1.5V chargeable lithium battery and preparation method thereof

A technology for rechargeable lithium batteries and battery cells, applied in lithium batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve problems such as uneven current density at the SEI interface, battery safety issues, etc., and achieve good thermal stability and Anti-puncture strength, save production cost, and improve the effect of lithium ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example illustrates the preparation of an 18650 rechargeable lithium ion battery with a voltage of 1.5V provided by the present invention.

[0039] (1) Preparation of lithium titanate cathode

[0040] Dissolve 3 g of polyvinylidene fluoride (PVDF) in 120 mL of N-methylpyrrolidone (NMP), then add 24 g of lithium titanate powder and 3 g of carbon black to it, and then stir in vacuum for 6 hours to form a uniform positive electrode slurry. Coat or spray the slurry on one side of the aluminum foil with a thickness of 16μm and a width of 60mm (which should be cleaned and welded with tabs), dried at 120℃, and then coated on the slurry The other side of the aluminum foil is rolled to obtain a lithium titanate positive electrode with a thickness of 116 μm. The surface density of the lithium titanate active material is 15 mg / cm. 2 .

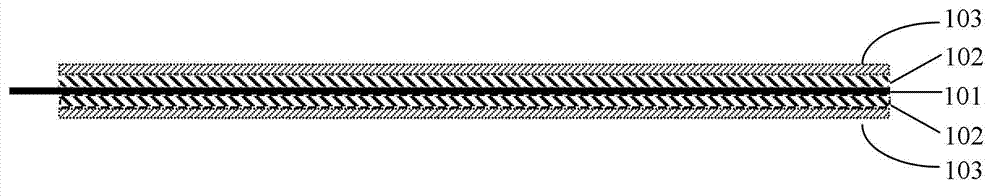

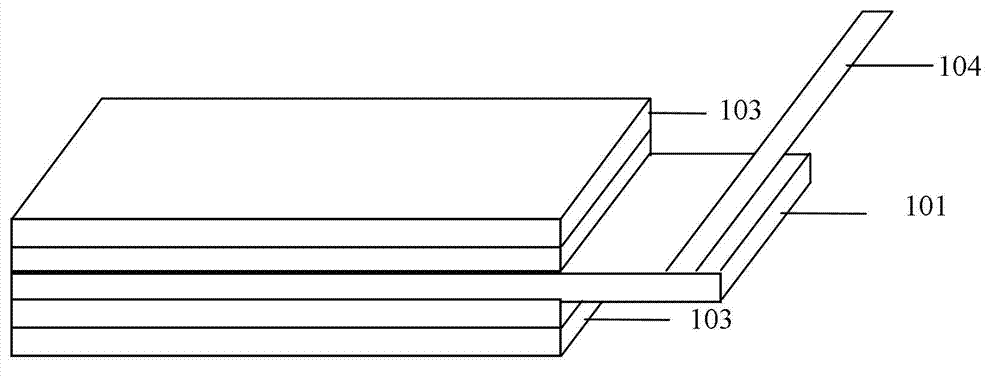

[0041] (2) Preparation of composite layer of lithium titanate cathode and lithium fast ion conductor separator

[0042] Dissolve 6g PVDF in 270mL NM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com