Polyethylene material capable of crosslinking in natural light as well as preparation method and using method thereof

A technology of natural light and polyethylene, applied in the field of polyethylene material and its preparation, can solve the problems of high energy consumption and high cross-linking cost, and achieve the effects of excellent mechanical properties, reduced cross-linking cost and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

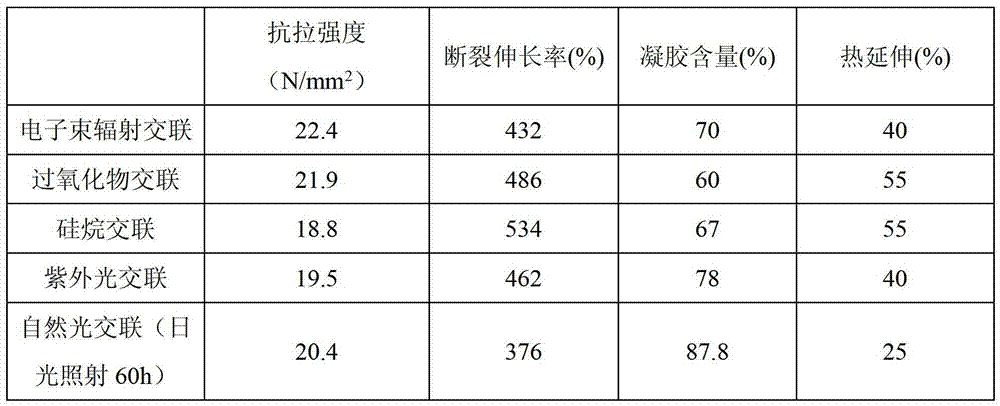

[0015] Embodiment 1: In this embodiment, a kind of polyethylene material that can be crosslinked by natural light is composed of 100 parts by weight of dry polyethylene resin, 0.02 to 0.8 parts of photoinitiator, 1 to 8 parts of auxiliary crosslinking agent and 0.01 to 0.4 part of antioxidant is made, and the mass ratio of wherein said photoinitiator and co-crosslinking agent is 1:(70~130), and the mass ratio of described photoinitiator and antioxidant is 1:(2 ~13).

[0016] The natural light cross-linkable polyethylene material described in this embodiment does not require special cross-linking equipment, and uses natural light for effective cross-linking, which reduces cross-linking costs.

specific Embodiment approach 2

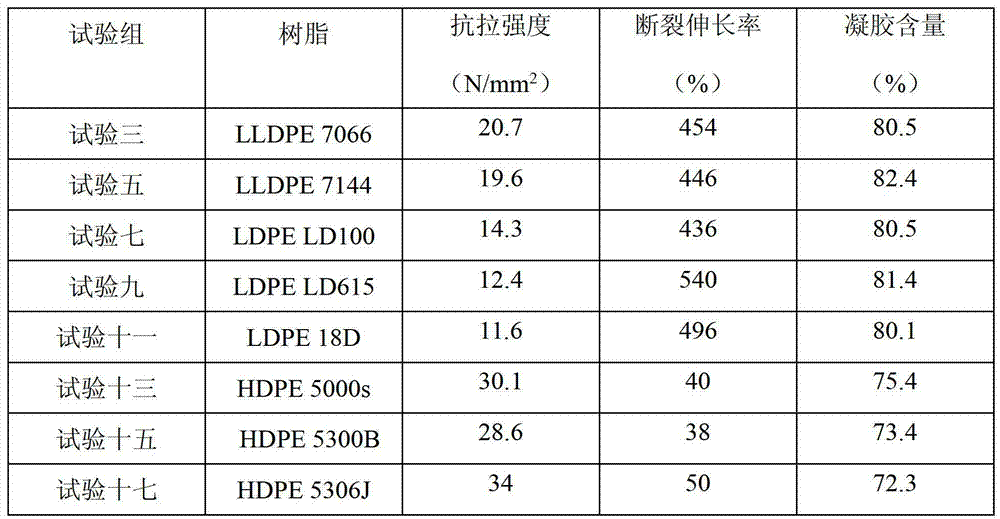

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the polyethylene resin is LLDPE (Linear Low Density Polyethylene) 7042, LLDPE (Linear Low Density Polyethylene) 7066, LLDPE (Linear Low Density Polyethylene) ) 7144, LDPE (low density polyethylene) LD100, LDPE (low density polyethylene) LD615, LDPE (low density polyethylene) 18D, HDPE (high density polyethylene) 5000s, HDPE (high density polyethylene) 5300B and HDPE ( High-density polyethylene) 5306J in one or a mixture of several. Others are the same as in the first embodiment.

[0018] When the polyethylene resin described in this embodiment is a mixture, each component is mixed in any ratio.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the photoinitiator is 2-hydroxy-methylphenyl propane-1-one (Darocur1173), 1-hydroxycyclohexylphenyl Methanone (Irgacure184), 2-methyl-1-(4-methylthiophenyl)-2-morpholino-1-propanone (Irgacure907), benzoyl formate (Irgacure754), benzoin dimethyl ether ( Photoinitiator 651), benzphenone, aroylphosphine oxide, 4-methylbenzophenone (MBZ), benzophenone-3,4-chlorobenzophenone (photoinitiator 1046), 2,4,6-Trimethylbenzophenone, ethyl 4-dimethylaminobenzoate, 2-hydroxy-methylphenylpropan-1-one (Darocur1173) derivatives, 1-hydroxycyclohexylbenzene Methyl ketone (Irgacure184) derivatives, 2-methyl-1-(4-methylthiophenyl)-2-morpholino-1-propanone (Irgacure907) derivatives, benzoyl formate (Irgacure754) derivatives substances, benzoin dimethyl ether (photoinitiator 651) derivatives, benzphenone derivatives, aroylphosphine oxide derivatives, 4-methylbenzophenone (MBZ) derivat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com