Method and device for fluorescence interference microscopic measurement based on stimulated radiation

A technology of stimulated radiation and interference microscopy, applied in measurement devices, optical devices, instruments, etc., can solve the problems that the detection system cannot achieve high NA and high slope surface detection, and the detection light is difficult to return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

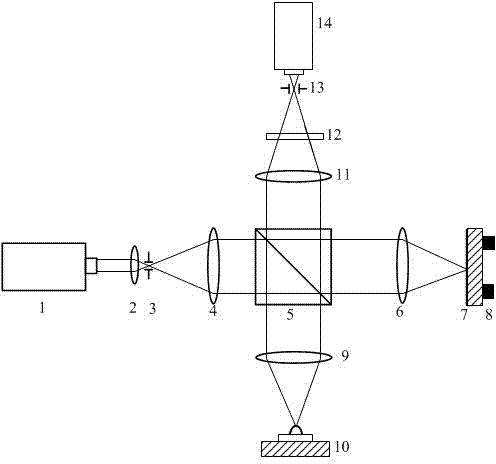

[0022] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] The fluorescence interference microscopic measurement method based on stimulated radiation of the present embodiment comprises the following steps:

[0024] a, adopt the multi-source organic molecular beam deposition OMBD system, adopt the same process to vapor-deposit the organic thin film, vapor-deposit the same kind of fluorescent organic thin film with the same thickness on the surface of the test piece 10 and the reference mirror 7, and the test piece 10 The surface is changed from the original smooth surface to the diffuse surface;

[0025] b. The measured surface 10 and the reference mirror 7 are excited by the monochromatic detection laser, and the surface radiates quasi-monochromatic light with the same central wavelength and the same spectral width range. The central wavelength of the quasi-monochromatic light is 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com