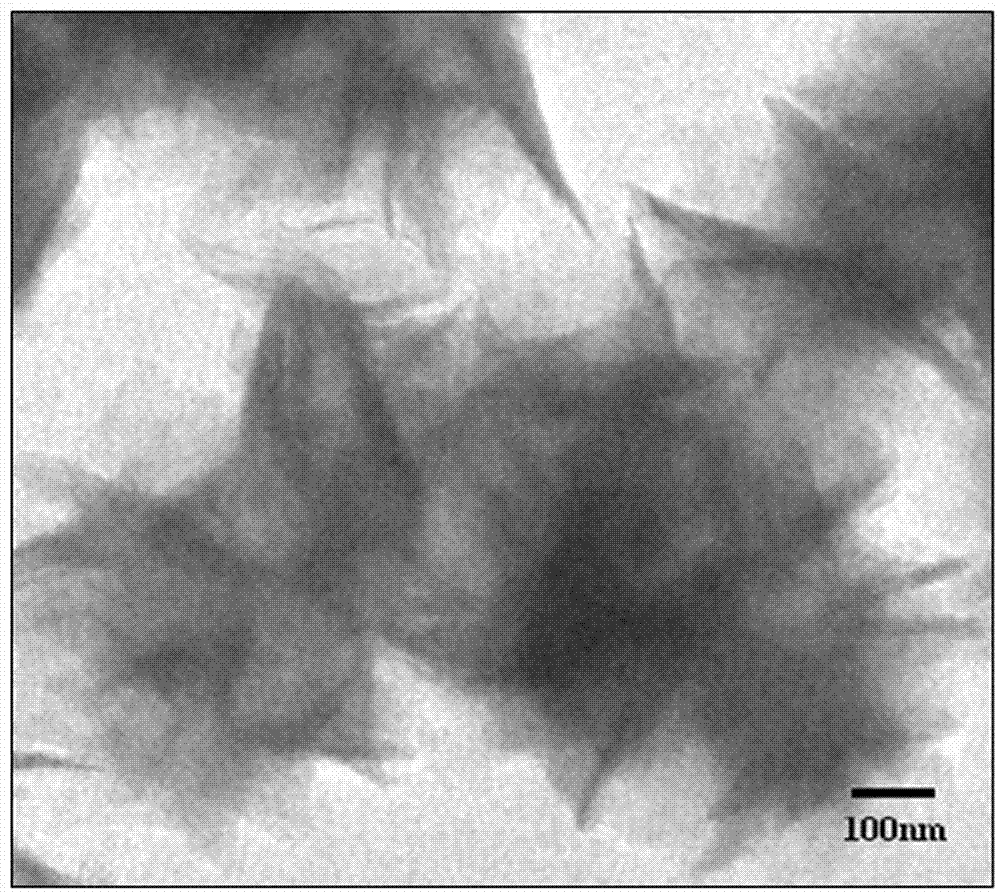

[0029] (1) Cut a 15mm×15mm×2mm pure iron sheet, polish it with sandpaper and wash it with dilute nitric acid and distilled water respectively to remove the oxide film on the surface of the pure iron sheet; immerse the iron sheet in 20mL of 0.5mol / L nitric acid solution into the reactor and put the reactor into a tube furnace. A magnet is placed on the outer bottom of the tube furnace, and the magnet attracts the above-mentioned iron sheet to the bottom of the reactor; heat the tube furnace to 50°C, and react the iron sheet with the nitric acid solution for 5 minutes.

[0030] (2) Slowly feed ammonia gas into the reactor until the pH of the reaction solution is 9; the temperature of the tube furnace is raised to 230°C and kept for 45 minutes.

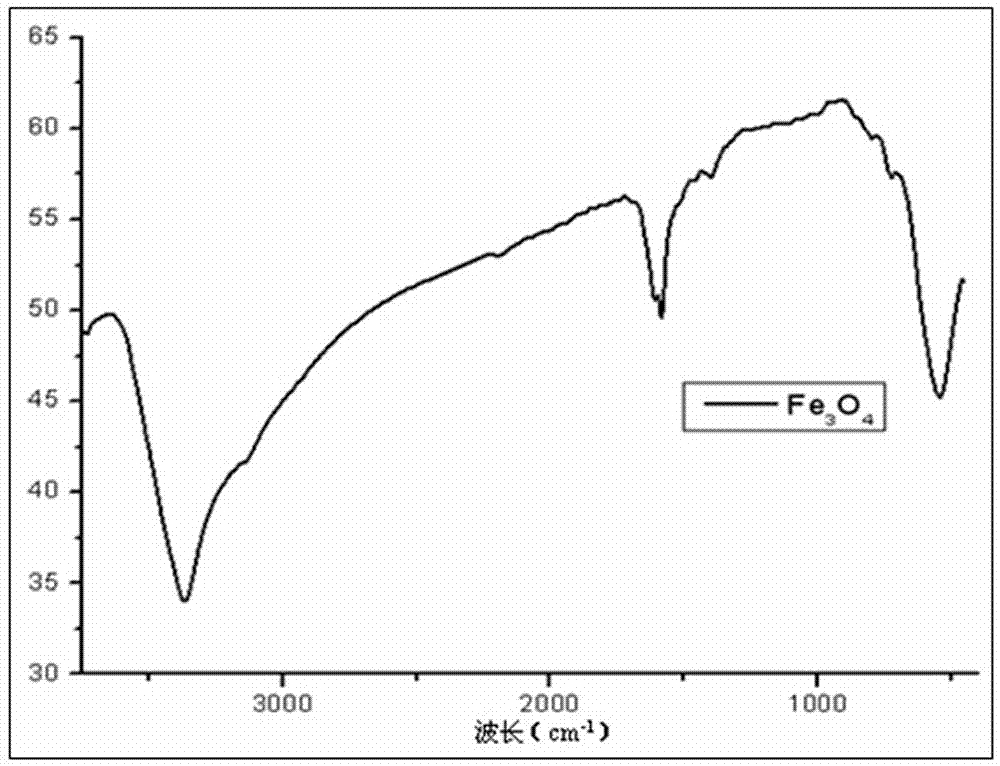

[0031] (3) Take out the reactor, cool to room temperature, rinse with distilled water and ethanol several times, and dry in vacuum to obtain Fe 3 o 4 Iron flakes modified by nanoflowers. The hydrophobic property of the product was tes...

Embodiment 2

[0034] (1) Cut a pure iron sheet of 15mm×15mm×2mm, polish it with sandpaper and wash it with dilute nitric acid and distilled water respectively to remove the oxide film on the surface of the pure iron sheet; immerse the iron sheet in 20mL of 0.5mol / L nitric acid solution into the reactor and put the reactor into a tube furnace. A magnet is placed on the outer bottom of the tube furnace, and the magnet attracts the above-mentioned iron sheet to the bottom of the reactor; heat the tube furnace to 50°C, and react the iron sheet with the nitric acid solution for 5 minutes.

[0035] (2) Slowly feed ammonia gas into the reactor until the pH of the reaction solution is 10; the temperature of the tube furnace is raised to 260°C and kept for 60 minutes.

[0036] (3) Take out the reactor, cool to room temperature, rinse with distilled water and ethanol several times, and dry in vacuum to obtain Fe 3 o 4 Iron flakes modified by nanoflowers. The hydrophobic property of the product was...

Embodiment 3

[0039] (1) Cut a pure iron sheet of 15mm×15mm×2mm, polish it with sandpaper and wash it with dilute nitric acid and distilled water respectively to remove the oxide film on the surface of the pure iron sheet; immerse the iron sheet in 20mL of 1.5mol / L nitric acid solution into the reactor and put the reactor into a tube furnace. A magnet is placed on the outer bottom of the tube furnace, and the magnet attracts the above-mentioned iron sheet to the bottom of the reactor; heat the tube furnace to 50°C, and react the iron sheet with the nitric acid solution for 5 minutes.

[0040] (2) Slowly feed ammonia gas into the reactor until the pH of the reaction solution is 11; the temperature of the tube furnace is raised to 260°C and kept for 60 minutes.

[0041] (3) Take out the reactor, cool to room temperature, rinse with distilled water and ethanol several times, and dry in vacuum to obtain Fe 3 o 4 Iron flakes modified by nanoflowers. The hydrophobic property of the product was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com