Hydraulic cyclone anaerobic digestion tower and using method thereof

A technology of anaerobic digestion and hydrocyclone, which is used in biochemical equipment and methods, biochemical instruments, biological sludge treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

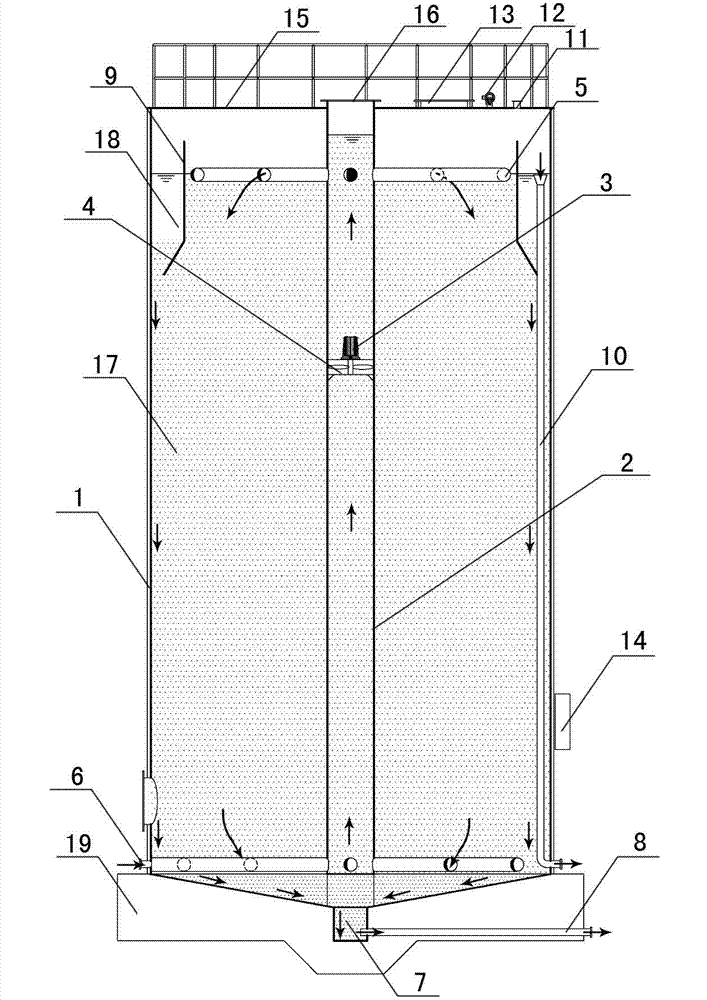

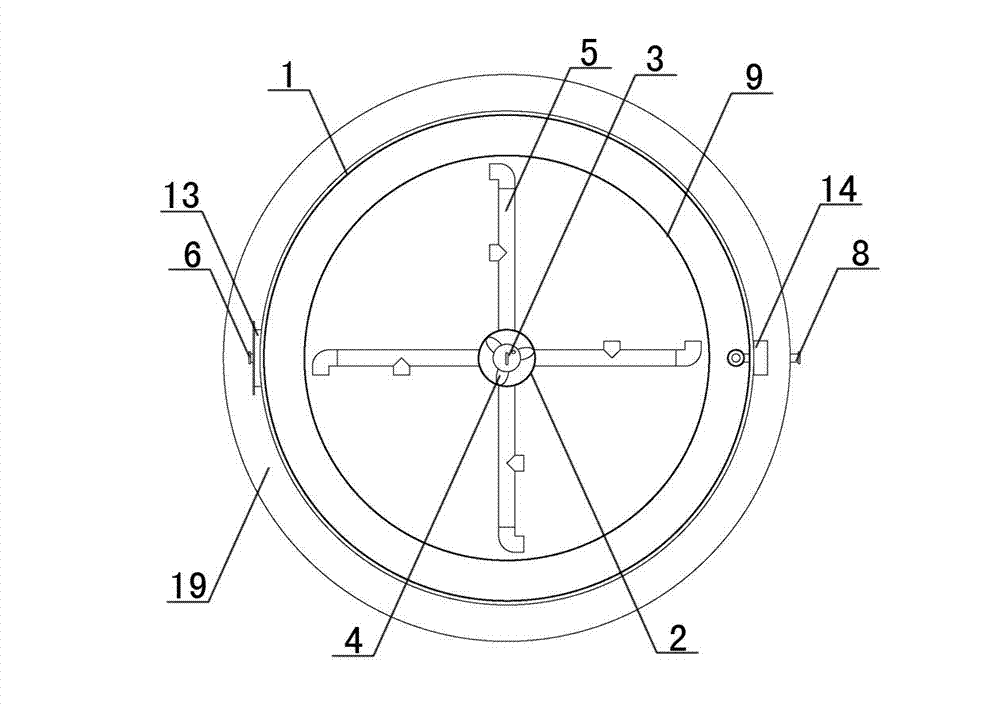

[0022] Examples see figure 1 As shown, the tower body 1 is a cylindrical body with an inverted conical bottom, and the bottom of the inverted tapered cylindrical cylinder is fixed on the support 19. The diameter of the tower body is 4 to 8 meters, and the height is 10 to 18 meters. There is a closed top cover 15 on the top of the tower body 1, and the outside is treated with overall heat preservation. The center of the tower body 1 has a vertically placed hollow guide tube 2 equipped with a sealing cover 16, with a diameter of 600-1200 mm. The upper end of the guide tube 2 is higher than the top cover 15, and the lower end is connected to the inverted conical bottom of the tower body 1; a submersible motor 3 is fixed on the inner wall of the middle part of the guide tube, and the power is 2.2 to 11 kilowatts. The submersible motor 3 Connected with the lifting impeller 4, the side wall of the guide tube 2 communicates with the upper and lower layers of radially distributed guid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com