Method of online monitoring for high-voltage switch contact temperature rise

A contact temperature rise, high-voltage switch technology, applied in thermometers, measuring devices, measuring heat and other directions, can solve the problems of high price of optical fiber thermometers, aging of optical fiber insulation, troublesome installation and renovation of optical fiber thermometers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An online monitoring method for temperature rise of high-voltage switch contacts, characterized in that:

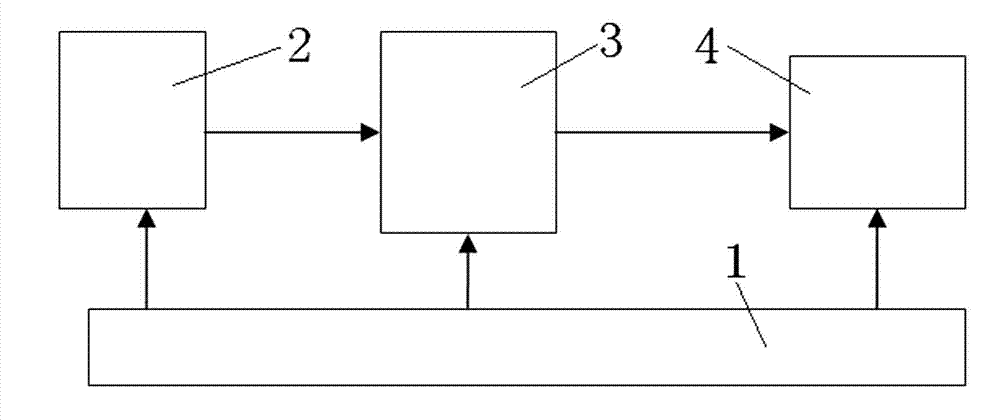

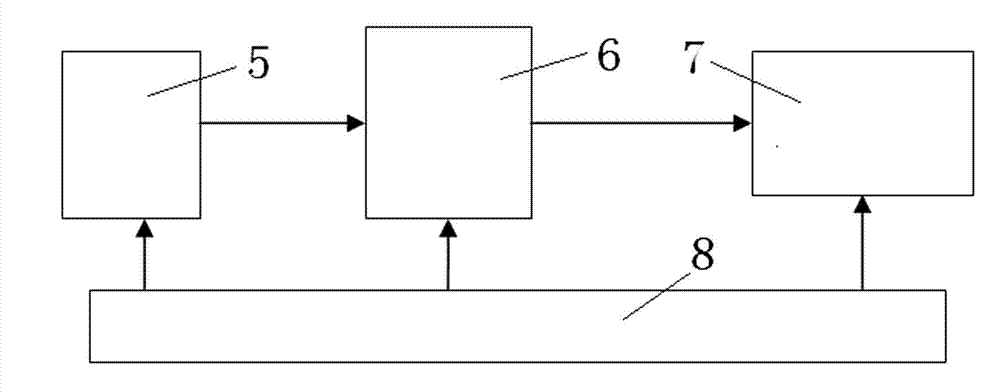

[0021] 1. The online monitoring equipment used is an online monitoring device for the temperature rise of high-voltage switch contacts, including the power supply circuit 1 of the transmitting part, the temperature acquisition circuit 2, the microprocessor of the transmitting part 3, the wireless transmitting circuit 4, the wireless receiving circuit 5, and the receiving part. The microprocessor 6, the display circuit 7 of the receiving part and the power supply circuit 8 of the receiving part.

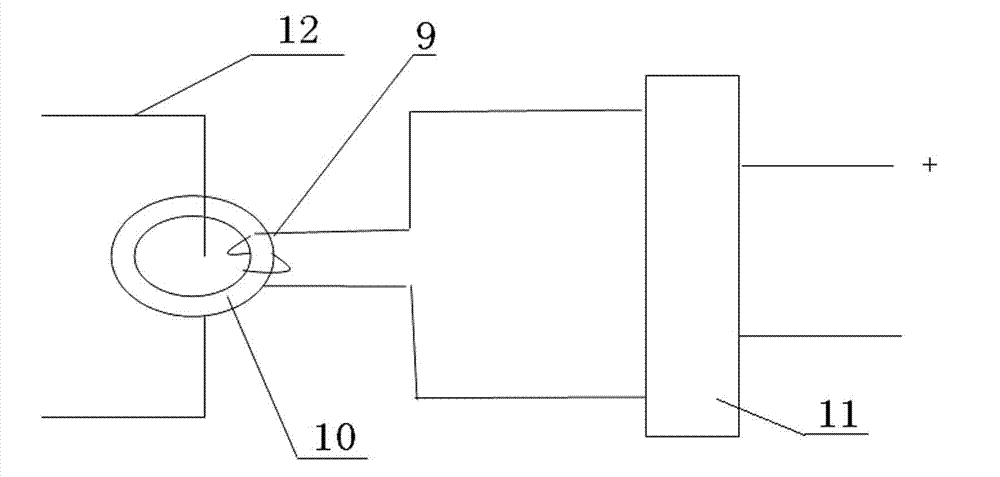

[0022] The power supply circuit 1 of the transmitting part is composed of a current induction coil 9, an annular iron core 10 and a voltage conversion module 11. The current induction coil 9 is wound on the annular iron core 10, and the two leads of the current induction coil 9 correspond to the voltage conversion module 11. The connection terminal is connected, and the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com