Preparation method of hydrophobic material with surface modified by Fe3O4 nanoflower

A technology of hydrophobic materials and nanoflowers, which is applied in the field of nanomaterials to achieve the effects of stable performance, enhanced stability and excellent hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

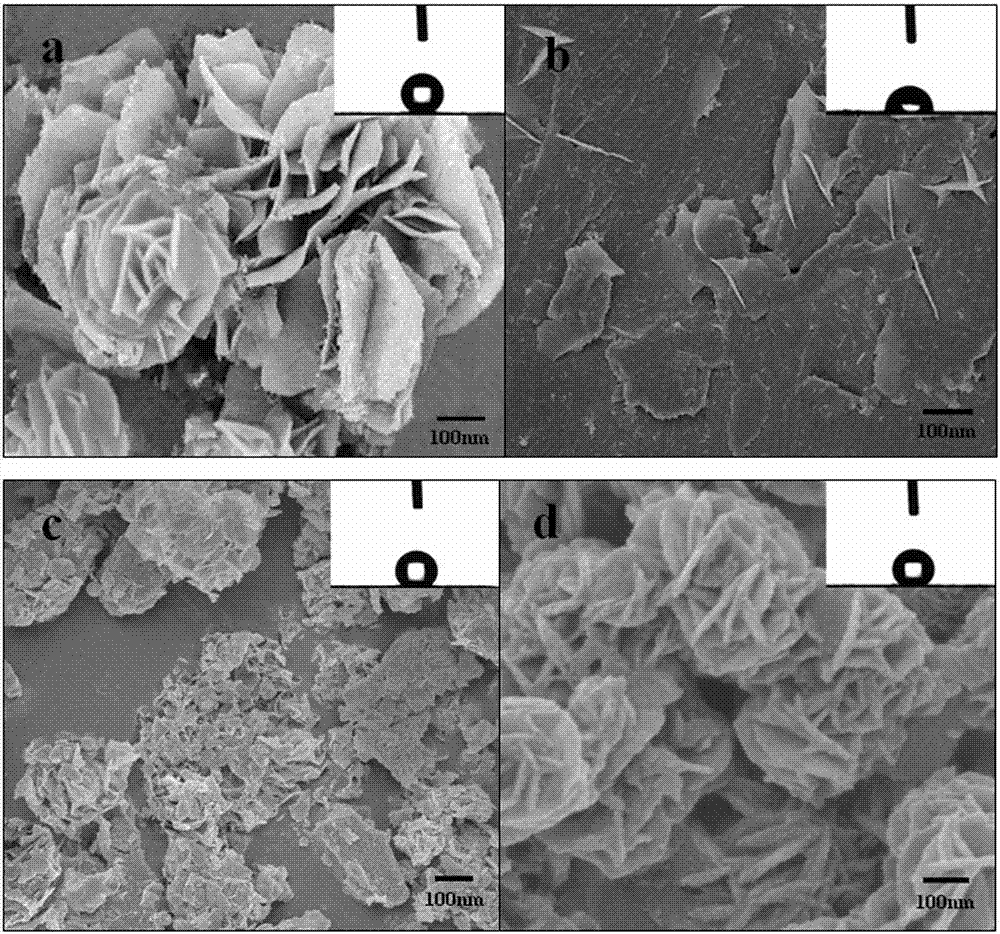

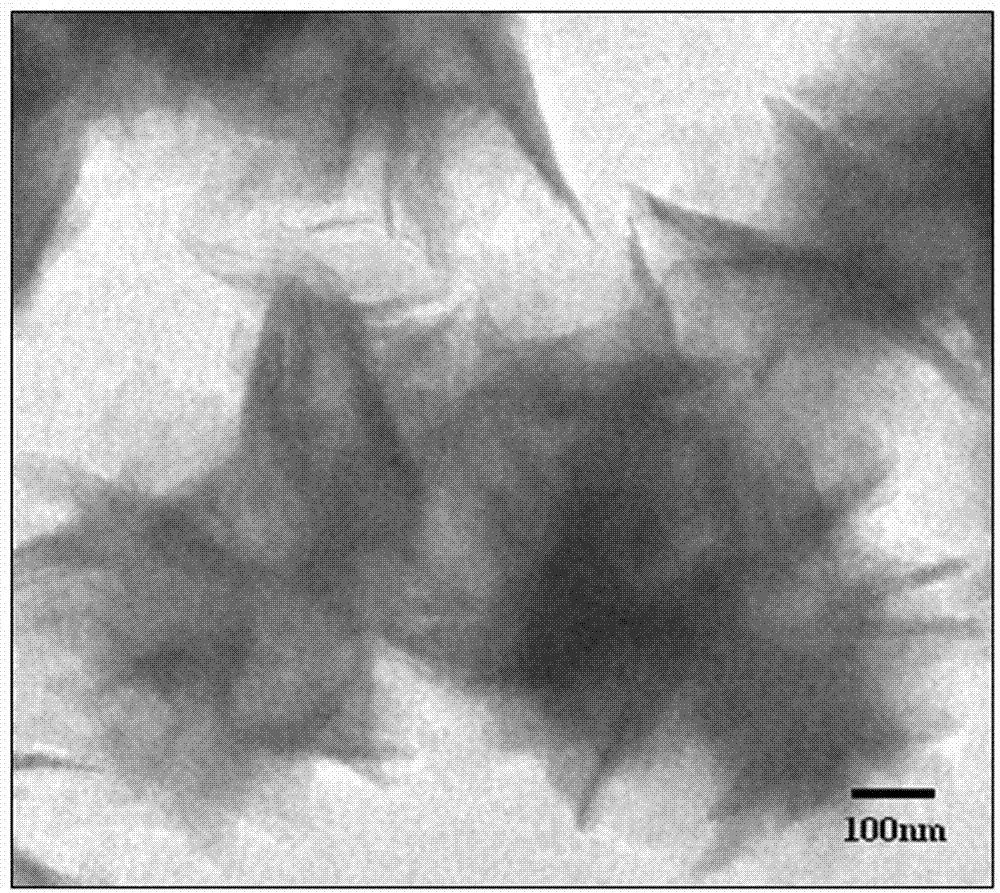

Embodiment 1

[0029] (1) Cut a pure iron sheet of 15mm×15mm×2mm, sand it with sandpaper and wash with dilute nitric acid and distilled water to remove the oxide film on the surface of the pure iron sheet; immerse the iron sheet in 20mL 0.5mol / L nitric acid solution And put the reactor into the tube furnace. A magnet is placed on the bottom of the outer side of the tube furnace, which attracts the iron pieces to the bottom of the reactor; heat the tube furnace to 50°C, and make the iron pieces react with the nitric acid solution for 5 minutes.

[0030] (2) Slowly pass ammonia gas into the reactor until the pH of the reaction solution is 9; the temperature of the tube furnace is increased to 230°C and maintained for 45 minutes.

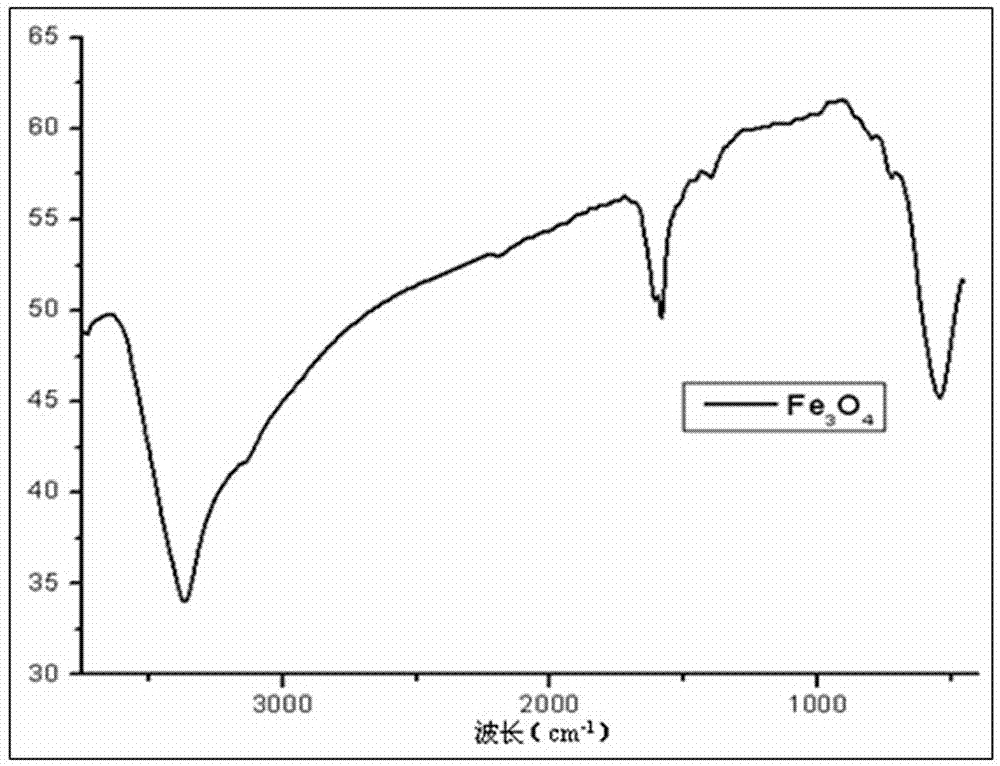

[0031] (3) Take out the reactor, cool to room temperature, rinse with distilled water and ethanol several times, and dry in vacuum to obtain Fe 3 O 4 Nano-flower modified iron sheet product. The hydrophobicity of the product was tested with a contact angle meter and foun...

Embodiment 2

[0034] (1) Cut the pure iron sheet of 15mm×15mm×2mm, polish with sandpaper and wash with dilute nitric acid and distilled water respectively to remove the oxide film on the surface of the pure iron sheet; immerse the iron sheet in 20mL 0.5mol / L nitric acid solution And put the reactor into the tube furnace. A magnet is placed on the bottom of the outer side of the tube furnace, which attracts the iron pieces to the bottom of the reactor; heat the tube furnace to 50°C, and make the iron pieces react with the nitric acid solution for 5 minutes.

[0035] (2) Slowly feed ammonia gas into the reactor until the pH of the reaction solution is 10; the temperature of the tube furnace is increased to 260°C and kept for 60 minutes.

[0036] (3) Take out the reactor, cool to room temperature, rinse with distilled water and ethanol several times, and dry in vacuum to obtain Fe 3 O 4 Nano-flower modified iron sheet product. A contact angle meter was used to test the hydrophobic properties of th...

Embodiment 3

[0039] (1) Cut pure iron flakes of 15mm×15mm×2mm, polish with sandpaper and wash with dilute nitric acid and distilled water respectively to remove the oxide film on the surface of the pure iron flakes; immerse the iron flakes in 20mL 1.5mol / L nitric acid solution And put the reactor into the tube furnace. A magnet is placed on the bottom of the outer side of the tube furnace, which attracts the iron pieces to the bottom of the reactor; heat the tube furnace to 50°C, and make the iron pieces react with the nitric acid solution for 5 minutes.

[0040] (2) Slowly pass ammonia gas into the reactor until the pH of the reaction solution is 11; the temperature of the tube furnace is increased to 260°C and kept for 60 minutes.

[0041] (3) Take out the reactor, cool to room temperature, rinse with distilled water and ethanol several times, and dry in vacuum to obtain Fe 3 O 4 Nano-flower modified iron sheet product. A contact angle meter was used to test the hydrophobic properties of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com