Preparation method of copper-chrome alloy

A copper-chromium alloy and charging technology, which is applied in the field of alloy material preparation, can solve the problems of high requirements on process parameters such as operating temperature, can not effectively meet energy-saving requirements, and high energy consumption, and achieves reduction in the number of pores and heat loss. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

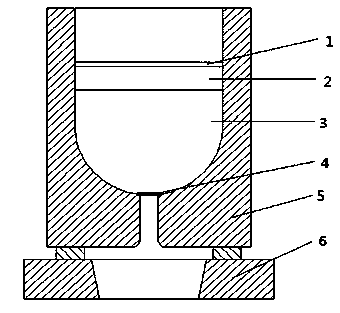

[0033] Clean and assemble the charged graphite mold and forming mold, put the baffle into the bottom of the graphite mold, and then preheat the mold, the preheating temperature is 200-300°C, and the preheating time is about 15 minutes.

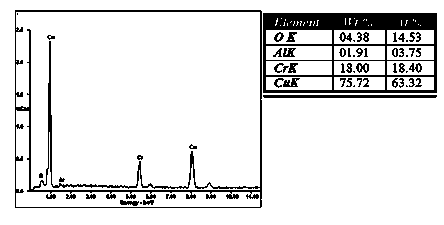

[0034] The raw materials were weighed, among which aluminum powder (200 mesh), chromium trioxide (200 mesh) and 55% copper oxide (100 mesh) were all industrial grade. Magnesium Sulfate (MgSO 4 ) can not only provide heat, but also have a slagging effect, and the slagging agent is selected as calcium fluoride (CaF 2 ); Raw material weight ratio is (Wt%):

[0035]

[0036] First put the material of layer A into the mixer, and the mixing time is 3 minutes. Since the mixing process is easy to generate heat, in order to ensure that the heat in this process is fully dissipated and the operation safety is improved, the mixer is kept in an intermittent working state. , that is, mixing for about 15 seconds, stopping for about 10 seconds, mixing fo...

Embodiment 2

[0038] Clean and assemble the charged graphite mold and forming mold, put the baffle into the bottom of the graphite mold, and then preheat the mold, the preheating temperature is 200-300°C, and the preheating time is about 15 minutes.

[0039] The raw materials were weighed, wherein aluminum powder, chromium trioxide and 55% copper oxide were all industrial grades. Magnesium Sulfate (MgSO 4 ) can not only provide heat, but also have a slagging effect, and the slagging agent is selected as calcium fluoride (CaF 2 ); Raw material weight ratio is (Wt%):

[0040]

[0041]First put the material of layer A into the mixer, and the mixing time is 3 minutes. Since the mixing process is easy to generate heat, in order to ensure that the heat in this process is fully dissipated and the operation safety is improved, the mixer is kept in an intermittent working state. , that is, mixing for about 15 seconds, stopping for about 10 seconds, mixing for about 15 seconds, stopping for 10 s...

Embodiment 3

[0043] Clean and assemble the charged graphite mold and forming mold, put the baffle into the bottom of the graphite mold, and then preheat the mold, the preheating temperature is 200-300°C, and the preheating time is about 15 minutes.

[0044] The raw materials were weighed, wherein aluminum powder, chromium trioxide and 55% copper oxide were all industrial grades. Magnesium Sulfate (MgSO 4 ) can not only provide heat, but also have a slagging effect, and the slagging agent is selected as calcium fluoride (CaF 2 ); Raw material weight ratio is (Wt%):

[0045]

[0046] First put the material of layer A into the mixer, and the mixing time is 3 minutes. Since the mixing process is easy to generate heat, in order to ensure that the heat in this process is fully dissipated and the operation safety is improved, the mixer is kept in an intermittent working state. , that is, mixing for about 15 seconds, stopping for about 10 seconds, mixing for about 15 seconds, stopping for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com