Anti-condensation outer insulative wall body structure

A wall structure and external thermal insulation technology, applied in thermal insulation, building thermal insulation materials, walls, etc., can solve problems such as airtightness, moisture condensation, mildew, etc., achieve small thermal conductivity, good moisture permeability, and reduce heat loss. The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

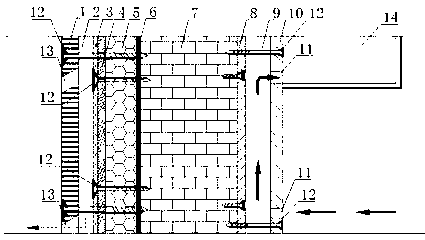

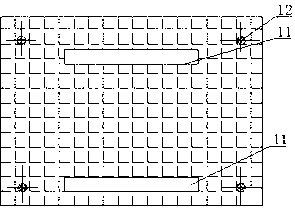

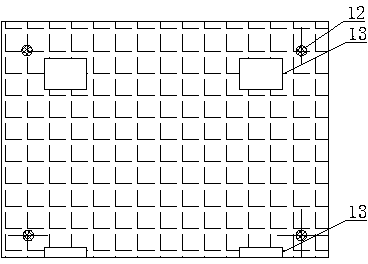

[0026] 1. Embodiment: figure 1 It is a schematic diagram of the external thermal insulation wall structure of the present invention, as figure 1 As shown, from outside to inside are cement board 1, outer air layer 2, polymer elastic coating material 3, plywood 4, flame-retardant insulation material 5, cement mortar leveling 6, base load-bearing wall 7, polyethylene film 8. Inner air layer 9. Gypsum board 10.

[0027] The ratio of the sum of the upper and lower opening areas of the gypsum board to the volume of the inner air layer is not less than 0.05 (1 / m), the thickness of the air layer is between 10mm and 60mm, take 20mm, clean the base surface, and place it in the interior of the base load-bearing wall Adhere to a layer of polyethylene film on the side for waterproofing and fix it, and then fix the gypsum board on the load-bearing wall of the base layer with bolts 12. The fixing gap must be sealed with a sealing material, and the distance between the fixing parts is 200mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com